PDF Publication Title:

Text from PDF Page: 163

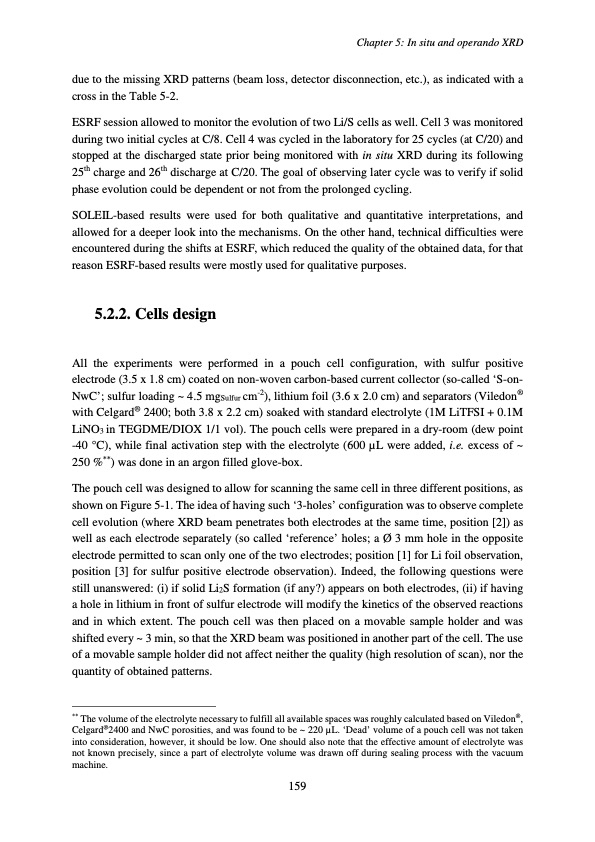

due to the missing XRD patterns (beam loss, detector disconnection, etc.), as indicated with a cross in the Table 5-2. ESRF session allowed to monitor the evolution of two Li/S cells as well. Cell 3 was monitored during two initial cycles at C/8. Cell 4 was cycled in the laboratory for 25 cycles (at C/20) and stopped at the discharged state prior being monitored with in situ XRD during its following 25th charge and 26th discharge at C/20. The goal of observing later cycle was to verify if solid phase evolution could be dependent or not from the prolonged cycling. SOLEIL-based results were used for both qualitative and quantitative interpretations, and allowed for a deeper look into the mechanisms. On the other hand, technical difficulties were encountered during the shifts at ESRF, which reduced the quality of the obtained data, for that reason ESRF-based results were mostly used for qualitative purposes. 5.2.2. Cells design All the experiments were performed in a pouch cell configuration, with sulfur positive electrode (3.5 x 1.8 cm) coated on non-woven carbon-based current collector (so-called ‘S-on- NwC’; sulfur loading ~ 4.5 mgSulfur cm-2), lithium foil (3.6 x 2.0 cm) and separators (Viledon® with Celgard® 2400; both 3.8 x 2.2 cm) soaked with standard electrolyte (1M LiTFSI + 0.1M LiNO3 in TEGDME/DIOX 1/1 vol). The pouch cells were prepared in a dry-room (dew point -40 °C), while final activation step with the electrolyte (600 μL were added, i.e. excess of ~ 250 %**) was done in an argon filled glove-box. The pouch cell was designed to allow for scanning the same cell in three different positions, as shown on Figure 5-1. The idea of having such ‘3-holes’ configuration was to observe complete cell evolution (where XRD beam penetrates both electrodes at the same time, position [2]) as well as each electrode separately (so called ‘reference’ holes; a Ø 3 mm hole in the opposite electrode permitted to scan only one of the two electrodes; position [1] for Li foil observation, position [3] for sulfur positive electrode observation). Indeed, the following questions were still unanswered: (i) if solid Li2S formation (if any?) appears on both electrodes, (ii) if having a hole in lithium in front of sulfur electrode will modify the kinetics of the observed reactions and in which extent. The pouch cell was then placed on a movable sample holder and was shifted every ~ 3 min, so that the XRD beam was positioned in another part of the cell. The use of a movable sample holder did not affect neither the quality (high resolution of scan), nor the quantity of obtained patterns. ** The volume of the electrolyte necessary to fulfill all available spaces was roughly calculated based on Viledon®, Celgard®2400 and NwC porosities, and was found to be ~ 220 μL. ‘Dead’ volume of a pouch cell was not taken into consideration, however, it should be low. One should also note that the effective amount of electrolyte was not known precisely, since a part of electrolyte volume was drawn off during sealing process with the vacuum machine. Chapter 5: In situ and operando XRD 159PDF Image | Accumulateur Lithium Soufre

PDF Search Title:

Accumulateur Lithium SoufreOriginal File Name Searched:

WALUS_2015_archivage.pdfDIY PDF Search: Google It | Yahoo | Bing

Sulfur Deposition on Carbon Nanofibers using Supercritical CO2 Sulfur Deposition on Carbon Nanofibers using Supercritical CO2. Gamma sulfur also known as mother of pearl sulfur and nacreous sulfur... More Info

CO2 Organic Rankine Cycle Experimenter Platform The supercritical CO2 phase change system is both a heat pump and organic rankine cycle which can be used for those purposes and as a supercritical extractor for advanced subcritical and supercritical extraction technology. Uses include producing nanoparticles, precious metal CO2 extraction, lithium battery recycling, and other applications... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |