PDF Publication Title:

Text from PDF Page: 010

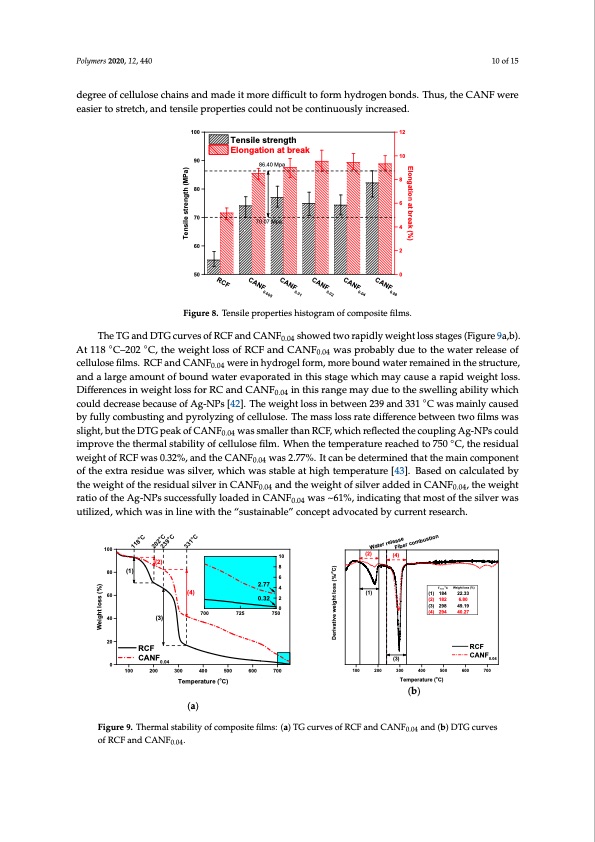

Due to the good affinity between the coupled Ag‐NPs and cellulose, Ag‐NPs acted as an enhancer, making the tensile strength of CANF superior to RCF. The tensile strength of films from 55 MPa increased to exceed 70 MPa (reach up to 86.4 MPa), and the elongation at break increased more than 50% (Figure 8). The values were better than the silver‐loaded cellulose derivative films Polymers 2020, 12, 440 10 of 15 published previously [41]. However, the tensile properties showed the complex changes with the increase in content of Ag‐NPs. It may attribute to the decline of cellulose crystallinity, which reduced degree of cellulose chains and made it more difficult to form hydrogen bonds. Thus, the CANF were the order degree of cellulose chains and made it more difficult to form hydrogen bonds. Thus, the easier to stretch, and tensile properties could not be continuously increased. CANF were easier to stretch, and tensile properties could not be continuously increased. 100 90 80 70 60 50 Tensile strength Elongation at break 86.40 Mpa 70.07 Mpa 12 10 8 6 4 2 0 Elongation at break (%) CANF0.005 RCF CANF0.02 CANF0.01 CANF0.08 CANF0.04 Figure 8. Tensile properties histogram of composite fifillms.. The TG and DTG curves of RCF and CANF showed two rapidly weight loss stages (Figure 9a,b). The TG and DTG curves of RCF and CA0N.0F4 0.04 showed two rapidly weight loss stages (Figure At 118 ◦C–202 ◦C, the weight loss of RCF and CANF was probably due to the water release of 9a,b). At 118 °C–202 °C, the weight loss of RCF and CA0.0N4 F0.04 was probably due to the water release cellulose films. RCF and CANF were in hydrogel form, more bound water remained in the structure, of cellulose films. RCF and C0A.0N4 F0.04 were in hydrogel form, more bound water remained in the and a large amount of bound water evaporated in this stage which may cause a rapid weight loss. structure, and a large amount of bound water evaporated in this stage which may cause a rapid Differences in weight loss for RC and CANF in this range may due to the swelling ability which weight loss. Differences in weight loss for R0C.04and CANF0.04 in this range may due to the swelling could decrease because of Ag-NPs [42]. The weight loss in between 239 and 331 ◦C was mainly caused ability which could decrease because of Ag‐NPs [42]. The weight loss in between 239 and 331 °C was by fully combusting and pyrolyzing of cellulose. The mass loss rate difference between two films was mainly caused by fully combusting and pyrolyzing of cellulose. The mass loss rate difference between slight, but the DTG peak of CANF was smaller than RCF, which reflected the coupling Ag-NPs could two films was slight, but the D0T.0G4 peak of CANF0.04 was smaller than RCF, which reflected the improve the thermal stability of cellulose film. When the temperature reached to 750 ◦C, the residual coupling Ag‐NPs could improve the thermal stability of cellulose film. When the temperature weight of RCF was 0.32%, and the CANF was 2.77%. It can be determined that the main component reached to 750 °C, the residual weight0o.0f4 RCF was 0.32%, and the CANF0.04 was 2.77%. It can be of the extra residue was silver, which was stable at high temperature [43]. Based on calculated by determined that the main component of the extra residue was silver, which was stable at high Polymers 2020, 12, 440 11 of 15 the weight of the residual silver in CANF and the weight of silver added in CANF , the weight temperature [43]. Based on calculated by 0th.0e4 weight of the residual silver in CANF0.04 0a.n04d the weight ratio of the Ag-NPs successfully loaded in CANF was ~61%, indicating that most of the silver was oinfdsilcvaetirnagddtheadtinmCosAtNoFf 0t.0h4,ethseilvweerigwhatsrautitoiliozfetdh,e0w.0A4hgi‐cNhPwsasuscicneslsinfuellwyiltohadtheed i“nsuCsAtaNinFa0b.04lew”acso~n6c1e%pt, utilized, which was in line with the “sustainable” concept advocated by current research. advocated by current research. 118oC 202oC 239oC 331oC Water release Fiber combustion 100 80 60 40 20 0 (1) (2) (3) 10 8 6 2.77 4 0.32 2 0 750 (2) (4) (1) (3) 100 200 300 400 500 600 700 Temperature (oC) (4) Tmax oC (1) 184 (2) 182 (3) 298 (4) 294 Weight loss (%) 22.33 6.80 49.19 40.27 RCF CANF0.04 700 725 Weight loss (%) Derivative weight loss (%/oC) Tensile strength (MPa) RCF CANF0.04 100 200 300 400 500 600 700 Temperature (oC) (b) Figure 9. Thermal stability of composite films: (a) TG curves of RCF and CANF0.04 and (b) DTG curves (a) Figure 9. Thermal stability of composite films: (a) TG curves of RCF and CANF0.04 and (b) DTG curves of RCF and CANF0.04. of RCF and CANF0.04. 3.3. Analysis of Ag‐NPs and Films’ Antibacterial Activity The Ag‐NPs solution showed strong antibacterial properties. Based on the difference in OD600 values, the MIC values against E. coli and S. aureus were 32 μg/mL and 64 μg/mL, respectively, revealing that the solution has been able to inhibit bacterial growth and reproduction at lower concentrations. Studies have shown that the bactericidal mechanism of Ag‐NPs is mainly caused by silver clustering and anchoring to the negatively charged sites of bacterial cell wall, and thenPDF Image | One-Pot Synthesis of Antibacterial Silver Nanoparticle

PDF Search Title:

One-Pot Synthesis of Antibacterial Silver NanoparticleOriginal File Name Searched:

polymers-12-00440-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |