PDF Publication Title:

Text from PDF Page: 003

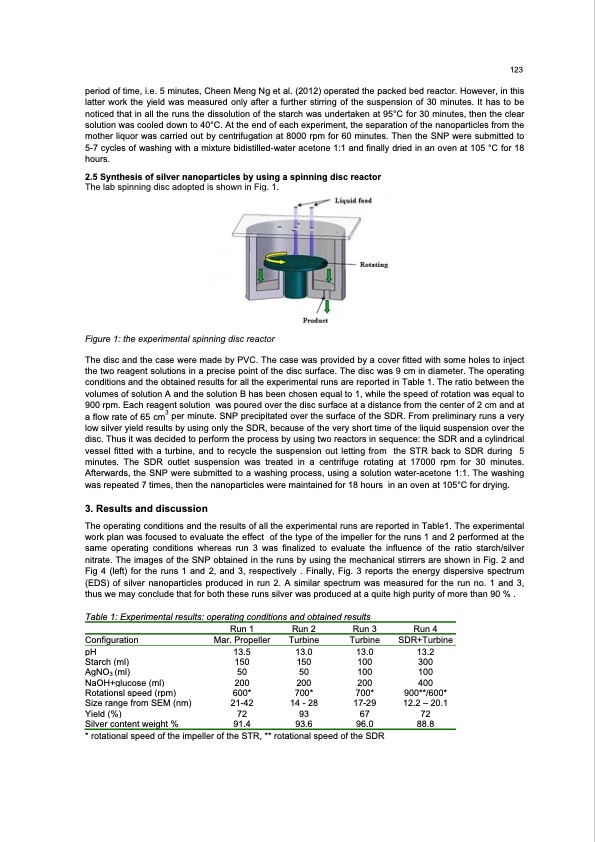

123 period of time, i.e. 5 minutes, Cheen Meng Ng et al. (2012) operated the packed bed reactor. However, in this latter work the yield was measured only after a further stirring of the suspension of 30 minutes. It has to be noticed that in all the runs the dissolution of the starch was undertaken at 95°C for 30 minutes, then the clear solution was cooled down to 40°C. At the end of each experiment, the separation of the nanoparticles from the mother liquor was carried out by centrifugation at 8000 rpm for 60 minutes. Then the SNP were submitted to 5-7 cycles of washing with a mixture bidistilled-water acetone 1:1 and finally dried in an oven at 105 °C for 18 hours. 2.5 Synthesis of silver nanoparticles by using a spinning disc reactor The lab spinning disc adopted is shown in Fig. 1. Figure 1: the experimental spinning disc reactor The disc and the case were made by PVC. The case was provided by a cover fitted with some holes to inject the two reagent solutions in a precise point of the disc surface. The disc was 9 cm in diameter. The operating conditions and the obtained results for all the experimental runs are reported in Table 1. The ratio between the volumes of solution A and the solution B has been chosen equal to 1, while the speed of rotation was equal to 900 rpm. Each reagent solution was poured over the disc surface at a distance from the center of 2 cm and at a flow rate of 65 cm3 per minute. SNP precipitated over the surface of the SDR. From preliminary runs a very low silver yield results by using only the SDR, because of the very short time of the liquid suspension over the disc. Thus it was decided to perform the process by using two reactors in sequence: the SDR and a cylindrical vessel fitted with a turbine, and to recycle the suspension out letting from the STR back to SDR during 5 minutes. The SDR outlet suspension was treated in a centrifuge rotating at 17000 rpm for 30 minutes. Afterwards, the SNP were submitted to a washing process, using a solution water-acetone 1:1. The washing was repeated 7 times, then the nanoparticles were maintained for 18 hours in an oven at 105°C for drying. 3. Results and discussion The operating conditions and the results of all the experimental runs are reported in Table1. The experimental work plan was focused to evaluate the effect of the type of the impeller for the runs 1 and 2 performed at the same operating conditions whereas run 3 was finalized to evaluate the influence of the ratio starch/silver nitrate. The images of the SNP obtained in the runs by using the mechanical stirrers are shown in Fig. 2 and Fig 4 (left) for the runs 1 and 2, and 3, respectively . Finally, Fig. 3 reports the energy dispersive spectrum (EDS) of silver nanoparticles produced in run 2. A similar spectrum was measured for the run no. 1 and 3, thus we may conclude that for both these runs silver was produced at a quite high purity of more than 90 % . Table 1: Experimental results: operating conditions and obtained results * rotational speed of the impeller of the STR, ** rotational speed of the SDR Run 1 Run 2 Run 3 Run 4 Configuration Mar. Propeller Turbine Turbine SDR+Turbine pH 13.5 13.0 13.0 13.2 Starch (ml) 150 150 100 300 AgNO3 (ml) 50 50 100 100 NaOH+glucose (ml) 200 200 200 400 Rotationsl speed (rpm) 600* 700* 700* 900**/600* Size range from SEM (nm) 21-42 14 - 28 17-29 12.2 – 20.1 Yield (%) 72 93 67 72 Silver content weight % 91.4 93.6 96.0 88.8PDF Image | Reactor Configuration on the Production of Silver Nanoparticles

PDF Search Title:

Reactor Configuration on the Production of Silver NanoparticlesOriginal File Name Searched:

sdr-silver-nano.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Infinity Turbine Developing Spinning Disc Reactor SDR or Spinning Disc Reactors reduce processing time for liquid production of Silver Nanoparticles.

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |