PDF Publication Title:

Text from PDF Page: 003

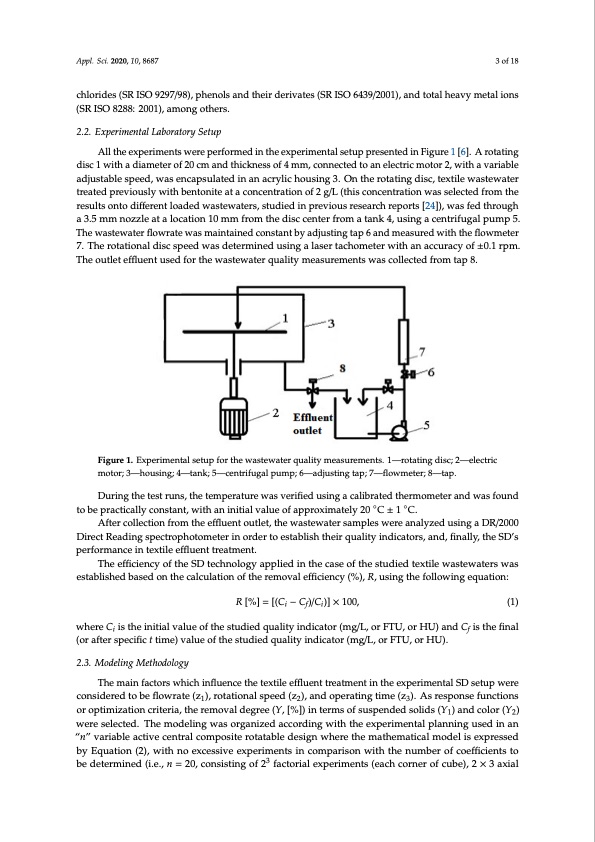

Appl. Sci. 2020, 10, x FOR PEER REVIEW 3 of 19 Appl. Sci. 2020, 10, 8687 3 of 18 chlorides (SR ISO 9297/98), phenols and their derivates (SR ISO 6439/2001), and total heavy metal ioncshl(oSrRidIeSsO(S8R28I8S:O2090219)7,/a9m8),opnhgeontohlesrasn.dtheirderivates(SRISO6439/2001),andtotalheavymetalions (SR ISO 8288: 2001), among others. 2.2. Experimental Laboratory Setup 2.2. Experimental Laboratory Setup All the experiments were performed in the experimental setup presented in Figure 1 [6]. A All the experiments were performed in the experimental setup presented in Figure 1 [6]. A rotating rotating disc 1 with a diameter of 20 cm and thickness of 4 mm, connected to an electric motor 2, with disc 1 with a diameter of 20 cm and thickness of 4 mm, connected to an electric motor 2, with a variable a variable adjustable speed, was encapsulated in an acrylic housing 3. On the rotating disc, textile adjustable speed, was encapsulated in an acrylic housing 3. On the rotating disc, textile wastewater wastewater treated previously with bentonite at a concentration of 2 g/L (this concentration was treated previously with bentonite at a concentration of 2 g/L (this concentration was selected from the selected from the results onto different loaded wastewaters, studied in previous research reports results onto different loaded wastewaters, studied in previous research reports [24]), was fed through [24]), was fed through a 3.5 mm nozzle at a location 10 mm from the disc center from a tank 4, using a 3.5 mm nozzle at a location 10 mm from the disc center from a tank 4, using a centrifugal pump 5. a centrifugal pump 5. The wastewater flowrate was maintained constant by adjusting tap 6 and The wastewater flowrate was maintained constant by adjusting tap 6 and measured with the flowmeter measured with the flowmeter 7. The rotational disc speed was determined using a laser tachometer 7. The rotational disc speed was determined using a laser tachometer with an accuracy of ±0.1 rpm. with an accuracy of ±0.1 rpm. The outlet effluent used for the wastewater quality measurements was The outlet effluent used for the wastewater quality measurements was collected from tap 8. collected from tap 8. Figure 1. Experimental setup for the wastewater quality measurements. 1—rotating disc; 2—electric Figure 1. Experimental setup for the wastewater quality measurements. 1—rotating disc; 2—electric momtort;o3r—;3h—ohuosiunsgin;4g—;4t—antakn;k5—;5c—encetrnifturigfuaglaplupmupm;p6—;6a—dajudsjutisntgintgapta;p7;—7—floflwomwemtert;e8r;—8—tapta.p. DuDruinrgingthtehetetsetstrurunnss,,tthe temperaturewaassvvereirfiifeidedusuinsignga calcibarliabtreadtethdetrhmeormeotmereatenrdawndaswfoausnd ◦◦ foutondbetoprbaectpircaclltyiccaollnysctaonts,twanith,wanithinaitniailnvitaialulevaolfuaepopfraopxpimroaxteimlya2te0lyC20±°1C±C1.°C. AfAtefrtecrolcloelclteicotniofnrofmromthetheeffeluffleunetnotuotluetl,etth, ethweawstaeswteawteartesramsapmlepslewsewreraenanlyazlyedzeudsuinsginagDaRD/2R0/02000 DiDreicrtecRteRadeaindginsgpsepctercotprohpohtomtoemterteinrionrdoerdretorteosteasbtalibshlisthethireqiruqauliatylitiyndinicdaitcoartso,rasn,dan,dfi,nfianllyal,ltyh,ethSeDS’Ds’s peprfeorrfmoramnacnecienitnextetixletileffelfflueunetnttretaretmatmenetn.t. ThTeheffeicffiiecniecnycoyfothf ethSeDSDtectehcnhonlogloygaypapplipeldieidnitnhethceacseasoefotfhtehsetustduieddietdextetixletilwe awstaeswteawteartserwsawsas esteasbtalibslhisehdebdabseadseodnotnhethcealccaulclautliaotnioonfothf ethremreomvoavlaelffeifficiecniecnyc(y%()%, R),,Ru,suinsigntghtehfeoflolollwowinigngeqeuqautaiotino:n: 2.3. Modeling Methodology 2.3. Modeling Methodology R [%] = [(Ci − Cf)/Ci)] × 100, (1) R [%] = [(Ci − Cf)/Ci)] × 100, (1) where Ci is the initial value of the studied quality indicator (mg/L, or FTU, or HU) and Cf is the final where Ci is the initial value of the studied quality indicator (mg/L, or FTU, or HU) and Cf is the final (or after specific t time) value of the studied quality indicator (mg/L, or FTU, or HU). (or after specific t time) value of the studied quality indicator (mg/L, or FTU, or HU). The main factors which influence the textile effluent treatment in the experimental SD setup The main factors which influence the textile effluent treatment in the experimental SD setup were were considered to be flowrate (z1), rotational speed (z2), and operating time (z3). As response considered to be flowrate (z1), rotational speed (z2), and operating time (z3). As response functions functions or optimization criteria, the removal degree (Y, [%]) in terms of suspended solids (Y1) and or optimization criteria, the removal degree (Y, [%]) in terms of suspended solids (Y1) and color (Y2) color (Y2) were selected. The modeling was organized according with the experimental planning used were selected. The modeling was organized according with the experimental planning used in an in an “n” variable active central composite rotatable design where the mathematical model is “n” variable active central composite rotatable design where the mathematical model is expressed expressed by Equation (2), with no excessive experiments in comparison with the number of by Equation (2), with no excessive experiments in comparison with the number of coefficients to coefficients to be determined (i.e., n = 20, consisting of 23 factorial experiments (each corner of cube), be determined (i.e., n = 20, consisting of 23 factorial experiments (each corner of cube), 2 × 3 axial 2 × 3 axial experiments (on axes, distance of ± α from center of rotation, α = ±1.682), k = 6 (experimentsPDF Image | Textile Wastewater Treatment on a Spinning Disc Reactor

PDF Search Title:

Textile Wastewater Treatment on a Spinning Disc ReactorOriginal File Name Searched:

applsci-10-08687.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |