PDF Publication Title:

Text from PDF Page: 002

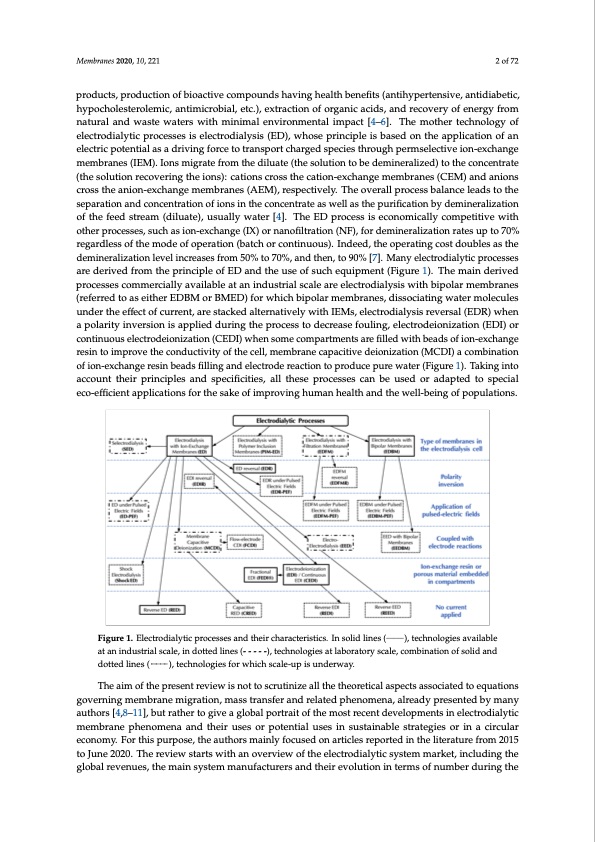

Membranes 2020, 10, 221 2 of 72 products, production of bioactive compounds having health benefits (antihypertensive, antidiabetic, hypocholesterolemic, antimicrobial, etc.), extraction of organic acids, and recovery of energy from natural and waste waters with minimal environmental impact [4–6]. The mother technology of electrodialytic processes is electrodialysis (ED), whose principle is based on the application of an electric potential as a driving force to transport charged species through permselective ion-exchange membranes (IEM). Ions migrate from the diluate (the solution to be demineralized) to the concentrate (the solution recovering the ions): cations cross the cation-exchange membranes (CEM) and anions Membranes 2020, 10, x FOR PEER REVIEW 2 of 72 cross the anion-exchange membranes (AEM), respectively. The overall process balance leads to the products, production of bioactive compounds having health benefits (antihypertensive, antidiabetic, separation and concentration of ions in the concentrate as well as the purification by demineralization hypocholesterolemic, antimicrobial, etc.), extraction of organic acids, and recovery of energy from naturalandwastewoaftetrhsewiftehemdinsitmraelaemnvi(rdonimlueantael),imupsaucta[l4l–y6].wTahteemro[t4h]e.rtTechenoEloDgypofrocessiseconomicallycompetitivewith electrodialytic processes is electrodialysis (ED), whose principle is based on the application of an other processes, such as ion-exchange (IX) or nanofiltration (NF), for demineralization rates up to 70% electric potential as a driving force to transport charged species through permselective ion-exchange regardless of the mode of operation (batch or continuous). Indeed, the operating cost doubles as the membranes (IEM). Ions migrate from the diluate (the solution to be demineralized) to the concentrate (thesolutionrecoverdinegmthienieornas)l:izcatitoinosncrloesvsetlheincactrieona-seexschfarnogmem5e0m%bratnoe7s0(C%EM,a)nadndtahneionn,sto90%[7].Manyelectrodialyticprocesses cross the anion-exchange membranes (AEM), respectively. The overall process balance leads to the are derived from the principle of ED and the use of such equipment (Figure 1). The main derived separation and concentration of ions in the concentrate as well as the purification by demineralization processes commercially available at an industrial scale are electrodialysis with bipolar membranes of the feed stream (diluate), usually water [4]. The ED process is economically competitive with other processes,suchasio(nr-efxechrranegdet(oIX)asoreniathnoefriltEraDtioBnM(NFo)r,fBorMdeEmDin)erfaolirzawtiohnicrahtebsiuppotloar70m%embranes,dissociatingwatermolecules regardless of the mode of operation (batch or continuous). Indeed, the operating cost doubles as the under the effect of current, are stacked alternatively with IEMs, electrodialysis reversal (EDR) when demineralization level increases from 50% to 70%, and then, to 90% [7]. Many electrodialytic a polarity inversion is applied during the process to decrease fouling, electrodeionization (EDI) or processes are derived from the principle of ED and the use of such equipment (Figure 1). The main derivedprocessescocmonmteirnciualolyusavealielacbtlreoadteainoninidzuastiroianls(cCalEeDarIe)welehcterondsiaolymsisewcoitmhpbiaprotlamrentsarefilledwithbeadsofion-exchange membranes (referred to as either EDBM or BMED) for which bipolar membranes, dissociating water resin to improve the conductivity of the cell, membrane capacitive deionization (MCDI) a combination molecules under the effect of current, are stacked alternatively with IEMs, electrodialysis reversal of ion-exchange resin beads filling and electrode reaction to produce pure water (Figure 1). Taking into (EDR) when a polarity inversion is applied during the process to decrease fouling, electrodeionization (aEDccI)oourncotntihneuiorusperleicntrcoidpelieonsizatniodn (sCpEeDcIi)fiwchietnieso,maelclomthpeasrtemepnrtsoacresses can be used or adapted to special filled with beads of ion-exchange resin to improve the conductivity of the cell, membrane capacitive eco-efficient applications for the sake of improving human health and the well-being of populations. deionization (MCDI) a combination of ion-exchange resin beads filling and electrode reaction to produce pure water (Figure 1). Taking into account their principles and specificities, all these processes can be used or adapted to special eco-efficient applications for the sake of improving human health and the well-being of populations Figure 1. Electrodialytic processes and their characteristics. In solid lines (_____), technologies available Figure 1. Electrodialytic processes and their characteristics. In solid lines (_____), technologies at an industrial scale, in dotted lines (- - - - -), technologies at laboratory scale, combination of solid and available at an industrial scale, in dotted lines (- - - - -), technologies at laboratory scale, combinationofsolidanddodttoettdedlilninees( ),technologiesforwhich,steccahlneo-ulopgiiesufonrderway. which scale-up is underway. The aim of the present review is not to scrutinize all the theoretical aspects associated to The aim of the present review is not to scrutinize all the theoretical aspects associated to equations equations governing membrane migration, mass transfer and related phenomena, already presented governing membrane migration, mass transfer and related phenomena, already presented by many by many authors [4,8–11], but rather to give a global portrait of the most recent developments in electrodialyticmembarauntehpohresno[4m,e8n–a1a1n]d,tbhueitrruasetshoerrptootegntiivaleuasesgilnosbuasltapinoarbtlerastirtatoefgitehseorminostrecentdevelopmentsinelectrodialytic membrane phenomena and their uses or potential uses in sustainable strategies or in a circular economy. For this purpose, the authors mainly focused on articles reported in the literature from 2015 to June 2020. The review starts with an overview of the electrodialytic system market, including the global revenues, the main system manufacturers and their evolution in terms of number during thePDF Image | Electrodialytic Processes

PDF Search Title:

Electrodialytic ProcessesOriginal File Name Searched:

membranes-10-00221.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |