PDF Publication Title:

Text from PDF Page: 003

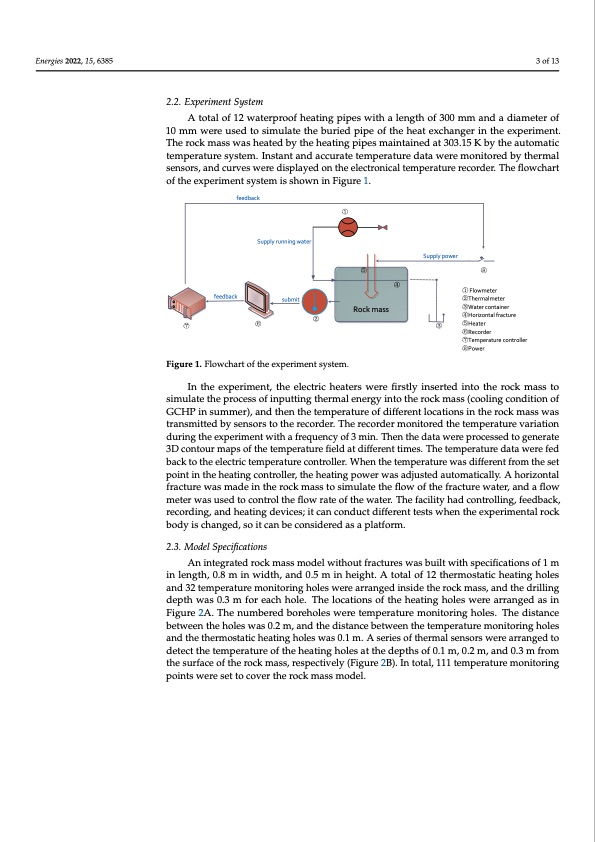

perature system. Instant and accurate temperature data were monitored by thermal c o s a e e c w n h s h i c h Energies 2022, 15, 6385 sors, and curves were displayed on the electronical temperature recorder. The flow of the experiment system is shown in Figure 1. In the experiment, the electric heaters were firstly inserted into the rock mass to ulate the process of inputting thermal energy into the rock mass (cooling conditi GCHP in summer), and then the temperature of different locations in t3hoef 1r3ock mas transmitted by sensors to the recorder. The recorder monitored the temperature vari during the experiment with a frequency of 3 min. Then the data were processed to g ate 3D contour maps of the temperature field at different times. The temperature 2.2. Experiment System were fed back to the electric temperature controller. When the temperature was diff A total of 12 waterproof heating pipes with a length of 300 mm and a diameter of from the set point in the heating controller, the heating power was adjusted automati 10 mm were used to simulate the buried pipe of the heat exchanger in the experiment. A horizontal fracture was made in the rock mass to simulate the flow of the fracture The rock mass was heated by the heating pipes maintained at 303.15 K by the automatic and a flow meter was used to control the flow rate of the water. The facility had co temperature system. Instant and accurate temperature data were monitored by thermal ling, feedback, recording, and heating devices; it can conduct different tests when t sensors, and curves were displayed on the electronical temperature recorder. The flowchart perimental rock body is changed, so it can be considered as a platform. of the experiment system is shown in Figure 1. feedback 1 Supply running water Supply power 8 5 4 Rock mass feedback submit 2 1 Flowmeter 2Thermalmeter 3Water container 4Horizontal fracture 7 6 3 5Heater 6Recorder 7Temperature controller 8Power Figure 1. Flowchart of the experiment system. Figure 1. Flowchart of the experiment system. In the experiment, the electric heaters were firstly inserted into the rock mass to 2.3. Model Specifications simulate the process of inputting thermal energy into the rock mass (cooling condition of An integrated rock mass model without fractures was built with specification GCHP in summer), and then the temperature of different locations in the rock mass was m in length, 0.8 m in width, and 0.5 m in height. A total of 12 thermostatic heating transmitted by sensors to the recorder. The recorder monitored the temperature variation and 32 temperature monitoring holes were arranged inside the rock mass, and the dr during the experiment with a frequency of 3 min. Then the data were processed to generate depth was 0.3 m for each hole. The locations of the heating holes were arranged 3D contour maps of the temperature field at different times. The temperature data were fed Figure 2A. The numbered boreholes were temperature monitoring holes. The distan back to the electric temperature controller. When the temperature was different from the set tween the holes was 0.2 m, and the distance between the temperature monitoring point in the heating controller, the heating power was adjusted automatically. A horizontal and the thermostatic heating holes was 0.1 m. A series of thermal sensors were arra fracture was made in the rock mass to simulate the flow of the fracture water, and a flow to detect the temperature of the heating holes at the depths of 0.1 m, 0.2 m, and 0.3 m meter was used to control the flow rate of the water. The facility had controlling, feedback, recording, and heating devices; it can conduct different tests when the experimental rock body is changed, so it can be considered as a platform. 2.3. Model Specifications An integrated rock mass model without fractures was built with specifications of 1 m in length, 0.8 m in width, and 0.5 m in height. A total of 12 thermostatic heating holes and 32 temperature monitoring holes were arranged inside the rock mass, and the drilling depth was 0.3 m for each hole. The locations of the heating holes were arranged as in Figure 2A. The numbered boreholes were temperature monitoring holes. The distance between the holes was 0.2 m, and the distance between the temperature monitoring holes and the thermostatic heating holes was 0.1 m. A series of thermal sensors were arranged to detect the temperature of the heating holes at the depths of 0.1 m, 0.2 m, and 0.3 m from the surface of the rock mass, respectively (Figure 2B). In total, 111 temperature monitoring points were set to cover the rock mass model.PDF Image | Research on the Application of Fracture Water

PDF Search Title:

Research on the Application of Fracture WaterOriginal File Name Searched:

energies-15-06385.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |