PDF Publication Title:

Text from PDF Page: 020

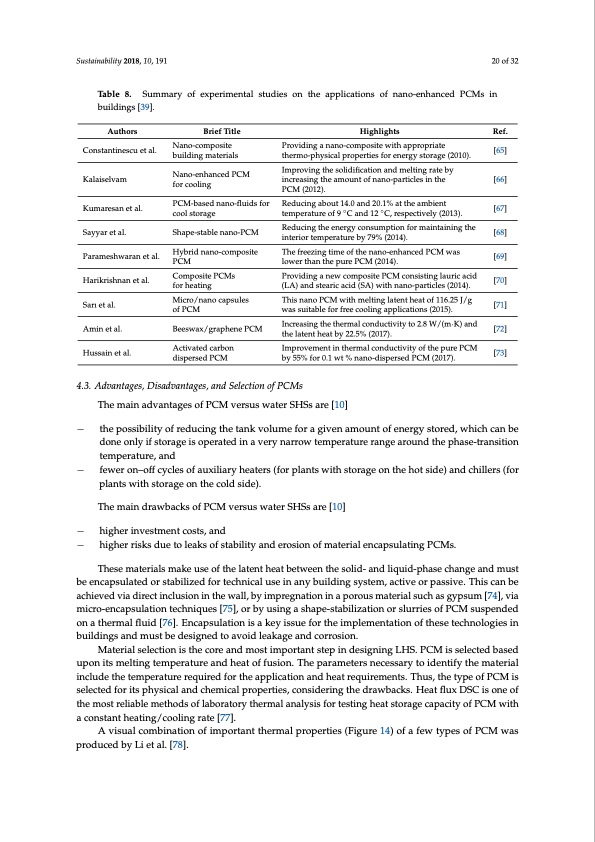

Sustainability 2018, 10, 191 20 of 32 Table 8. Summary of experimental studies on the applications of nano-enhanced PCMs in buildings [39]. Authors Constantinescu et al. Kalaiselvam Kumaresan et al. Sayyar et al. Parameshwaran et al. Harikrishnan et al. Sarı et al. Amin et al. Hussain et al. Brief Title Nano-composite building materials Nano-enhanced PCM for cooling PCM-based nano-fluids for cool storage Shape-stable nano-PCM Hybrid nano-composite PCM Composite PCMs for heating Micro/nano capsules of PCM Beeswax/graphene PCM Activated carbon dispersed PCM Highlights Ref. Providing a nano-composite with appropriate [65] thermo-physical properties for energy storage (2010). Improving the solidification and melting rate by increasing the amount of nano-particles in the [66] PCM (2012). Reducing about 14.0 and 20.1% at the ambient [67] temperature of 9 ◦C and 12 ◦C, respectively (2013). Reducing the energy consumption for maintaining the [68] interior temperature by 79% (2014). The freezing time of the nano-enhanced PCM was [69] lower than the pure PCM (2014). Providing a new composite PCM consisting lauric acid [70] (LA) and stearic acid (SA) with nano-particles (2014). This nano PCM with melting latent heat of 116.25 J/g [71] was suitable for free cooling applications (2015). Increasing the thermal conductivity to 2.8 W/(m·K) and [72] the latent heat by 22.5% (2017). Improvement in thermal conductivity of the pure PCM [73] by 55% for 0.1 wt % nano-dispersed PCM (2017). 4.3. Advantages, Disadvantages, and Selection of PCMs − − − − The main advantages of PCM versus water SHSs are [10] the possibility of reducing the tank volume for a given amount of energy stored, which can be done only if storage is operated in a very narrow temperature range around the phase-transition temperature, and fewer on–off cycles of auxiliary heaters (for plants with storage on the hot side) and chillers (for plants with storage on the cold side). The main drawbacks of PCM versus water SHSs are [10] higher investment costs, and higher risks due to leaks of stability and erosion of material encapsulating PCMs. These materials make use of the latent heat between the solid- and liquid-phase change and must be encapsulated or stabilized for technical use in any building system, active or passive. This can be achieved via direct inclusion in the wall, by impregnation in a porous material such as gypsum [74], via micro-encapsulation techniques [75], or by using a shape-stabilization or slurries of PCM suspended on a thermal fluid [76]. Encapsulation is a key issue for the implementation of these technologies in buildings and must be designed to avoid leakage and corrosion. Material selection is the core and most important step in designing LHS. PCM is selected based upon its melting temperature and heat of fusion. The parameters necessary to identify the material include the temperature required for the application and heat requirements. Thus, the type of PCM is selected for its physical and chemical properties, considering the drawbacks. Heat flux DSC is one of the most reliable methods of laboratory thermal analysis for testing heat storage capacity of PCM with a constant heating/cooling rate [77]. A visual combination of important thermal properties (Figure 14) of a few types of PCM was produced by Li et al. [78].PDF Image | Comprehensive Review of Thermal Energy Storage

PDF Search Title:

Comprehensive Review of Thermal Energy StorageOriginal File Name Searched:

a554bca3a326b394928e3ab67fdd8d40c756.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |