PDF Publication Title:

Text from PDF Page: 003

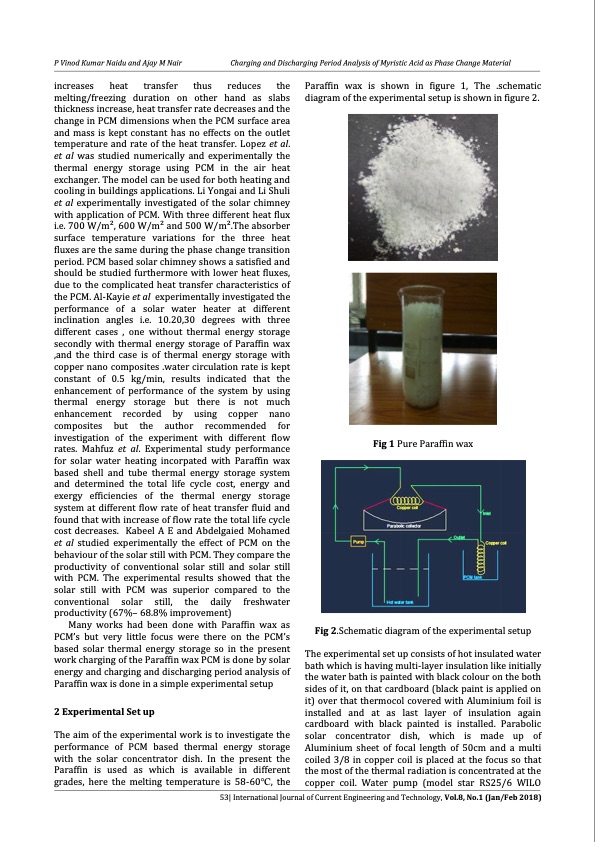

P Vinod Kumar Naidu and Ajay M Nair Charging and Discharging Period Analysis of Myristic Acid as Phase Change Material increases heat transfer thus reduces the melting/freezing duration on other hand as slabs thickness increase, heat transfer rate decreases and the change in PCM dimensions when the PCM surface area and mass is kept constant has no effects on the outlet temperature and rate of the heat transfer. Lopez et al. et al was studied numerically and experimentally the thermal energy storage using PCM in the air heat exchanger. The model can be used for both heating and cooling in buildings applications. Li Yongai and Li Shuli et al experimentally investigated of the solar chimney with application of PCM. With three different heat flux i.e. 700 W/m2, 600 W/m2 and 500 W/m2.The absorber surface temperature variations for the three heat fluxes are the same during the phase change transition period. PCM based solar chimney shows a satisfied and should be studied furthermore with lower heat fluxes, due to the complicated heat transfer characteristics of the PCM. Al-Kayie et al experimentally investigated the performance of a solar water heater at different inclination angles i.e. 10.20,30 degrees with three different cases , one without thermal energy storage secondly with thermal energy storage of Paraffin wax ,and the third case is of thermal energy storage with copper nano composites .water circulation rate is kept constant of 0.5 kg/min, results indicated that the enhancement of performance of the system by using thermal energy storage but there is not much enhancement recorded by using copper nano composites but the author recommended for investigation of the experiment with different flow rates. Mahfuz et al. Experimental study performance for solar water heating incorpated with Paraffin wax based shell and tube thermal energy storage system and determined the total life cycle cost, energy and exergy efficiencies of the thermal energy storage system at different flow rate of heat transfer fluid and found that with increase of flow rate the total life cycle cost decreases. Kabeel A E and Abdelgaied Mohamed et al studied experimentally the effect of PCM on the behaviour of the solar still with PCM. They compare the productivity of conventional solar still and solar still with PCM. The experimental results showed that the solar still with PCM was superior compared to the conventional solar still, the daily freshwater productivity (67%– 68.8% improvement) Many works had been done with Paraffin wax as PCM’s but very little focus were there on the PCM’s based solar thermal energy storage so in the present work charging of the Paraffin wax PCM is done by solar energy and charging and discharging period analysis of Paraffin wax is done in a simple experimental setup 2 Experimental Set up The aim of the experimental work is to investigate the performance of PCM based thermal energy storage with the solar concentrator dish. In the present the Paraffin is used as which is available in different grades, here the melting temperature is 58-60°C, the Paraffin wax is shown in figure 1, The .schematic diagram of the experimental setup is shown in figure 2. Fig 1 Pure Paraffin wax Fig 2.Schematic diagram of the experimental setup The experimental set up consists of hot insulated water bath which is having multi-layer insulation like initially the water bath is painted with black colour on the both sides of it, on that cardboard (black paint is applied on it) over that thermocol covered with Aluminium foil is installed and at as last layer of insulation again cardboard with black painted is installed. Parabolic solar concentrator dish, which is made up of Aluminium sheet of focal length of 50cm and a multi coiled 3/8 in copper coil is placed at the focus so that the most of the thermal radiation is concentrated at the copper coil. Water pump (model star RS25/6 WILO 53| International Journal of Current Engineering and Technology, Vol.8, No.1 (Jan/Feb 2018)PDF Image | Analysis of Paraffin Wax as a Phase Change Material

PDF Search Title:

Analysis of Paraffin Wax as a Phase Change MaterialOriginal File Name Searched:

Analysis_of_Paraffin_Wax_as_a_Phase_Change_Materia.pdfDIY PDF Search: Google It | Yahoo | Bing

Turbine and System Plans CAD CAM: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. More Info

Waste Heat Power Technology: Organic Rankine Cycle uses waste heat to make electricity, shaft horsepower and cooling. More Info

All Turbine and System Products: Infinity Turbine ORD systems, turbine generator sets, build plans and more to use your waste heat from 30C to 100C. More Info

CO2 Phase Change Demonstrator: CO2 goes supercritical at 30 C. This is a experimental platform which you can use to demonstrate phase change with low heat. Includes integration area for small CO2 turbine, static generator, and more. This can also be used for a GTL Gas to Liquids experimental platform. More Info

Introducing the Infinity Turbine Products Infinity Turbine develops and builds systems for making power from waste heat. It also is working on innovative strategies for storing, making, and deploying energy. More Info

Need Strategy? Use our Consulting and analyst services Infinity Turbine LLC is pleased to announce its consulting and analyst services. We have worked in the renewable energy industry as a researcher, developing sales and markets, along with may inventions and innovations. More Info

Made in USA with Global Energy Millennial Web Engine These pages were made with the Global Energy Web PDF Engine using Filemaker (Claris) software.

Sand Battery Sand and Paraffin for TES Thermo Energy Storage More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |