PDF Publication Title:

Text from PDF Page: 043

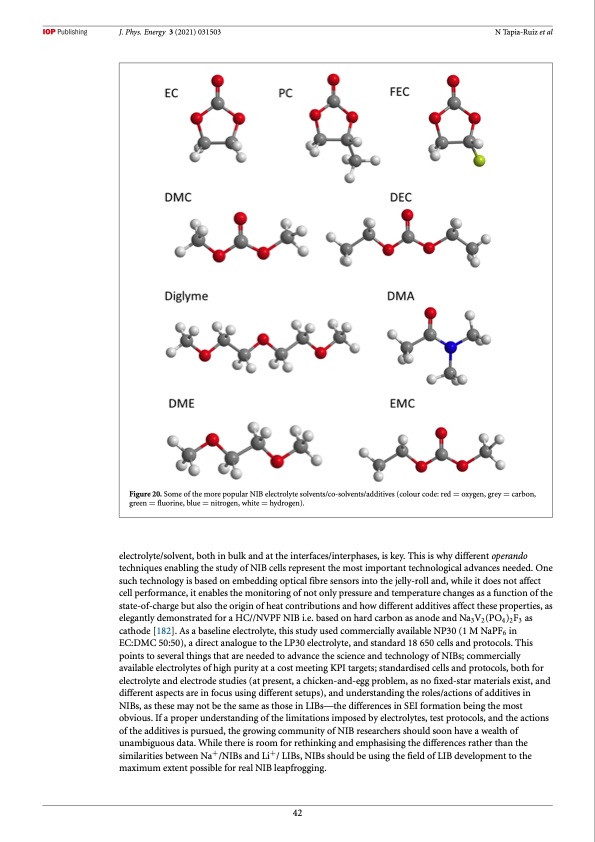

J. Phys. Energy 3 (2021) 031503 N Tapia-Ruiz et al Figure 20. Some of the more popular NIB electrolyte solvents/co-solvents/additives (colour code: red = oxygen, grey = carbon, green = fluorine, blue = nitrogen, white = hydrogen). electrolyte/solvent, both in bulk and at the interfaces/interphases, is key. This is why different operando techniques enabling the study of NIB cells represent the most important technological advances needed. One such technology is based on embedding optical fibre sensors into the jelly-roll and, while it does not affect cell performance, it enables the monitoring of not only pressure and temperature changes as a function of the state-of-charge but also the origin of heat contributions and how different additives affect these properties, as elegantly demonstrated for a HC//NVPF NIB i.e. based on hard carbon as anode and Na3V2(PO4)2F3 as cathode [182]. As a baseline electrolyte, this study used commercially available NP30 (1 M NaPF6 in EC:DMC 50:50), a direct analogue to the LP30 electrolyte, and standard 18 650 cells and protocols. This points to several things that are needed to advance the science and technology of NIBs; commercially available electrolytes of high purity at a cost meeting KPI targets; standardised cells and protocols, both for electrolyte and electrode studies (at present, a chicken-and-egg problem, as no fixed-star materials exist, and different aspects are in focus using different setups), and understanding the roles/actions of additives in NIBs, as these may not be the same as those in LIBs—the differences in SEI formation being the most obvious. If a proper understanding of the limitations imposed by electrolytes, test protocols, and the actions of the additives is pursued, the growing community of NIB researchers should soon have a wealth of unambiguous data. While there is room for rethinking and emphasising the differences rather than the similarities between Na+/NIBs and Li+/ LIBs, NIBs should be using the field of LIB development to the maximum extent possible for real NIB leapfrogging. 42PDF Image | roadmap for sodium-ion batteries

PDF Search Title:

roadmap for sodium-ion batteriesOriginal File Name Searched:

sodium-ion-batteries.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |