PDF Publication Title:

Text from PDF Page: 024

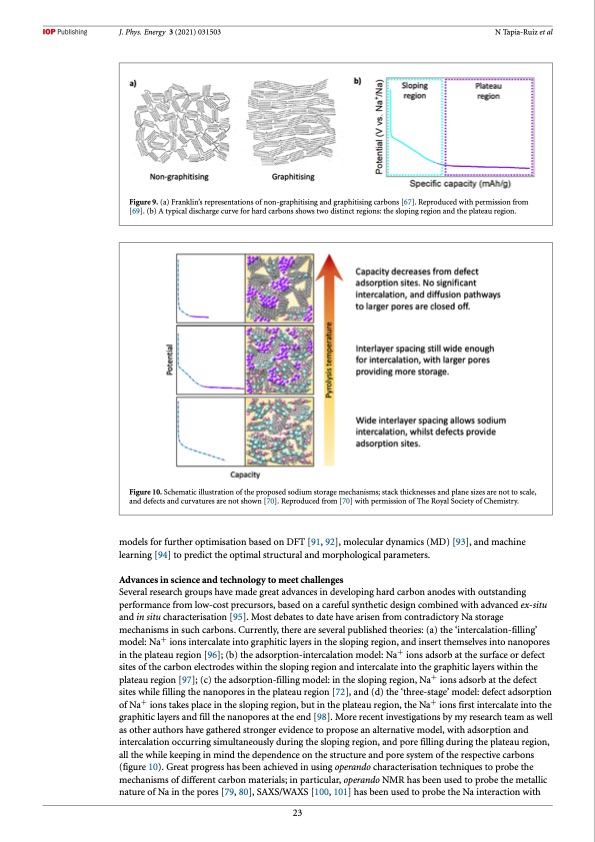

J. Phys. Energy 3 (2021) 031503 N Tapia-Ruiz et al Figure 9. (a) Franklin’s representations of non-graphitising and graphitising carbons [67]. Reproduced with permission from [69]. (b) A typical discharge curve for hard carbons shows two distinct regions: the sloping region and the plateau region. Figure 10. Schematic illustration of the proposed sodium storage mechanisms; stack thicknesses and plane sizes are not to scale, and defects and curvatures are not shown [70]. Reproduced from [70] with permission of The Royal Society of Chemistry. models for further optimisation based on DFT [91, 92], molecular dynamics (MD) [93], and machine learning [94] to predict the optimal structural and morphological parameters. Advances in science and technology to meet challenges Several research groups have made great advances in developing hard carbon anodes with outstanding performance from low-cost precursors, based on a careful synthetic design combined with advanced ex-situ and in situ characterisation [95]. Most debates to date have arisen from contradictory Na storage mechanisms in such carbons. Currently, there are several published theories: (a) the ‘intercalation-filling’ model: Na+ ions intercalate into graphitic layers in the sloping region, and insert themselves into nanopores in the plateau region [96]; (b) the adsorption-intercalation model: Na+ ions adsorb at the surface or defect sites of the carbon electrodes within the sloping region and intercalate into the graphitic layers within the plateau region [97]; (c) the adsorption-filling model: in the sloping region, Na+ ions adsorb at the defect sites while filling the nanopores in the plateau region [72], and (d) the ‘three-stage’ model: defect adsorption of Na+ ions takes place in the sloping region, but in the plateau region, the Na+ ions first intercalate into the graphitic layers and fill the nanopores at the end [98]. More recent investigations by my research team as well as other authors have gathered stronger evidence to propose an alternative model, with adsorption and intercalation occurring simultaneously during the sloping region, and pore filling during the plateau region, all the while keeping in mind the dependence on the structure and pore system of the respective carbons (figure 10). Great progress has been achieved in using operando characterisation techniques to probe the mechanisms of different carbon materials; in particular, operando NMR has been used to probe the metallic nature of Na in the pores [79, 80], SAXS/WAXS [100, 101] has been used to probe the Na interaction with 23PDF Image | roadmap for sodium-ion batteries

PDF Search Title:

roadmap for sodium-ion batteriesOriginal File Name Searched:

sodium-ion-batteries.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |