PDF Publication Title:

Text from PDF Page: 007

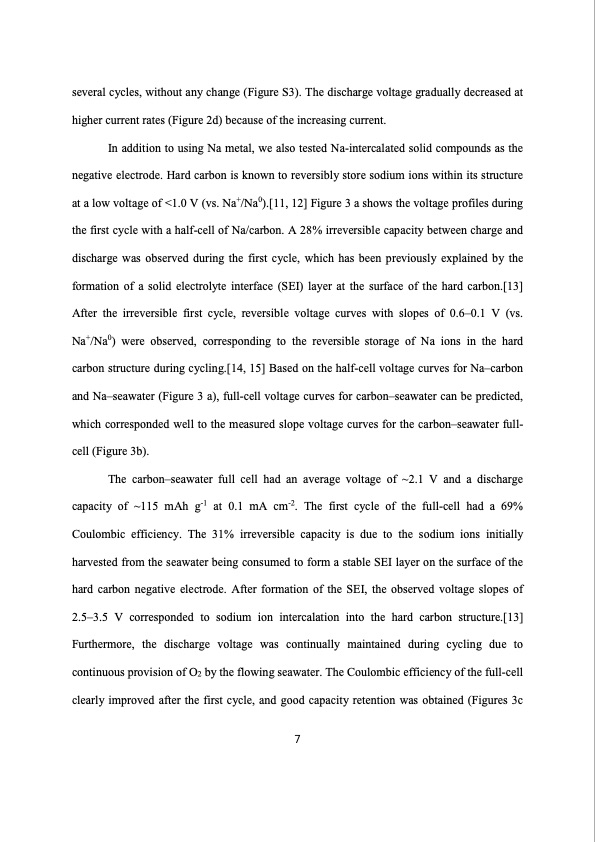

several cycles, without any change (Figure S3). The discharge voltage gradually decreased at higher current rates (Figure 2d) because of the increasing current. In addition to using Na metal, we also tested Na-intercalated solid compounds as the negative electrode. Hard carbon is known to reversibly store sodium ions within its structure at a low voltage of <1.0 V (vs. Na+/Na0).[11, 12] Figure 3 a shows the voltage profiles during the first cycle with a half-cell of Na/carbon. A 28% irreversible capacity between charge and discharge was observed during the first cycle, which has been previously explained by the formation of a solid electrolyte interface (SEI) layer at the surface of the hard carbon.[13] After the irreversible first cycle, reversible voltage curves with slopes of 0.6–0.1 V (vs. Na+/Na0) were observed, corresponding to the reversible storage of Na ions in the hard carbon structure during cycling.[14, 15] Based on the half-cell voltage curves for Na–carbon and Na–seawater (Figure 3 a), full-cell voltage curves for carbon–seawater can be predicted, which corresponded well to the measured slope voltage curves for the carbon–seawater full- cell (Figure 3b). The carbon–seawater full cell had an average voltage of ~2.1 V and a discharge capacity of ~115 mAh g-1 at 0.1 mA cm-2. The first cycle of the full-cell had a 69% Coulombic efficiency. The 31% irreversible capacity is due to the sodium ions initially harvested from the seawater being consumed to form a stable SEI layer on the surface of the hard carbon negative electrode. After formation of the SEI, the observed voltage slopes of 2.5–3.5 V corresponded to sodium ion intercalation into the hard carbon structure.[13] Furthermore, the discharge voltage was continually maintained during cycling due to continuous provision of O2 by the flowing seawater. The Coulombic efficiency of the full-cell clearly improved after the first cycle, and good capacity retention was obtained (Figures 3c 7PDF Image | Rechargeable Seawater Battery

PDF Search Title:

Rechargeable Seawater BatteryOriginal File Name Searched:

1337148.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |