PDF Publication Title:

Text from PDF Page: 005

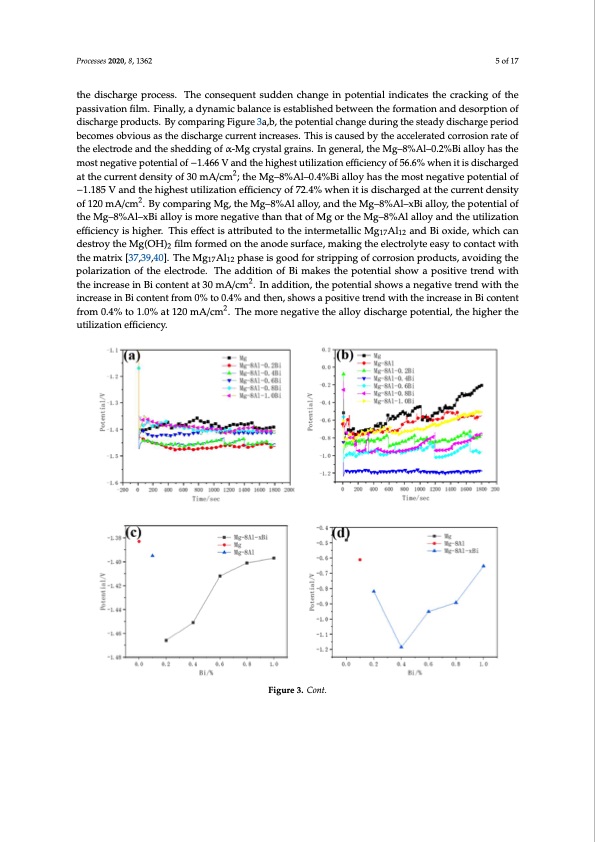

Processes 2020, 8, 1362 5 of 17 Processes 2020, 8, x FOR PEER REVIEW 5 of 17 the discharge process. The consequent sudden change in potential indicates the cracking of the passivation film. Finally, a dynamic balance is established between the formation and desorption of the passivation film. Finally, a dynamic balance is established between the formation and desorption discohfadrigsechparrogdeupcrtos.dBuyctsc.oBmypcaorminpgaFringgurFeig3ua,rbe,3tha,ebp, tohtenptoiatelnchtianl cgheadnugreindgurthinegstheaedsytedadisychdairsgcheapregreiod becpoemrieosdobveicoumseassothbevidoiusschaasrgtehecudrirsecnhtairngcerecausrerse.nTthiinscirseacsaeuss.eTdhbisytihsecauccselderabtyedthceorarcocseiloenrartaetdeof theceolrercotsriodnerantedotfhtehseheldecdtirnogdeofanαd-Mthgecsrhyesdtadlinggraoinfsα.-IMnggecrnyesrtal,gthraeinMs.gI–n8%geAnel–ra0l.,2%thBeiMalglo–8y%hAasl–the 0.2%Bi alloy has the most negative potential of −1.466 V and the highest utilization efficiency of 56.6% most negative potential of −1.466 V and the highest utilization efficiency of 56.6% when it is discharged when it is discharged at the curren2t density of 30 mA/cm2; the Mg–8%Al–0.4%Bi alloy has the most at the current density of 30 mA/cm ; the Mg–8%Al–0.4%Bi alloy has the most negative potential of negative potential of −1.185 V and the highest utilization efficiency of 72.4% when it is discharged at −1.185 V and the highest utilization efficiency of 72.4% when it is discharged at the current density the current2density of 120 mA/cm2. By comparing Mg, the Mg–8%Al alloy, and the Mg–8%Al–xBi of 120 mA/cm . By comparing Mg, the Mg–8%Al alloy, and the Mg–8%Al–xBi alloy, the potential of alloy, the potential of the Mg–8%Al–xBi alloy is more negative than that of Mg or the Mg–8%Al alloy the Mg–8%Al–xBi alloy is more negative than that of Mg or the Mg–8%Al alloy and the utilization and the utilization efficiency is higher. This effect is attributed to the intermetallic Mg17Al12 and Bi efficiency is higher. This effect is attributed to the intermetallic Mg17Al12 and Bi oxide, which can oxide, which can destroy the Mg(OH)2 film formed on the anode surface, making the electrolyte easy destroytheMg(OH) filmformedontheanodesurface,makingtheelectrolyteeasytocontactwith 2 to contact with the matrix [37,39,40]. The Mg17Al12 phase is good for stripping of corrosion products, the matrix [37,39,40]. The Mg Al phase is good for stripping of corrosion products, avoiding the 17 12 avoiding the polarization of the electrode. The addition of Bi makes the potential show a positive polarization of the electrode. The addition of Bi makes the potential show a positive trend with trend with the increase in Bi content at 30 mA/cm2. In addition, the potential shows a negative trend the increase in Bi content at 30 mA/cm2. In addition, the potential shows a negative trend with the with the increase in Bi content from 0% to 0.4% and then, shows a positive trend with the increase in increase in Bi content from 0% to 0.4% and the2n, shows a positive trend with the increase in Bi content Bi content from 0.4% to 1.0% at 120 mA/cm . The more negative the alloy discharge potential, the from 0.4% to 1.0% at 120 mA/cm . The more negative the alloy discharge potential, the higher the higher the utilization efficiency.2 utilization efficiency. Figure 3. Cont.PDF Image | Alloy Anode for Seawater Batteries and Related Mechanisms

PDF Search Title:

Alloy Anode for Seawater Batteries and Related MechanismsOriginal File Name Searched:

processes-08-01362.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |