PDF Publication Title:

Text from PDF Page: 002

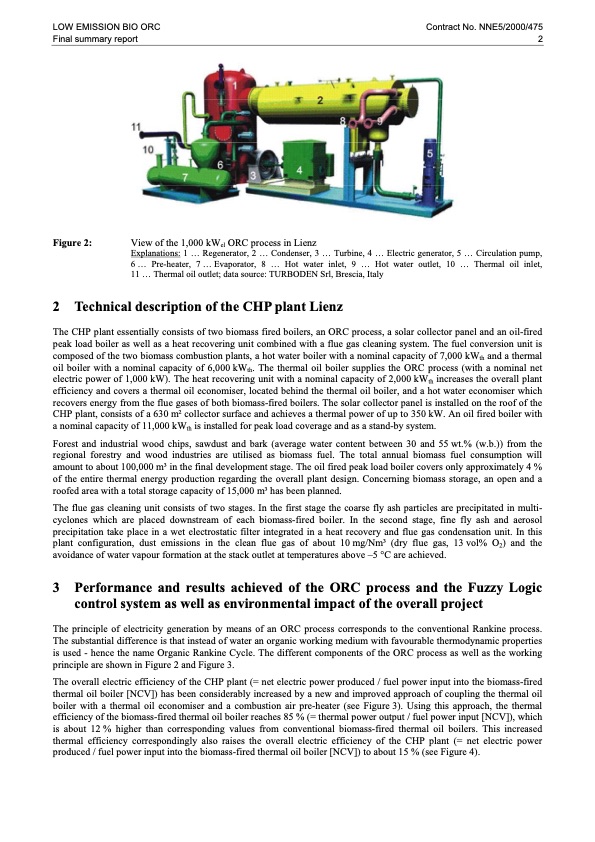

LOW EMISSION BIO ORC Contract No. NNE5/2000/475 Final summary report 2 Figure 2: View of the 1,000 kWel ORC process in Lienz Explanations: 1 ... Regenerator, 2 ... Condenser, 3 ... Turbine, 4 ... Electric generator, 5 ... Circulation pump, 6 ... Pre-heater, 7 ... Evaporator, 8 ... Hot water inlet, 9 ... Hot water outlet, 10 ... Thermal oil inlet, 11 ... Thermal oil outlet; data source: TURBODEN Srl, Brescia, Italy 2 Technical description of the CHP plant Lienz The CHP plant essentially consists of two biomass fired boilers, an ORC process, a solar collector panel and an oil-fired peak load boiler as well as a heat recovering unit combined with a flue gas cleaning system. The fuel conversion unit is composed of the two biomass combustion plants, a hot water boiler with a nominal capacity of 7,000 kWth and a thermal oil boiler with a nominal capacity of 6,000 kWth. The thermal oil boiler supplies the ORC process (with a nominal net electric power of 1,000 kW). The heat recovering unit with a nominal capacity of 2,000 kWth increases the overall plant efficiency and covers a thermal oil economiser, located behind the thermal oil boiler, and a hot water economiser which recovers energy from the flue gases of both biomass-fired boilers. The solar collector panel is installed on the roof of the CHP plant, consists of a 630 m2 collector surface and achieves a thermal power of up to 350 kW. An oil fired boiler with a nominal capacity of 11,000 kWth is installed for peak load coverage and as a stand-by system. Forest and industrial wood chips, sawdust and bark (average water content between 30 and 55 wt.% (w.b.)) from the regional forestry and wood industries are utilised as biomass fuel. The total annual biomass fuel consumption will amount to about 100,000 m3 in the final development stage. The oil fired peak load boiler covers only approximately 4 % of the entire thermal energy production regarding the overall plant design. Concerning biomass storage, an open and a roofed area with a total storage capacity of 15,000 m3 has been planned. The flue gas cleaning unit consists of two stages. In the first stage the coarse fly ash particles are precipitated in multi- cyclones which are placed downstream of each biomass-fired boiler. In the second stage, fine fly ash and aerosol precipitation take place in a wet electrostatic filter integrated in a heat recovery and flue gas condensation unit. In this plant configuration, dust emissions in the clean flue gas of about 10 mg/Nm3 (dry flue gas, 13 vol% O2) and the avoidance of water vapour formation at the stack outlet at temperatures above –5 °C are achieved. 3 Performance and results achieved of the ORC process and the Fuzzy Logic control system as well as environmental impact of the overall project The principle of electricity generation by means of an ORC process corresponds to the conventional Rankine process. The substantial difference is that instead of water an organic working medium with favourable thermodynamic properties is used - hence the name Organic Rankine Cycle. The different components of the ORC process as well as the working principle are shown in Figure 2 and Figure 3. The overall electric efficiency of the CHP plant (= net electric power produced / fuel power input into the biomass-fired thermal oil boiler [NCV]) has been considerably increased by a new and improved approach of coupling the thermal oil boiler with a thermal oil economiser and a combustion air pre-heater (see Figure 3). Using this approach, the thermal efficiency of the biomass-fired thermal oil boiler reaches 85 % (= thermal power output / fuel power input [NCV]), which is about 12 % higher than corresponding values from conventional biomass-fired thermal oil boilers. This increased thermal efficiency correspondingly also raises the overall electric efficiency of the CHP plant (= net electric power produced / fuel power input into the biomass-fired thermal oil boiler [NCV]) to about 15 % (see Figure 4).PDF Image | FUZZY LOGIC CONTROLLED CHP PLANT FOR BIOMASS FUELS

PDF Search Title:

FUZZY LOGIC CONTROLLED CHP PLANT FOR BIOMASS FUELSOriginal File Name Searched:

nne5_475_2000.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |