PDF Publication Title:

Text from PDF Page: 008

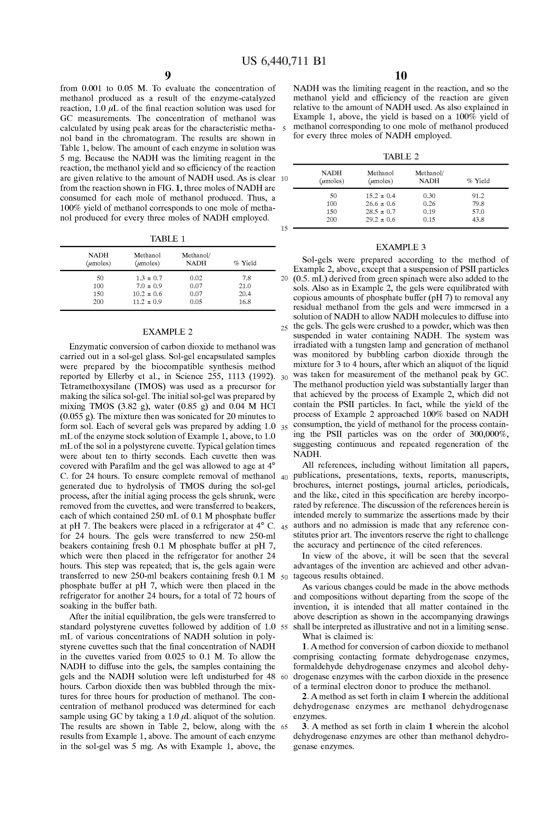

NADH (umoles) 50 100 150 200 Methanol (umoles) 1.3 1 0.7 7.0 1 0.9 10.2 1 0.6 11.2 1 0.9 Methanol/ NADH % Yield 0.02 7.8 0.07 21.0 0.07 20.4 0.05 16.8 Sol-gels Were prepared according Example 2, above, except that a suspension of PSII particles US 6,440,711B1 9 10 from 0.001 to 0.05 M. To evaluate the concentration of methanol produced as a result of the enZyme-catalyZed reaction, 1.0 pL of the ?nal reaction solution Was used for GC measurements. The concentration of methanol Was calculated by using peak areas for the characteristic metha nol band in the chromatogram. The results are shoWn in Table 1, beloW. The amount of each enZyme in solution Was 5mg.BecausetheNADH Wasthelimitingreagentinthe reaction,themethanolyieldandsoefficiencyofthereaction aregivenrelativetotheamountofNADH used.Asisclear fromthereactionshoWninFIG.1,threemolesofNADH are consumed for each mole of methanol produced. Thus, a 100% yield of methanol corresponds to one mole of metha nolproducedforeverythreemolesofNADH employed. NADH Wasthelimitingreagentinthereaction,andsothe methanol yield and efficiency of the reaction are given relativetotheamountofNADH used.Asalsoexplainedin Example 1, above, the yield is based on a 100% yield of methanol corresponding to one mole of methanol produced foreverythreemolesofNADH employed. TABLE 1 EXAMPLE 2 20 (0.5.mL)derivedfromgreenspinachWerealsoaddedtothe sols. Also as in Example 2, the gels Were equilibrated With copious amounts of phosphate buffer (pH 7) to removal any residual methanol from the gels and Were immersed in a solutionofNADH toalloWNADH moleculestodiffuseinto 25 thegels.ThegelsWerecrushedtoapoWder,WhichWasthen suspended in Water containing NADH. The system Was irradiated With a tungsten lamp and generation of methanol Was monitored by bubbling carbon dioxide through the mixture for 3 to 4 hours, after Which an aliquot of the liquid 10 15 NADH (umoles) 50 100 150 200 Methanol (umoles) 15.2 1 0.4 26.6 1 0.6 28.5 1 0.7 29.2 1 0.6 Methanol/ NADH % Yield 0.30 91.2 0.26 79.8 0.19 57.0 0.15 43.8 EnZymatic conversion of carbon dioxide to methanol Was carried out in a sol-gel glass. Sol-gel encapsulated samples Were prepared by the biocompatible synthesis method reportedbyEllerbyetal.,inScience255,1113(1992).30 WastakenformeasurementofthemethanolpeakbyGC. Tetramethoxysilane (TMOS) Was used as a precursor for makingthesilicasol-gel.Theinitialsol-gelWaspreparedby mixingTMOS (3.82g),Water(0.85g)and0.04M HCl (0.055 g). The mixture then Was sonicated for 20 minutes to formsol.EachofseveralgelsWaspreparedbyadding1.035 consumption,theyieldofmethanolfortheprocesscontain mL oftheenZyme stocksolutionofExample 1,above,to1.0 mL ofthesolinapolystyrenecuvette.Typicalgelationtimes Were about ten to thirty seconds. Each cuvette then Was covered With Para?lm and the gel Was alloWed to age at 4° C. for 24 hours. To ensure complete removal of methanol generatedduetohydrolysisofTMOS duringthesol-gel process, after the initial aging process the gels shrunk, Were removed from the cuvettes, and Were transferred to beakers, eachofWhichcontained250mLof0.1M phosphatebuffer atpH7.ThebeakersWereplacedinarefrigeratorat4°C.45 authorsandnoadmissionismadethatanyreferencecon for 24 hours. The gels Were transferred to neW 250-ml beakerscontainingfresh0.1M phosphatebufferatpH7, Which Were then placed in the refrigerator for another 24 hours. This step Was repeated; that is, the gels again Were transferredtoneW250-mlbeakerscontainingfresh0.1M phosphate buffer at pH 7, Which Were then placed in the refrigerator for another 24 hours, for a total of 72 hours of soaking in the buffer bath. stitutespriorart.Theinventorsreservetherighttochallenge theaccuracyandpertinenceofthecitedreferences. In vieW of the above, it Will be seen that the several advantages of the invention are achieved and other advan 50 tageousresultsobtained. As various changes could be made in the above methods and compositions Without departing from the scope of the invention, it is intended that all matter contained in the above description as shoWn in the accompanying draWings TABLE 2 EXAMPLE 3 The methanol production yield Was substantially larger than that achieved by the process of Example 2, Which did not contain the PSII particles. In fact, While the yield of the process of Example 2 approached 100% based on NADH ing the PSII particles Was on the order of 300,000%, suggesting continuous and repeated regeneration of the NADH. All references, including Without limitation al papers, 40 publications, presentations, texts, reports, manuscripts, brochures,internetpostings,journalarticles,periodicals, After the initial equilibration, the gels Were transferred to standardpolystyrenecuvettesfolloWedbyadditionof1.055 shallbeinterpretedasillustrativeandnotinalimitingsense. mL ofvariousconcentrationsofNADH solutioninpoly styrenecuvettessuchthatthe?nalconcentrationofNADH in the cuvettes varied from 0.025 to 0.1 M. To alloW the NADH todiffuseintothegels,thesamplescontainingthe gelsandtheNADH solutionWereleftundisturbedfor48 hours. Carbon dioxide then Was bubbled through the mix tures for three hours for production of methanol. The con centration of methanol produced Was determined for each sampleusingGC bytakinga1.0pLaliquotofthesolution. The results are shoWn in Table 2, beloW, along With the results from Example 1, above. The amount of each enZyme in the sol-gel Was 5 mg. As With Example 1, above, the Whatisclaimedis: 1.Amethod forconversionofcarbondioxidetomethanol comprising contacting formate dehydrogenase enZymes, formaldehyde dehydrogenase enZymes and alcohol dehy 60 drogenaseenZymesWiththecarbondioxideinthepresence of a terminal electron donor to produce the methanol. 65 2.Amethod assetforthinclaim1Whereintheadditional dehydrogenase enZymes are methanol dehydrogenase enzymes. 3. A method as set forth in claim 1 Wherein the alcohol dehydrogenase enZymes are other than methanol dehydro genase enzymes. and the like, cited in this speci?cation are hereby incorpo rated by reference. The discussion of the references herein is intendedmerelytosummariZetheassertionsmadebytheir to the method ofPDF Image | DEHYDROGENASE ENZYMATIC SYNTHESIS OF METHANOL

PDF Search Title:

DEHYDROGENASE ENZYMATIC SYNTHESIS OF METHANOLOriginal File Name Searched:

US6440711.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |