PDF Publication Title:

Text from PDF Page: 002

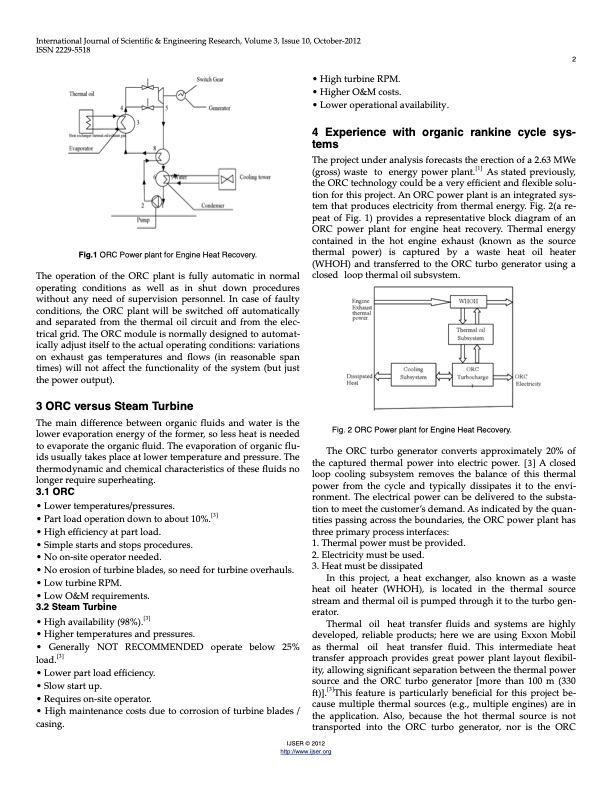

International Journal of Scientific & Engineering Research, Volume 3, Issue 10, October-2012 ISSN 2229-5518 2 Fig.1 ORC Power plant for Engine Heat Recovery. The operation of the ORC plant is fully automatic in normal operating conditions as well as in shut down procedures without any need of supervision personnel. In case of faulty conditions, the ORC plant will be switched off automatically and separated from the thermal oil circuit and from the elec- trical grid. The ORC module is normally designed to automat- ically adjust itself to the actual operating conditions: variations on exhaust gas temperatures and flows (in reasonable span times) will not affect the functionality of the system (but just the power output). 3 ORC versus Steam Turbine The main difference between organic fluids and water is the lower evaporation energy of the former, so less heat is needed to evaporate the organic fluid. The evaporation of organic flu- ids usually takes place at lower temperature and pressure. The thermodynamic and chemical characteristics of these fluids no longer require superheating. 3.1 ORC • Lower temperatures/pressures. • Part load operation down to about 10%.[3] • High efficiency at part load. • Simple starts and stops procedures. • No on-site operator needed. • No erosion of turbine blades, so need for turbine overhauls. • Low turbine RPM. • Low O&M requirements. 3.2 Steam Turbine • High availability (98%).[3] • Higher temperatures and pressures. • Generally NOT RECOMMENDED operate below 25% load.[3] • Lower part load efficiency. • Slow start up. • Requires on-site operator. • High maintenance costs due to corrosion of turbine blades / casing. • High turbine RPM. • Higher O&M costs. • Lower operational availability. 4 Experience with organic rankine cycle sys- tems The project under analysis forecasts the erection of a 2.63 MWe (gross) waste to energy power plant.[1] As stated previously, the ORC technology could be a very efficient and flexible solu- tion for this project. An ORC power plant is an integrated sys- tem that produces electricity from thermal energy. Fig. 2(a re- peat of Fig. 1) provides a representative block diagram of an ORC power plant for engine heat recovery. Thermal energy contained in the hot engine exhaust (known as the source thermal power) is captured by a waste heat oil heater (WHOH) and transferred to the ORC turbo generator using a closed loop thermal oil subsystem. IJSER © 2012 http://www.ijser.org Fig. 2 ORC Power plant for Engine Heat Recovery. The ORC turbo generator converts approximately 20% of the captured thermal power into electric power. [3] A closed loop cooling subsystem removes the balance of this thermal power from the cycle and typically dissipates it to the envi- ronment. The electrical power can be delivered to the substa- tion to meet the customer’s demand. As indicated by the quan- tities passing across the boundaries, the ORC power plant has three primary process interfaces: 1. Thermal power must be provided. 2. Electricity must be used. 3. Heat must be dissipated In this project, a heat exchanger, also known as a waste heat oil heater (WHOH), is located in the thermal source stream and thermal oil is pumped through it to the turbo gen- erator. Thermal oil heat transfer fluids and systems are highly developed, reliable products; here we are using Exxon Mobil as thermal oil heat transfer fluid. This intermediate heat transfer approach provides great power plant layout flexibil- ity, allowing significant separation between the thermal power source and the ORC turbo generator [more than 100 m (330 ft)].[3]This feature is particularly beneficial for this project be- cause multiple thermal sources (e.g., multiple engines) are in the application. Also, because the hot thermal source is not transported into the ORC turbo generator, nor is the ORCPDF Image | Waste Heat Recovery System by Using ORC

PDF Search Title:

Waste Heat Recovery System by Using ORCOriginal File Name Searched:

Waste_Heat_Recovery_System_by_Using_an_Organic_Rankine_Cycle_ORC.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |