PDF Publication Title:

Text from PDF Page: 002

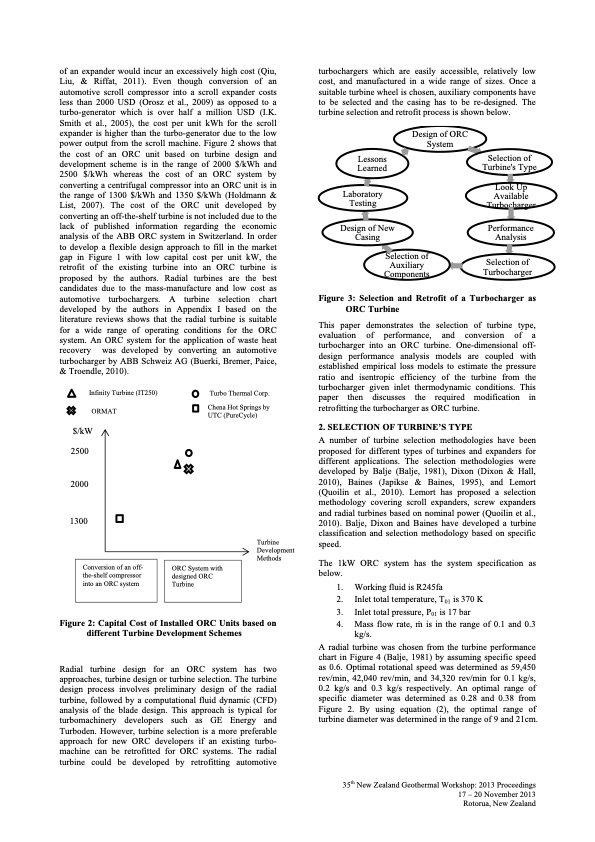

of an expander would incur an excessively high cost (Qiu, Liu, & Riffat, 2011). Even though conversion of an automotive scroll compressor into a scroll expander costs less than 2000 USD (Orosz et al., 2009) as opposed to a turbo-generator which is over half a million USD (I.K. Smith et al., 2005), the cost per unit kWh for the scroll expander is higher than the turbo-generator due to the low power output from the scroll machine. Figure 2 shows that the cost of an ORC unit based on turbine design and development scheme is in the range of 2000 $/kWh and 2500 $/kWh whereas the cost of an ORC system by converting a centrifugal compressor into an ORC unit is in the range of 1300 $/kWh and 1350 $/kWh (Holdmann & List, 2007). The cost of the ORC unit developed by converting an off-the-shelf turbine is not included due to the lack of published information regarding the economic analysis of the ABB ORC system in Switzerland. In order to develop a flexible design approach to fill in the market gap in Figure 1 with low capital cost per unit kW, the retrofit of the existing turbine into an ORC turbine is proposed by the authors. Radial turbines are the best candidates due to the mass-manufacture and low cost as automotive turbochargers. A turbine selection chart developed by the authors in Appendix I based on the literature reviews shows that the radial turbine is suitable for a wide range of operating conditions for the ORC system. An ORC system for the application of waste heat recovery was developed by converting an automotive turbocharger by ABB Schweiz AG (Buerki, Bremer, Paice, & Troendle, 2010). 2000 1300 Figure 2: Capital Cost of Installed ORC Units based on different Turbine Development Schemes Radial turbine design for an ORC system has two approaches, turbine design or turbine selection. The turbine design process involves preliminary design of the radial turbine, followed by a computational fluid dynamic (CFD) analysis of the blade design. This approach is typical for turbomachinery developers such as GE Energy and Turboden. However, turbine selection is a more preferable approach for new ORC developers if an existing turbo- machine can be retrofitted for ORC systems. The radial turbine could be developed by retrofitting automotive turbochargers which are easily accessible, relatively low cost, and manufactured in a wide range of sizes. Once a suitable turbine wheel is chosen, auxiliary components have to be selected and the casing has to be re-designed. The turbine selection and retrofit process is shown below. Design of ORC System Lessons Learned Laboratory Testing Design of New Casing Selection of Turbine's Type Look Up Available Turbocharger Performance Analysis Selection of Turbocharger Selection of Auxiliary Components Figure 3: Selection and Retrofit of a Turbocharger as ORC Turbine This paper demonstrates the selection of turbine type, evaluation of performance, and conversion of a turbocharger into an ORC turbine. One-dimensional off- design performance analysis models are coupled with established empirical loss models to estimate the pressure ratio and isentropic efficiency of the turbine from the turbocharger given inlet thermodynamic conditions. This paper then discusses the required modification in retrofitting the turbocharger as ORC turbine. 2. SELECTION OF TURBINE’S TYPE A number of turbine selection methodologies have been proposed for different types of turbines and expanders for different applications. The selection methodologies were developed by Balje (Balje, 1981), Dixon (Dixon & Hall, 2010), Baines (Japikse & Baines, 1995), and Lemort (Quoilin et al., 2010). Lemort has proposed a selection methodology covering scroll expanders, screw expanders and radial turbines based on nominal power (Quoilin et al., 2010). Balje, Dixon and Baines have developed a turbine classification and selection methodology based on specific speed. The 1kW ORC system has the system specification as below. 1. Working fluid is R245fa 2. Inlet total temperature, T01 is 370 K 3. Inlet total pressure, P01 is 17 bar 4. Mass flow rate, ṁ is in the range of 0.1 and 0.3 kg/s. A radial turbine was chosen from the turbine performance chart in Figure 4 (Balje, 1981) by assuming specific speed as 0.6. Optimal rotational speed was determined as 59,450 rev/min, 42,040 rev/min, and 34,320 rev/min for 0.1 kg/s, 0.2 kg/s and 0.3 kg/s respectively. An optimal range of specific diameter was determined as 0.28 and 0.38 from Figure 2. By using equation (2), the optimal range of turbine diameter was determined in the range of 9 and 21cm. 35th New Zealand Geothermal Workshop: 2013 Proceedings 17 – 20 November 2013 Rotorua, New Zealand $/kW Infinity Turbine (IT250) Turbo Thermal Corp. ORMA T Chena Hot Springs by UTC (PureCycle) 2500 Turbine Development Methods Conversion of an off- the-shelf compressor into an ORC system ORC System with designed ORC TurbinePDF Image | TURBOCHARGER AS TURBO-EXPANDER FOR ORGANIC RANKINE CYCLE

PDF Search Title:

TURBOCHARGER AS TURBO-EXPANDER FOR ORGANIC RANKINE CYCLEOriginal File Name Searched:

Wong_Final.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |