PDF Publication Title:

Text from PDF Page: 003

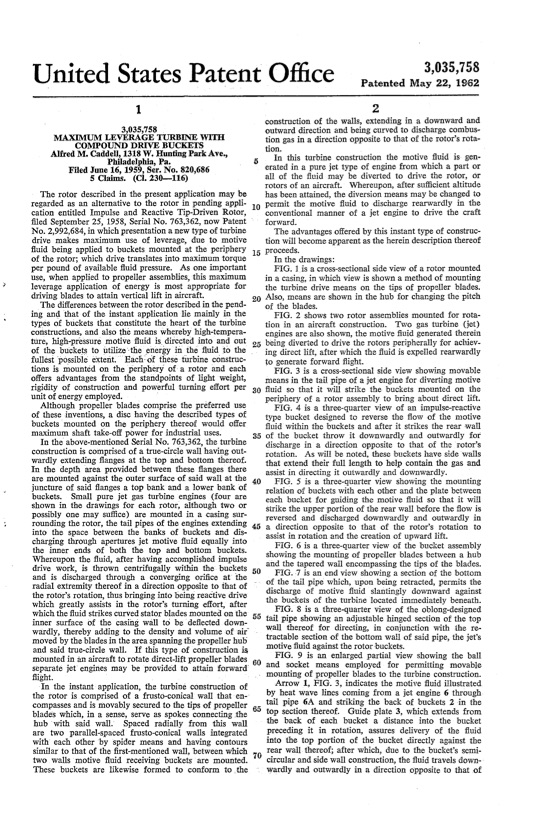

UnitedStatesPatent0 1 CC 3,035,758 Patented May 22, 1962 2 3,035,758 MAXIMUM LEVERAGE TURBINE WITH COMPOUND DRIVE BUCKETS AlfredM. Caddell,1318W. HuntingParkAve., Philadelphia,Pa. Filed June 16, 1959, Ser. No. 820,686 5Claims. (Cl.230—116) construction of the walls, extending in a downward and outward direction and being curved to discharge combus tion gas in a direction opposite to that of the rotor’s rota tion. In this turbine construction the motive ?uid isvgen erated in a pure jet type of engine from which a part or all of the ?uid may be diverted to drive the rotor, or rotorsofanaircraft. Whereupon,aftersu?icientaltitude has been attained, the diversion means may be changed to permit the motive ?uid to discharge rearwardly in the conventional manner of a jet engine to drive the craft The rotor described in the present application may be regarded as an alternative to the rotor in pending appli cation entitled Impulse and Reactive Tip-Driven Rotor, ?ledSeptember25,1958,SerialNo.763,362,nowPatent' forward. No. 2,992,684, in which presentation a new type of turbine The advantages offered by this instant type of construc drive makes maximum use of leverage, due to motive tionwillbecomeapparentasthehereindescriptionthereof ?uid being applied to buckets mounted at the periphery 15 proceeds. of the rotor; which drive translates into maximum torque perpoundofavailable?uidpressure. Asoneimportant use, when applied to propeller assemblies, this maximum leverage application of energy is most appropriate for drivingbladestoattainverticalliftinaircraft. Although propeller blades comprise the preferred use of these inventions, a disc having the described types of bucketsvmounted on the periphery thereof would offer maximum shaft take-01f power for industrial uses. In the drawings: FIG.lvisacross-sectionalsideviewofarotormounted in a casing, in which view is shown a method of mounting the turbine drive means on the tips of propeller blades. 20 Also,meansareshowninthehubforchangingthepitch of the blades. The di?erencesbetweentherotordescribedinthepend ing and that of the instant application lie mainly in the types of buckets that constitute the heart of the turbine constructions, and also the means whereby high-tempera ture,high-pressuremotive?uidis_directedintoandout 25 beingdivertedtodrivetherotorsperipherallyforachiev ofthebucketstoutilize-theenergyinthe?uidtothe , ingdirectlift,afterwhichthe?uidisexpelledrearwardly fullest possible extentf'Eachlof these turbine construc tions is mounted on the periphery of-a rotor and each offers advantages from the standpoints of light weight, rigidity of construction and powerful turning effort per 30 ?uid so that it will strike the buckets mounted on the unit of energy employed. ' FIG. 2 shows two rotor assemblies mounted for rota tion in an aircraft construction. Two gas turbine (jet) engines are also shown, the motive ?uid generated therein to generate forward ?ight. FIG. 3 is a cross-sectional side view showing movable means in the tail pipe of a jet engine for diverting motive periphery of a rotor assembly to bring about direct lift. FIG. 4 is a three-quarter View of an impulse-reactive type bucket designed to reverse the ?ow of the motive ?uid within the buckets and after it strikes the rear wall 35 of the bucket throw it downwardly and outwardly for discharge in a direction opposite to that of the rotor’s rotation. Aswillbenoted,thesebucketshavesidewalls that extend their full length to help contain the gas and In the‘above-mentioned Serial No. 763,362, the turbine construction is comprised of a true-circle wall having out wardly extending ?anges at the 'top and bottom thereof. In the depth ‘area provided between these ?anges there are mounted against the outer surface of said wall at the 40 juncture of said ?anges a top bank and a lower bank of buckets. Smallpurejetgasturbineengines(fourare shown in the drawings for each rotor, although two or possibly one may suffice) are mounted in a casing sur roundingtherotor,thetailpipesoftheenginesextending 45 a direction opposite to that of the rotor’s rotation to into the space between the banks of buckets and dis charging through apertures jet motive ?uid equally into the inner ends of both the top and bottom buckets. Whereupon the ?uid, after having accomplished impulse drive work, is thrown centrifugally within the buckets 50 and is discharged through a converging ori?ce at‘the radialextremitythereofinadirectionoppositetothatof aofthetailpipewhich,uponbeingretracted,permitsthe therotor’srotation,thusbringingintobeingreactivedrive which greatly assists in the rotor’s turning effort, after which the ?uid strikes curved stator blades mounted on the inner surface of the casing wall to be'de?ected down wardly, thereby adding to the density and volume of air" moved bythebladesintheareaspanningthepropellerhub andsaidtrue-circlewall. Ifthistypeofconstructionis mounted in an aircraft to rotate direct-lift propeller blades separate jet‘engines may be provided to attain forward‘ 60 and socket means employed for permitting movable ?ight. In the instant application, the turbine construction of . mounting of propeller blades to the turbine construction. Arrow 1, FIG. 3, indicates the motive ?uid illustrated by heat wave lines coming from a jet engine 6 through tailpipe6A andstrikingthebackofbuckets2inthe the rotor is comprised of a frusto-conical wall that en-' compassesandismovablysecuredtothetipsofpropeller blades which, in a sense, serve as spokes connecting .the 65 top section thereof. Guide plate 3, which extends from hub ‘with said wall; Spaced radially from this wall are two parallel-spaced frusto-conical walls integrated with‘ each other ‘by spider means and having contours similar to that of the ?rst-mentioned wall, between which two walls motive ?uid receiving buckets are mounted. 70 circularandsidewallconstruction,the?uidtravelsdown-i These buckets are likewise formed to conform to ,the wardly and outwardly in a direction opposite to that of assist in directing it outwardly and downwardly. FIG. 5 is a three-quarter View showing the mounting relation of buckets with each other and the plate between each bucket for guiding the motive ?uid so that it will strike the upper portion of the rear wall before the flow is reversed and discharged downwardly and outwardly in assist in rotation and the creation of upward lift. FIG. 6 is a three-quarter view of the bucket assembly showing the mounting of propeller blades between a hub and the tapered wail encompassing the tips of the blades. FIG. 7 is an end view showing a section of the bottom discharge of motive ?uid slantingly downward against the buckets of the turbine located immediately beneath. FIG. 8 is a three-quarter view of the oblong-designed tail pipe showing an adjustable hinged section of the top wall thereof for directing, in conjunction with the re tractable section of the bottom wall of said pipe, the jet’s motive ?uid against the rotor ‘buckets. FIG. 9 is an enlarged partial view showing the ball the back of each bucket a distance into the bucket preceding it in rotation, assures delivery of the ?uid into the top portion of the bucket directly against the rear wall thereof; after which, due to the bucket’s semiPDF Image | Leverage Turbine

PDF Search Title:

Leverage TurbineOriginal File Name Searched:

US3035758.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |