PDF Publication Title:

Text from PDF Page: 003

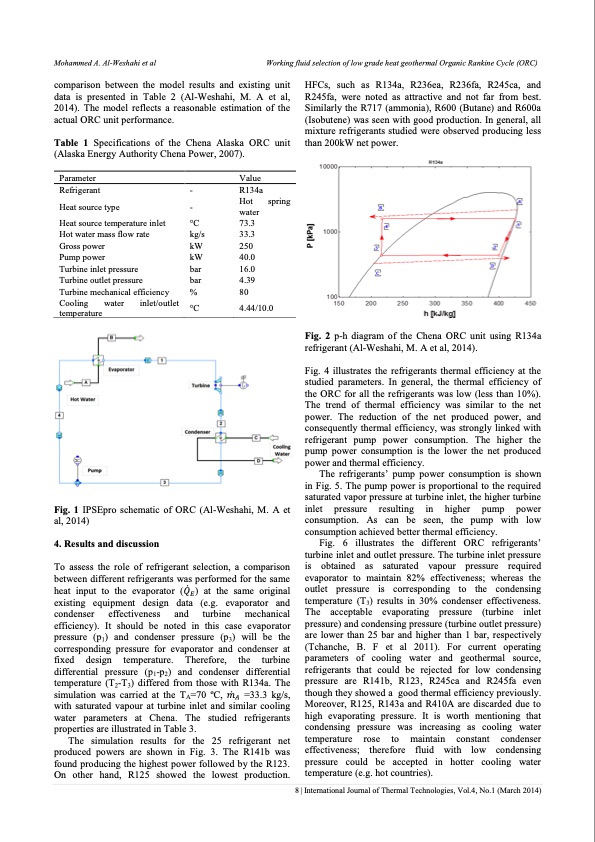

Mohammed A. Al-Weshahi et al Working fluid selection of low grade heat geothermal Organic Rankine Cycle (ORC) comparison between the model results and existing unit data is presented in Table 2 (Al-Weshahi, M. A et al, 2014). The model reflects a reasonable estimation of the actual ORC unit performance. Table 1 Specifications of the Chena Alaska ORC unit (Alaska Energy Authority Chena Power, 2007). Parameter Value Refrigerant - R134a Hot spring water Heat source temperature inlet °C 73.3 Hot water mass flow rate kg/s 33.3 Gross power kW 250 Pump power kW 40.0 Turbine inlet pressure bar 16.0 Turbine outlet pressure bar 4.39 Turbine mechanical efficiency % 80 HFCs, such as R134a, R236ea, R236fa, R245ca, and R245fa, were noted as attractive and not far from best. Similarly the R717 (ammonia), R600 (Butane) and R600a (Isobutene) was seen with good production. In general, all mixture refrigerants studied were observed producing less than 200kW net power. Fig. 2 p-h diagram of the Chena ORC unit using R134a refrigerant (Al-Weshahi, M. A et al, 2014). Fig. 4 illustrates the refrigerants thermal efficiency at the studied parameters. In general, the thermal efficiency of the ORC for all the refrigerants was low (less than 10%). The trend of thermal efficiency was similar to the net power. The reduction of the net produced power, and consequently thermal efficiency, was strongly linked with refrigerant pump power consumption. The higher the pump power consumption is the lower the net produced power and thermal efficiency. The refrigerants’ pump power consumption is shown in Fig. 5. The pump power is proportional to the required saturated vapor pressure at turbine inlet, the higher turbine inlet pressure resulting in higher pump power consumption. As can be seen, the pump with low consumption achieved better thermal efficiency. Fig. 6 illustrates the different ORC refrigerants’ turbine inlet and outlet pressure. The turbine inlet pressure is obtained as saturated vapour pressure required evaporator to maintain 82% effectiveness; whereas the outlet pressure is corresponding to the condensing temperature (T3) results in 30% condenser effectiveness. The acceptable evaporating pressure (turbine inlet pressure) and condensing pressure (turbine outlet pressure) are lower than 25 bar and higher than 1 bar, respectively (Tchanche, B. F et al 2011). For current operating parameters of cooling water and geothermal source, refrigerants that could be rejected for low condensing pressure are R141b, R123, R245ca and R245fa even though they showed a good thermal efficiency previously. Moreover, R125, R143a and R410A are discarded due to high evaporating pressure. It is worth mentioning that condensing pressure was increasing as cooling water temperature rose to maintain constant condenser effectiveness; therefore fluid with low condensing pressure could be accepted in hotter cooling water temperature (e.g. hot countries). Heat source type - Cooling temperature water inlet/outlet °C 4.44/10.0 Fig. 1 IPSEpro schematic of ORC (Al-Weshahi, M. A et al, 2014) 4. Results and discussion To assess the role of refrigerant selection, a comparison between different refrigerants was performed for the same heat input to the evaporator ( ̇ ) at the same original existing equipment design data (e.g. evaporator and condenser effectiveness and turbine mechanical efficiency). It should be noted in this case evaporator pressure (p1) and condenser pressure (p3) will be the corresponding pressure for evaporator and condenser at fixed design temperature. Therefore, the turbine differential pressure (p1-p2) and condenser differential temperature (T2-T3) differed from those with R134a. The simulation was carried at the TA=70 oC, ̇ =33.3 kg/s, with saturated vapour at turbine inlet and similar cooling water parameters at Chena. The studied refrigerants properties are illustrated in Table 3. The simulation results for the 25 refrigerant net produced powers are shown in Fig. 3. The R141b was found producing the highest power followed by the R123. On other hand, R125 showed the lowest production. 8 | International Journal of Thermal Technologies, Vol.4, No.1 (March 2014)PDF Image | Working fluid selection of low grade heat geothermal Organic Rankine Cycle

PDF Search Title:

Working fluid selection of low grade heat geothermal Organic Rankine CycleOriginal File Name Searched:

Paper26_121.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |