PDF Publication Title:

Text from PDF Page: 006

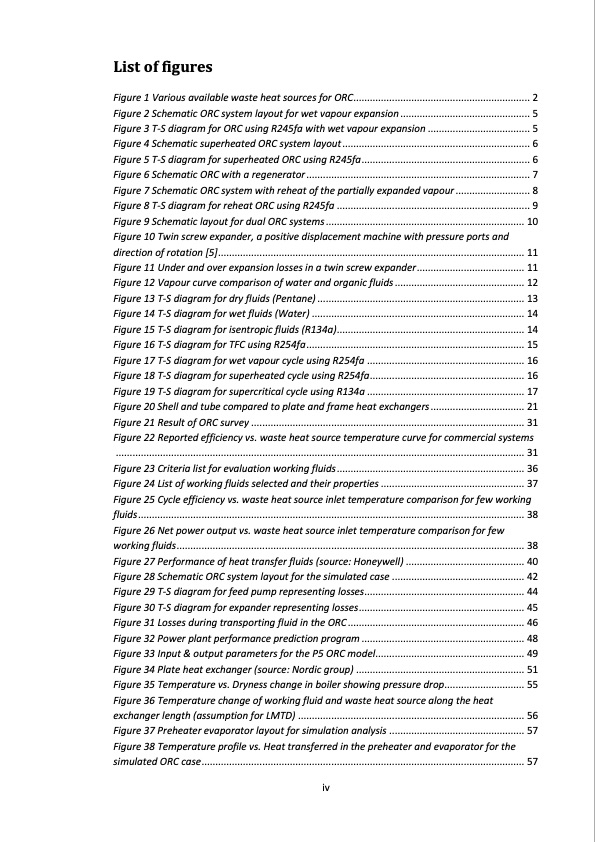

List of figures Figure 1 Various available waste heat sources for ORC................................................................ 2 Figure 2 Schematic ORC system layout for wet vapour expansion ............................................... 5 Figure 3 T-S diagram for ORC using R245fa with wet vapour expansion ..................................... 5 Figure 4 Schematic superheated ORC system layout .................................................................... 6 Figure 5 T-S diagram for superheated ORC using R245fa............................................................. 6 Figure 6 Schematic ORC with a regenerator ................................................................................. 7 Figure 7 Schematic ORC system with reheat of the partially expanded vapour ........................... 8 Figure 8 T-S diagram for reheat ORC using R245fa ...................................................................... 9 Figure 9 Schematic layout for dual ORC systems ........................................................................ 10 Figure 10 Twin screw expander, a positive displacement machine with pressure ports and direction of rotation [5]............................................................................................................... 11 Figure 11 Under and over expansion losses in a twin screw expander....................................... 11 Figure 12 Vapour curve comparison of water and organic fluids ............................................... 12 Figure 13 T-S diagram for dry fluids (Pentane) ........................................................................... 13 Figure 14 T-S diagram for wet fluids (Water) ............................................................................. 14 Figure 15 T-S diagram for isentropic fluids (R134a).................................................................... 14 Figure 16 T-S diagram for TFC using R254fa............................................................................... 15 Figure 17 T-S diagram for wet vapour cycle using R254fa ......................................................... 16 Figure 18 T-S diagram for superheated cycle using R254fa........................................................ 16 Figure 19 T-S diagram for supercritical cycle using R134a ......................................................... 17 Figure 20 Shell and tube compared to plate and frame heat exchangers .................................. 21 Figure 21 Result of ORC survey ................................................................................................... 31 Figure 22 Reported efficiency vs. waste heat source temperature curve for commercial systems .................................................................................................................................................... 31 Figure 23 Criteria list for evaluation working fluids.................................................................... 36 Figure 24 List of working fluids selected and their properties .................................................... 37 Figure 25 Cycle efficiency vs. waste heat source inlet temperature comparison for few working fluids............................................................................................................................................ 38 Figure 26 Net power output vs. waste heat source inlet temperature comparison for few working fluids.............................................................................................................................. 38 Figure 27 Performance of heat transfer fluids (source: Honeywell) ........................................... 40 Figure 28 Schematic ORC system layout for the simulated case ................................................ 42 Figure 29 T-S diagram for feed pump representing losses.......................................................... 44 Figure 30 T-S diagram for expander representing losses............................................................ 45 Figure 31 Losses during transporting fluid in the ORC ................................................................ 46 Figure 32 Power plant performance prediction program ........................................................... 48 Figure 33 Input & output parameters for the P5 ORC model...................................................... 49 Figure 34 Plate heat exchanger (source: Nordic group) ............................................................. 51 Figure 35 Temperature vs. Dryness change in boiler showing pressure drop............................. 55 Figure 36 Temperature change of working fluid and waste heat source along the heat exchanger length (assumption for LMTD) .................................................................................. 56 Figure 37 Preheater evaporator layout for simulation analysis ................................................. 57 Figure 38 Temperature profile vs. Heat transferred in the preheater and evaporator for the simulated ORC case..................................................................................................................... 57 ivPDF Image | study of ORC with the expansion process twin screw machines

PDF Search Title:

study of ORC with the expansion process twin screw machinesOriginal File Name Searched:

Panesar_MPhil.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |