PDF Publication Title:

Text from PDF Page: 041

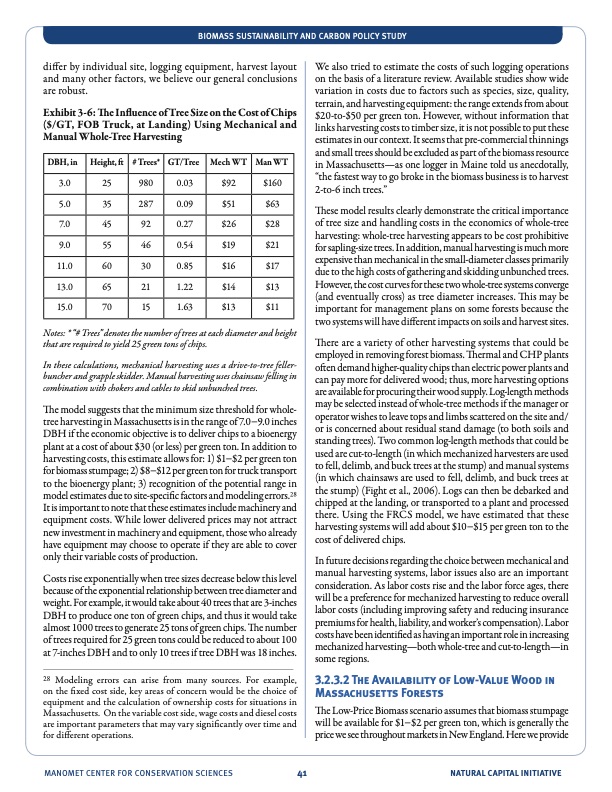

differ by individual site, logging equipment, harvest layout and many other factors, we believe our general conclusions are robust. Exhibit 3-6: The Influence of Tree Size on the Cost of Chips ($/GT, FOB Truck, at Landing) Using Mechanical and Manual Whole-Tree Harvesting We also tried to estimate the costs of such logging operations on the basis of a literature review. Available studies show wide variation in costs due to factors such as species, size, quality, terrain, and harvesting equipment: the range extends from about $20-to-$50 per green ton. However, without information that links harvesting costs to timber size, it is not possible to put these estimates in our context. It seems that pre-commercial thinnings and small trees should be excluded as part of the biomass resource in Massachusetts—as one logger in Maine told us anecdotally, “the fastest way to go broke in the biomass business is to harvest 2-to-6 inch trees.” These model results clearly demonstrate the critical importance of tree size and handling costs in the economics of whole-tree harvesting: whole-tree harvesting appears to be cost prohibitive for sapling-size trees. In addition, manual harvesting is much more expensive than mechanical in the small-diameter classes primarily due to the high costs of gathering and skidding unbunched trees. However, the cost curves for these two whole-tree systems converge (and eventually cross) as tree diameter increases. This may be important for management plans on some forests because the two systems will have different impacts on soils and harvest sites. There are a variety of other harvesting systems that could be employed in removing forest biomass. Thermal and CHP plants often demand higher-quality chips than electric power plants and can pay more for delivered wood; thus, more harvesting options are available for procuring their wood supply. Log-length methods may be selected instead of whole-tree methods if the manager or operator wishes to leave tops and limbs scattered on the site and/ or is concerned about residual stand damage (to both soils and standing trees). Two common log-length methods that could be used are cut-to-length (in which mechanized harvesters are used to fell, delimb, and buck trees at the stump) and manual systems (in which chainsaws are used to fell, delimb, and buck trees at the stump) (Fight et al., 2006). Logs can then be debarked and chipped at the landing, or transported to a plant and processed there. Using the FRCS model, we have estimated that these harvesting systems will add about $10−$15 per green ton to the cost of delivered chips. In future decisions regarding the choice between mechanical and manual harvesting systems, labor issues also are an important consideration. As labor costs rise and the labor force ages, there will be a preference for mechanized harvesting to reduce overall labor costs (including improving safety and reducing insurance premiums for health, liability, and worker’s compensation). Labor costs have been identified as having an important role in increasing mechanized harvesting—both whole-tree and cut-to-length—in some regions. 3.2.3.2 The Availability of Low-Value Wood in Massachusetts Forests The Low-Price Biomass scenario assumes that biomass stumpage will be available for $1−$2 per green ton, which is generally the price we see throughout markets in New England. Here we provide BIOMASS SUSTAINABILITY AND CARBON POLICY STUDY DBH, in 3.0 5.0 7.0 9.0 11.0 13.0 15.0 Height, ft 25 35 45 55 60 65 70 # Trees* GT/Tree 980 0.03 287 0.09 92 0.27 46 0.54 30 0.85 21 1.22 15 1.63 Mech WT Man WT $92 $160 $51 $63 $26 $28 $19 $21 $16 $17 $14 $13 $13 $11 Notes: * “# Trees” denotes the number of trees at each diameter and height that are required to yield 25 green tons of chips. In these calculations, mechanical harvesting uses a drive-to-tree feller- buncher and grapple skidder. Manual harvesting uses chainsaw felling in combination with chokers and cables to skid unbunched trees. The model suggests that the minimum size threshold for whole- tree harvesting in Massachusetts is in the range of 7.0−9.0 inches DBH if the economic objective is to deliver chips to a bioenergy plant at a cost of about $30 (or less) per green ton. In addition to harvesting costs, this estimate allows for: 1) $1−$2 per green ton for biomass stumpage; 2) $8−$12 per green ton for truck transport to the bioenergy plant; 3) recognition of the potential range in model estimates due to site-specific factors and modeling errors.28 It is important to note that these estimates include machinery and equipment costs. While lower delivered prices may not attract new investment in machinery and equipment, those who already have equipment may choose to operate if they are able to cover only their variable costs of production. Costs rise exponentially when tree sizes decrease below this level because of the exponential relationship between tree diameter and weight. For example, it would take about 40 trees that are 3-inches DBH to produce one ton of green chips, and thus it would take almost 1000 trees to generate 25 tons of green chips. The number of trees required for 25 green tons could be reduced to about 100 at 7-inches DBH and to only 10 trees if tree DBH was 18 inches. 28 Modeling errors can arise from many sources. For example, on the fixed cost side, key areas of concern would be the choice of equipment and the calculation of ownership costs for situations in Massachusetts. On the variable cost side, wage costs and diesel costs are important parameters that may vary significantly over time and for different operations. MANOMET CENTER FOR CONSERVATION SCIENCES 41 NATURAL CAPITAL INITIATIVEPDF Image | NATURAL CAPITAL INITIATIVE AT MANOMET

PDF Search Title:

NATURAL CAPITAL INITIATIVE AT MANOMETOriginal File Name Searched:

manomet_biomass_report_full_hirez.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |