PDF Publication Title:

Text from PDF Page: 022

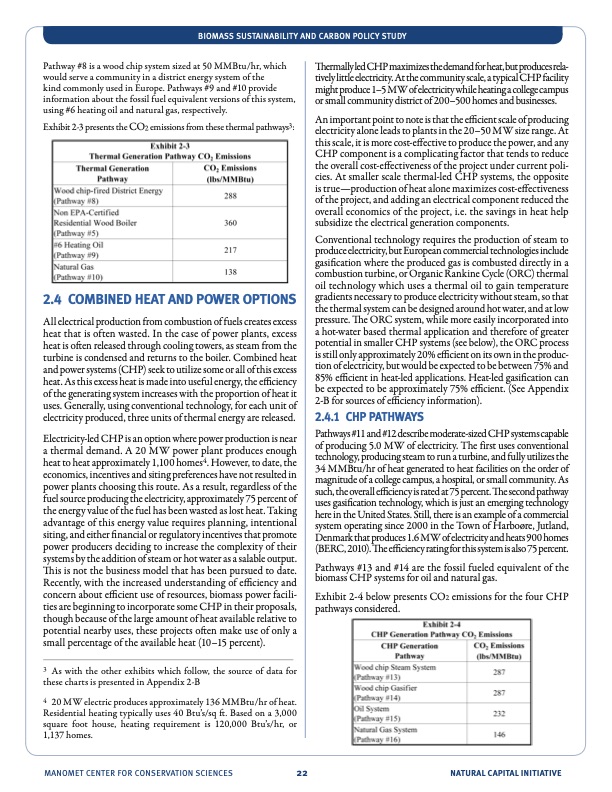

Pathway #8 is a wood chip system sized at 50 MMBtu/hr, which would serve a community in a district energy system of the kind commonly used in Europe. Pathways #9 and #10 provide information about the fossil fuel equivalent versions of this system, using #6 heating oil and natural gas, respectively. Exhibit 2-3 presents the CO2 emissions from these thermal pathways3: 2.4 COMBINEDHEATANDPOWEROPTIONS All electrical production from combustion of fuels creates excess heat that is often wasted. In the case of power plants, excess heat is often released through cooling towers, as steam from the turbine is condensed and returns to the boiler. Combined heat and power systems (CHP) seek to utilize some or all of this excess heat. As this excess heat is made into useful energy, the efficiency of the generating system increases with the proportion of heat it uses. Generally, using conventional technology, for each unit of electricity produced, three units of thermal energy are released. Electricity-led CHP is an option where power production is near a thermal demand. A 20 MW power plant produces enough heat to heat approximately 1,100 homes4. However, to date, the economics, incentives and siting preferences have not resulted in power plants choosing this route. As a result, regardless of the fuel source producing the electricity, approximately 75 percent of the energy value of the fuel has been wasted as lost heat. Taking advantage of this energy value requires planning, intentional siting, and either financial or regulatory incentives that promote power producers deciding to increase the complexity of their systems by the addition of steam or hot water as a salable output. This is not the business model that has been pursued to date. Recently, with the increased understanding of efficiency and concern about efficient use of resources, biomass power facili- ties are beginning to incorporate some CHP in their proposals, though because of the large amount of heat available relative to potential nearby uses, these projects often make use of only a small percentage of the available heat (10–15 percent). 3 As with the other exhibits which follow, the source of data for these charts is presented in Appendix 2-B 4 20 MW electric produces approximately 136 MMBtu/hr of heat. Residential heating typically uses 40 Btu’s/sq ft. Based on a 3,000 square foot house, heating requirement is 120,000 Btu’s/hr, or 1,137 homes. Thermally led CHP maximizes the demand for heat, but produces rela- tively little electricity. At the community scale, a typical CHP facility might produce 1–5 MW of electricity while heating a college campus or small community district of 200–500 homes and businesses. An important point to note is that the efficient scale of producing electricity alone leads to plants in the 20–50 MW size range. At this scale, it is more cost-effective to produce the power, and any CHP component is a complicating factor that tends to reduce the overall cost-effectiveness of the project under current poli- cies. At smaller scale thermal-led CHP systems, the opposite is true—production of heat alone maximizes cost-effectiveness of the project, and adding an electrical component reduced the overall economics of the project, i.e. the savings in heat help subsidize the electrical generation components. Conventional technology requires the production of steam to produce electricity, but European commercial technologies include gasification where the produced gas is combusted directly in a combustion turbine, or Organic Rankine Cycle (ORC) thermal oil technology which uses a thermal oil to gain temperature gradients necessary to produce electricity without steam, so that the thermal system can be designed around hot water, and at low pressure. The ORC system, while more easily incorporated into a hot-water based thermal application and therefore of greater potential in smaller CHP systems (see below), the ORC process is still only approximately 20% efficient on its own in the produc- tion of electricity, but would be expected to be between 75% and 85% efficient in heat-led applications. Heat-led gasification can be expected to be approximately 75% efficient. (See Appendix 2-B for sources of efficiency information). 2.4.1 CHP PATHWAYS Pathways #11 and #12 describe moderate-sized CHP systems capable of producing 5.0 MW of electricity. The first uses conventional technology, producing steam to run a turbine, and fully utilizes the 34 MMBtu/hr of heat generated to heat facilities on the order of magnitude of a college campus, a hospital, or small community. As such, the overall efficiency is rated at 75 percent. The second pathway uses gasification technology, which is just an emerging technology here in the United States. Still, there is an example of a commercial system operating since 2000 in the Town of Harboøre, Jutland, Denmark that produces 1.6 MW of electricity and heats 900 homes (BERC, 2010). The efficiency rating for this system is also 75 percent. Pathways #13 and #14 are the fossil fueled equivalent of the biomass CHP systems for oil and natural gas. Exhibit 2-4 below presents CO2 emissions for the four CHP pathways considered. BIOMASS SUSTAINABILITY AND CARBON POLICY STUDY MANOMET CENTER FOR CONSERVATION SCIENCES 22 NATURAL CAPITAL INITIATIVEPDF Image | NATURAL CAPITAL INITIATIVE AT MANOMET

PDF Search Title:

NATURAL CAPITAL INITIATIVE AT MANOMETOriginal File Name Searched:

manomet_biomass_report_full_hirez.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |