PDF Publication Title:

Text from PDF Page: 004

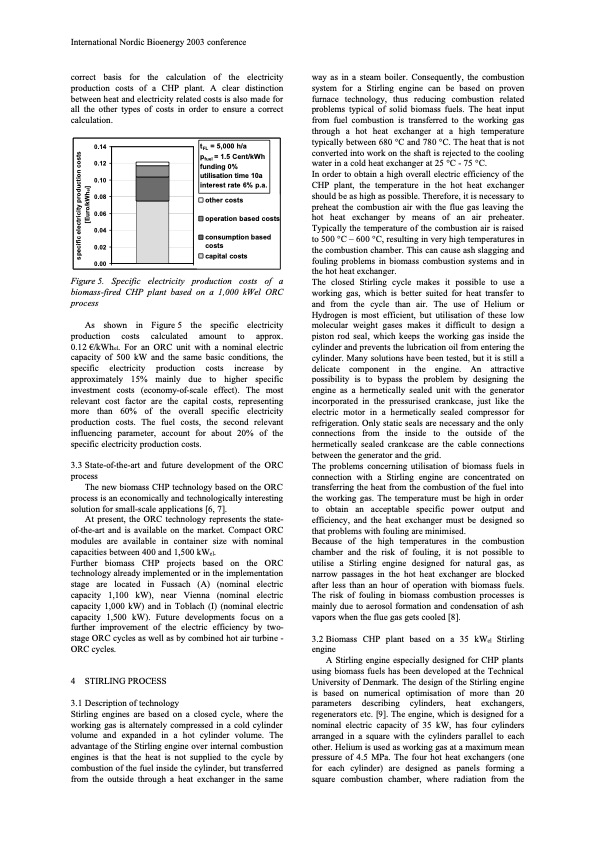

International Nordic Bioenergy 2003 conference correct basis for the calculation of the electricity production costs of a CHP plant. A clear distinction between heat and electricity related costs is also made for all the other types of costs in order to ensure a correct calculation. way as in a steam boiler. Consequently, the combustion system for a Stirling engine can be based on proven furnace technology, thus reducing combustion related problems typical of solid biomass fuels. The heat input from fuel combustion is transferred to the working gas through a hot heat exchanger at a high temperature typically between 680 °C and 780 °C. The heat that is not converted into work on the shaft is rejected to the cooling water in a cold heat exchanger at 25 °C - 75 °C. In order to obtain a high overall electric efficiency of the CHP plant, the temperature in the hot heat exchanger should be as high as possible. Therefore, it is necessary to preheat the combustion air with the flue gas leaving the hot heat exchanger by means of an air preheater. Typically the temperature of the combustion air is raised to 500 °C – 600 °C, resulting in very high temperatures in the combustion chamber. This can cause ash slagging and fouling problems in biomass combustion systems and in the hot heat exchanger. The closed Stirling cycle makes it possible to use a working gas, which is better suited for heat transfer to and from the cycle than air. The use of Helium or Hydrogen is most efficient, but utilisation of these low molecular weight gases makes it difficult to design a piston rod seal, which keeps the working gas inside the cylinder and prevents the lubrication oil from entering the cylinder. Many solutions have been tested, but it is still a delicate component in the engine. An attractive possibility is to bypass the problem by designing the engine as a hermetically sealed unit with the generator incorporated in the pressurised crankcase, just like the electric motor in a hermetically sealed compressor for refrigeration. Only static seals are necessary and the only connections from the inside to the outside of the hermetically sealed crankcase are the cable connections between the generator and the grid. The problems concerning utilisation of biomass fuels in connection with a Stirling engine are concentrated on transferring the heat from the combustion of the fuel into the working gas. The temperature must be high in order to obtain an acceptable specific power output and efficiency, and the heat exchanger must be designed so that problems with fouling are minimised. Because of the high temperatures in the combustion chamber and the risk of fouling, it is not possible to utilise a Stirling engine designed for natural gas, as narrow passages in the hot heat exchanger are blocked after less than an hour of operation with biomass fuels. The risk of fouling in biomass combustion processes is mainly due to aerosol formation and condensation of ash vapors when the flue gas gets cooled [8]. 3.2 Biomass CHP plant based on a 35 kWel Stirling engine A Stirling engine especially designed for CHP plants using biomass fuels has been developed at the Technical University of Denmark. The design of the Stirling engine is based on numerical optimisation of more than 20 parameters describing cylinders, heat exchangers, regenerators etc. [9]. The engine, which is designed for a nominal electric capacity of 35 kW, has four cylinders arranged in a square with the cylinders parallel to each other. Helium is used as working gas at a maximum mean pressure of 4.5 MPa. The four hot heat exchangers (one for each cylinder) are designed as panels forming a square combustion chamber, where radiation from the 0.14 0.12 0.10 0.08 0.06 0.04 0.02 0.00 tFL = 5,000 h/a pfuel = 1.5 Cent/kWh funding 0% utilisation time 10a interest rate 6% p.a. other costs operation based costs consumption based costs capital costs Figure5. Specific electricity production costs of a biomass-fired CHP plant based on a 1,000 kWel ORC process As shown in Figure5 the specific electricity production costs calculated amount to approx. 0.12 €/kWhel. For an ORC unit with a nominal electric capacity of 500 kW and the same basic conditions, the specific electricity production costs increase by approximately 15% mainly due to higher specific investment costs (economy-of-scale effect). The most relevant cost factor are the capital costs, representing more than 60% of the overall specific electricity production costs. The fuel costs, the second relevant influencing parameter, account for about 20% of the specific electricity production costs. 3.3 State-of-the-art and future development of the ORC process The new biomass CHP technology based on the ORC process is an economically and technologically interesting solution for small-scale applications [6, 7]. At present, the ORC technology represents the state- of-the-art and is available on the market. Compact ORC modules are available in container size with nominal capacities between 400 and 1,500 kWel. Further biomass CHP projects based on the ORC technology already implemented or in the implementation stage are located in Fussach (A) (nominal electric capacity 1,100 kW), near Vienna (nominal electric capacity 1,000 kW) and in Toblach (I) (nominal electric capacity 1,500 kW). Future developments focus on a further improvement of the electric efficiency by two- stage ORC cycles as well as by combined hot air turbine - ORC cycles. 4 STIRLING PROCESS 3.1 Description of technology Stirling engines are based on a closed cycle, where the working gas is alternately compressed in a cold cylinder volume and expanded in a hot cylinder volume. The advantage of the Stirling engine over internal combustion engines is that the heat is not supplied to the cycle by combustion of the fuel inside the cylinder, but transferred from the outside through a heat exchanger in the same specific electricity production costs [Euro/kWhel]PDF Image | FUTURE DEVELOPMENTS REGARDING SMALL-SCALE BIOMASS CHP

PDF Search Title:

FUTURE DEVELOPMENTS REGARDING SMALL-SCALE BIOMASS CHPOriginal File Name Searched:

Paper_Obernberger_SmallScaleCHP_NordicConference_2003_10_27.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |