PDF Publication Title:

Text from PDF Page: 002

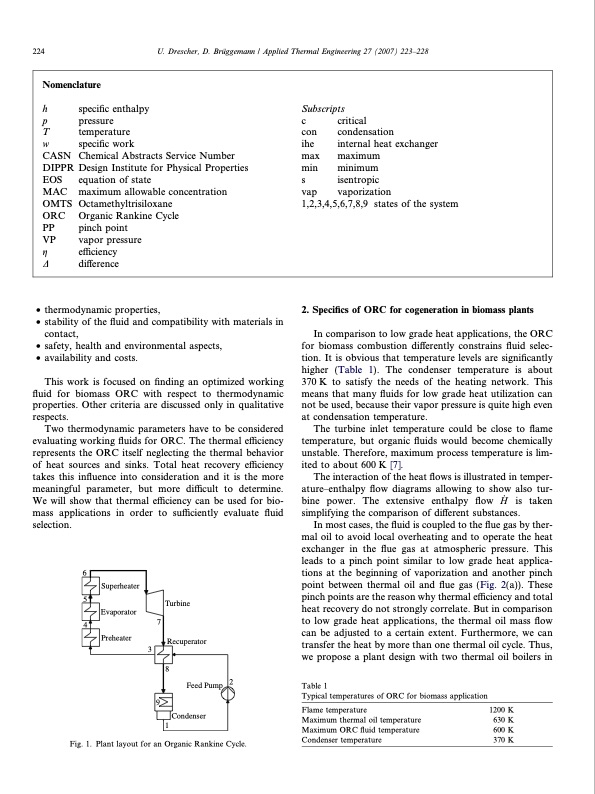

224 U. Drescher, D. Bru ̈ggemann / Applied Thermal Engineering 27 (2007) 223–228 Nomenclature h specific enthalpy p pressure T temperature w specific work CASN Chemical Abstracts Service Number DIPPR Design Institute for Physical Properties EOS equation of state MAC maximum allowable concentration OMTS Octamethyltrisiloxane ORC Organic Rankine Cycle PP pinch point VP vapor pressure g efficiency D difference Subscripts c critical con condensation ihe internal heat exchanger max maximum min minimum s isentropic vap vaporization 1,2,3,4,5,6,7,8,9 states of the system • thermodynamic properties, • stability of the fluid and compatibility with materials in contact, • safety, health and environmental aspects, • availability and costs. This work is focused on finding an optimized working fluid for biomass ORC with respect to thermodynamic properties. Other criteria are discussed only in qualitative respects. Two thermodynamic parameters have to be considered evaluating working fluids for ORC. The thermal efficiency represents the ORC itself neglecting the thermal behavior of heat sources and sinks. Total heat recovery efficiency takes this influence into consideration and it is the more meaningful parameter, but more difficult to determine. We will show that thermal efficiency can be used for bio- mass applications in order to sufficiently evaluate fluid selection. 2. Specifics of ORC for cogeneration in biomass plants In comparison to low grade heat applications, the ORC for biomass combustion differently constrains fluid selec- tion. It is obvious that temperature levels are significantly higher (Table 1). The condenser temperature is about 370 K to satisfy the needs of the heating network. This means that many fluids for low grade heat utilization can not be used, because their vapor pressure is quite high even at condensation temperature. The turbine inlet temperature could be close to flame temperature, but organic fluids would become chemically unstable. Therefore, maximum process temperature is lim- ited to about 600 K [7]. The interaction of the heat flows is illustrated in temper- ature–enthalpy flow diagrams allowing to show also tur- bine power. The extensive enthalpy flow H_ is taken simplifying the comparison of different substances. In most cases, the fluid is coupled to the flue gas by ther- mal oil to avoid local overheating and to operate the heat exchanger in the flue gas at atmospheric pressure. This leads to a pinch point similar to low grade heat applica- tions at the beginning of vaporization and another pinch point between thermal oil and flue gas (Fig. 2(a)). These pinch points are the reason why thermal efficiency and total heat recovery do not strongly correlate. But in comparison to low grade heat applications, the thermal oil mass flow can be adjusted to a certain extent. Furthermore, we can transfer the heat by more than one thermal oil cycle. Thus, we propose a plant design with two thermal oil boilers in 6 Superheater 5 Evaporator 4 Preheater 9 Turbine 7 Recuperator 3 8 Feed Pump 2 Condenser 1 Fig. 1. Plant layout for an Organic Rankine Cycle. Table 1 Typical temperatures of ORC for biomass application Flame temperature Maximum thermal oil temperature Maximum ORC fluid temperature Condenser temperature 1200 K 630 K 600 K 370 KPDF Image | Fluid selection for the Organic Rankine Cycle (ORC) in biomass

PDF Search Title:

Fluid selection for the Organic Rankine Cycle (ORC) in biomassOriginal File Name Searched:

ORC_Fluid_selection.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |