PDF Publication Title:

Text from PDF Page: 002

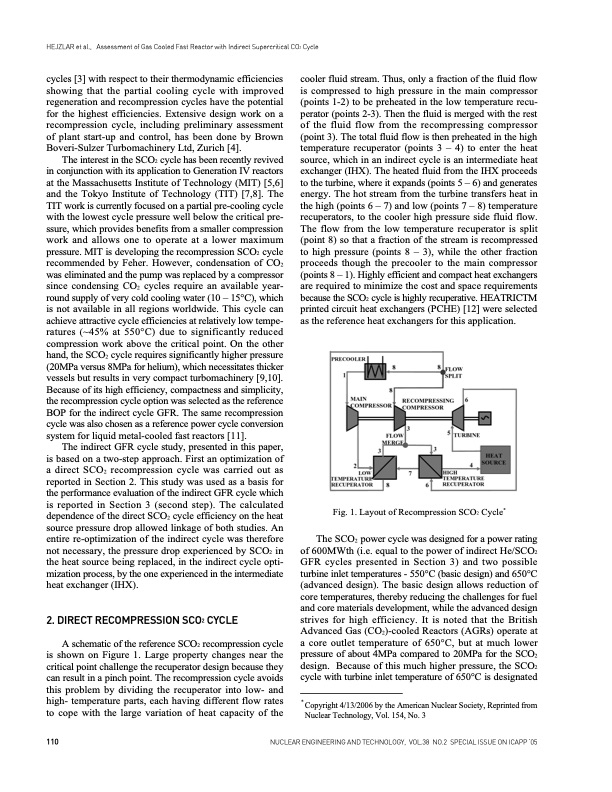

HEJZLARetal., AssessmentofGasCooledFastReactorwithIndirectSupercriticalCO2Cycle cycles [3] with respect to their thermodynamic efficiencies showing that the partial cooling cycle with improved regeneration and recompression cycles have the potential for the highest efficiencies. Extensive design work on a recompression cycle, including preliminary assessment of plant start-up and control, has been done by Brown Boveri-Sulzer Turbomachinery Ltd, Zurich [4]. The interest in the SCO2 cycle has been recently revived in conjunction with its application to Generation IV reactors at the Massachusetts Institute of Technology (MIT) [5,6] and the Tokyo Institute of Technology (TIT) [7,8]. The TIT work is currently focused on a partial pre-cooling cycle with the lowest cycle pressure well below the critical pre- ssure, which provides benefits from a smaller compression work and allows one to operate at a lower maximum pressure. MIT is developing the recompression SCO2 cycle recommended by Feher. However, condensation of CO2 was eliminated and the pump was replaced by a compressor since condensing CO2 cycles require an available year- round supply of very cold cooling water (10 – 15°C), which is not available in all regions worldwide. This cycle can achieve attractive cycle efficiencies at relatively low tempe- ratures (~45% at 550°C) due to significantly reduced compression work above the critical point. On the other hand, the SCO2 cycle requires significantly higher pressure (20MPa versus 8MPa for helium), which necessitates thicker vessels but results in very compact turbomachinery [9,10]. Because of its high efficiency, compactness and simplicity, the recompression cycle option was selected as the reference BOP for the indirect cycle GFR. The same recompression cycle was also chosen as a reference power cycle conversion system for liquid metal-cooled fast reactors [11]. The indirect GFR cycle study, presented in this paper, is based on a two-step approach. First an optimization of a direct SCO2 recompression cycle was carried out as reported in Section 2. This study was used as a basis for the performance evaluation of the indirect GFR cycle which is reported in Section 3 (second step). The calculated dependence of the direct SCO2 cycle efficiency on the heat source pressure drop allowed linkage of both studies. An entire re-optimization of the indirect cycle was therefore not necessary, the pressure drop experienced by SCO2 in the heat source being replaced, in the indirect cycle opti- mization process, by the one experienced in the intermediate heat exchanger (IHX). 2. DIRECT RECOMPRESSION SCO2 CYCLE A schematic of the reference SCO2 recompression cycle is shown on Figure 1. Large property changes near the critical point challenge the recuperator design because they can result in a pinch point. The recompression cycle avoids this problem by dividing the recuperator into low- and high- temperature parts, each having different flow rates to cope with the large variation of heat capacity of the cooler fluid stream. Thus, only a fraction of the fluid flow is compressed to high pressure in the main compressor (points 1-2) to be preheated in the low temperature recu- perator (points 2-3). Then the fluid is merged with the rest of the fluid flow from the recompressing compressor (point 3). The total fluid flow is then preheated in the high temperature recuperator (points 3 – 4) to enter the heat source, which in an indirect cycle is an intermediate heat exchanger (IHX). The heated fluid from the IHX proceeds to the turbine, where it expands (points 5 – 6) and generates energy. The hot stream from the turbine transfers heat in the high (points 6 – 7) and low (points 7 – 8) temperature recuperators, to the cooler high pressure side fluid flow. The flow from the low temperature recuperator is split (point 8) so that a fraction of the stream is recompressed to high pressure (points 8 – 3), while the other fraction proceeds though the precooler to the main compressor (points 8 – 1). Highly efficient and compact heat exchangers are required to minimize the cost and space requirements because the SCO2 cycle is highly recuperative. HEATRICTM printed circuit heat exchangers (PCHE) [12] were selected as the reference heat exchangers for this application. The SCO2 power cycle was designed for a power rating of 600MWth (i.e. equal to the power of indirect He/SCO2 GFR cycles presented in Section 3) and two possible turbine inlet temperatures - 550°C (basic design) and 650°C (advanced design). The basic design allows reduction of core temperatures, thereby reducing the challenges for fuel and core materials development, while the advanced design strives for high efficiency. It is noted that the British Advanced Gas (CO2)-cooled Reactors (AGRs) operate at a core outlet temperature of 650°C, but at much lower pressure of about 4MPa compared to 20MPa for the SCO2 design. Because of this much higher pressure, the SCO2 cycle with turbine inlet temperature of 650°C is designated Fig. 1. Layout of Recompression SCO2 Cycle* * Copyright 4/13/2006 by the American Nuclear Society, Reprinted from Nuclear Technology, Vol. 154, No. 3 110 NUCLEAR ENGINEERING AND TECHNOLOGY, VOL.38 NO.2 SPECIAL ISSUE ON ICAPP ‘05PDF Image | GAS COOLED FAST REACTOR WITH INDIRECT SUPERCRITICAL CO2

PDF Search Title:

GAS COOLED FAST REACTOR WITH INDIRECT SUPERCRITICAL CO2Original File Name Searched:

Infinity_JK0380109.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |