PDF Publication Title:

Text from PDF Page: 044

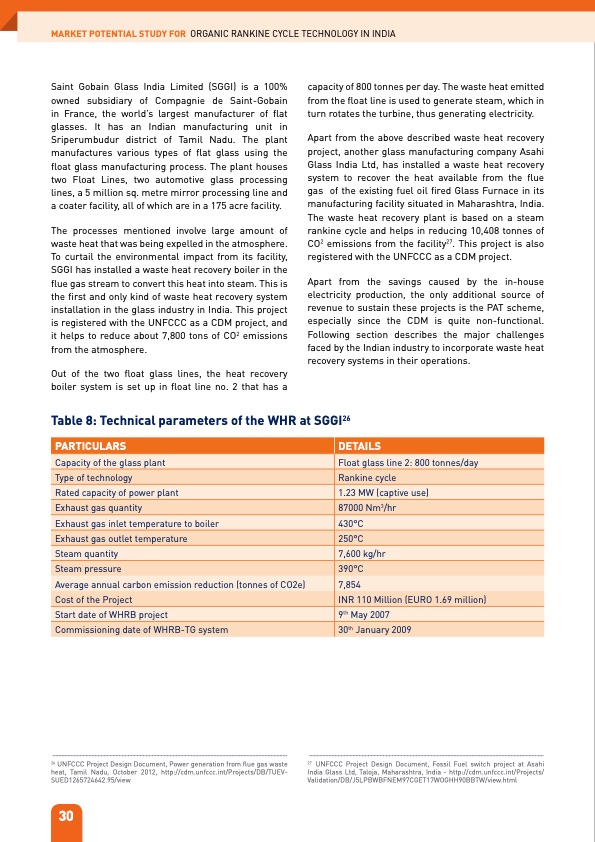

MARKET POTENTIAL STUDY FOR ORGANIC RANKINE CYCLE TECHNOLOGY IN INDIA Saint Gobain Glass India Limited (SGGI) is a 100% owned subsidiary of Compagnie de Saint-Gobain in France, the world’s largest manufacturer of flat glasses. It has an Indian manufacturing unit in Sriperumbudur district of Tamil Nadu. The plant manufactures various types of flat glass using the float glass manufacturing process. The plant houses two Float Lines, two automotive glass processing lines, a 5 million sq. metre mirror processing line and a coater facility, all of which are in a 175 acre facility. The processes mentioned involve large amount of waste heat that was being expelled in the atmosphere. To curtail the environmental impact from its facility, SGGI has installed a waste heat recovery boiler in the flue gas stream to convert this heat into steam. This is the first and only kind of waste heat recovery system installation in the glass industry in India. This project is registered with the UNFCCC as a CDM project, and it helps to reduce about 7,800 tons of CO2 emissions from the atmosphere. Out of the two float glass lines, the heat recovery boiler system is set up in float line no. 2 that has a capacity of 800 tonnes per day. The waste heat emitted from the float line is used to generate steam, which in turn rotates the turbine, thus generating electricity. Apart from the above described waste heat recovery project, another glass manufacturing company Asahi Glass India Ltd, has installed a waste heat recovery system to recover the heat available from the flue gas of the existing fuel oil fired Glass Furnace in its manufacturing facility situated in Maharashtra, India. The waste heat recovery plant is based on a steam rankine cycle and helps in reducing 10,408 tonnes of CO2 emissions from the facility27. This project is also registered with the UNFCCC as a CDM project. Apart from the savings caused by the in-house electricity production, the only additional source of revenue to sustain these projects is the PAT scheme, especially since the CDM is quite non-functional. Following section describes the major challenges faced by the Indian industry to incorporate waste heat recovery systems in their operations. table 8: technical parameters of the whr at sggi26 Particulars DEtails Capacity of the glass plant Float glass line 2: 800 tonnes/day Type of technology Rankine cycle Rated capacity of power plant 1.23 MW (captive use) Exhaust gas quantity 87000 Nm3/hr Exhaust gas inlet temperature to boiler 430°C Exhaust gas outlet temperature 250°C Steam quantity 7,600 kg/hr Steam pressure 390°C Average annual carbon emission reduction (tonnes of CO2e) 7,854 Cost of the Project INR 110 Million (EURO 1.69 million) Start date of WHRB project 9th May 2007 Commissioning date of WHRB-TG system 30th January 2009 26 UNFCCC Project Design Document, Power generation from flue gas waste heat, Tamil Nadu, October 2012, http://cdm.unfccc.int/Projects/DB/TUEV- SUED1265724642.95/view 27 UNFCCC Project Design Document, Fossil Fuel switch project at Asahi India Glass Ltd, Taloja, Maharashtra, India - http://cdm.unfccc.int/Projects/ Validation/DB/J5LPBWBFNEM97CGET17WOGHH90BBTW/view.html 30PDF Image | ORGANIC RANKINE CYCLE TECHNOLOGY IN INDIA

PDF Search Title:

ORGANIC RANKINE CYCLE TECHNOLOGY IN INDIAOriginal File Name Searched:

giz2014_en_market_potential_study_organic_rankine_cycle_technology_india.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |