PDF Publication Title:

Text from PDF Page: 003

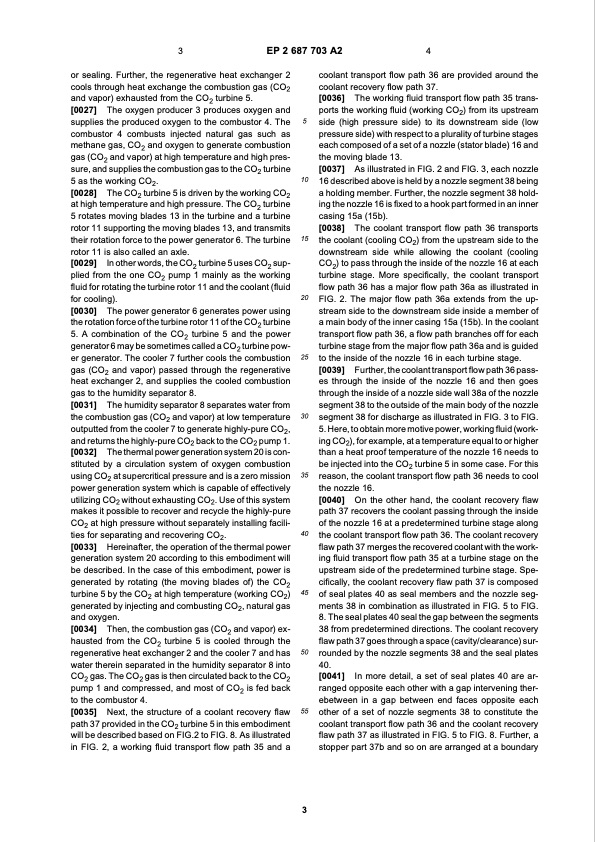

3 EP 2 687 703 A2 4 or sealing. Further, the regenerative heat exchanger 2 cools through heat exchange the combustion gas (CO2 and vapor) exhausted from the CO2 turbine 5. [0027] The oxygen producer 3 produces oxygen and supplies the produced oxygen to the combustor 4. The combustor 4 combusts injected natural gas such as methane gas, CO2 and oxygen to generate combustion gas (CO2 and vapor) at high temperature and high pres- sure, and supplies the combustion gas to the CO2 turbine 5 as the working CO2. [0028] The CO2 turbine 5 is driven by the working CO2 at high temperature and high pressure. The CO2 turbine 5 rotates moving blades 13 in the turbine and a turbine rotor 11 supporting the moving blades 13, and transmits their rotation force to the power generator 6. The turbine rotor 11 is also called an axle. [0029] In other words, the CO2 turbine 5 uses CO2 sup- plied from the one CO2 pump 1 mainly as the working fluid for rotating the turbine rotor 11 and the coolant (fluid for cooling). [0030] The power generator 6 generates power using the rotation force of the turbine rotor 11 of the CO2 turbine 5. A combination of the CO2 turbine 5 and the power generator 6 may be sometimes called a CO2 turbine pow- er generator. The cooler 7 further cools the combustion gas (CO2 and vapor) passed through the regenerative heat exchanger 2, and supplies the cooled combustion gas to the humidity separator 8. [0031] The humidity separator 8 separates water from the combustion gas (CO2 and vapor) at low temperature outputted from the cooler 7 to generate highly-pure CO2, and returns the highly-pure CO2 back to the CO2 pump 1. [0032] The thermal power generation system 20 is con- stituted by a circulation system of oxygen combustion using CO2 at supercritical pressure and is a zero mission power generation system which is capable of effectively utilizing CO2 without exhausting CO2. Use of this system makes it possible to recover and recycle the highly-pure CO2 at high pressure without separately installing facili- ties for separating and recovering CO2. [0033] Hereinafter, the operation of the thermal power generation system 20 according to this embodiment will be described. In the case of this embodiment, power is generated by rotating (the moving blades of) the CO2 turbine 5 by the CO2 at high temperature (working CO2) generated by injecting and combusting CO2, natural gas and oxygen. [0034] Then, the combustion gas (CO2 and vapor) ex- hausted from the CO2 turbine 5 is cooled through the regenerative heat exchanger 2 and the cooler 7 and has water therein separated in the humidity separator 8 into CO2 gas. The CO2 gas is then circulated back to the CO2 pump 1 and compressed, and most of CO2 is fed back to the combustor 4. [0035] Next, the structure of a coolant recovery flaw path 37 provided in the CO2 turbine 5 in this embodiment will be described based on FIG.2 to FIG. 8. As illustrated in FIG. 2, a working fluid transport flow path 35 and a coolant transport flow path 36 are provided around the coolant recovery flow path 37. [0036] The working fluid transport flow path 35 trans- ports the working fluid (working CO2) from its upstream side (high pressure side) to its downstream side (low pressure side) with respect to a plurality of turbine stages each composed of a set of a nozzle (stator blade) 16 and the moving blade 13. [0037] As illustrated in FIG. 2 and FIG. 3, each nozzle 16 described above is held by a nozzle segment 38 being a holding member. Further, the nozzle segment 38 hold- ing the nozzle 16 is fixed to a hook part formed in an inner casing 15a (15b). [0038] The coolant transport flow path 36 transports the coolant (cooling CO2) from the upstream side to the downstream side while allowing the coolant (cooling CO2) to pass through the inside of the nozzle 16 at each turbine stage. More specifically, the coolant transport flow path 36 has a major flow path 36a as illustrated in FIG. 2. The major flow path 36a extends from the up- stream side to the downstream side inside a member of a main body of the inner casing 15a (15b). In the coolant transport flow path 36, a flow path branches off for each turbine stage from the major flow path 36a and is guided to the inside of the nozzle 16 in each turbine stage. [0039] Further, the coolant transport flow path 36 pass- es through the inside of the nozzle 16 and then goes through the inside of a nozzle side wall 38a of the nozzle segment 38 to the outside of the main body of the nozzle segment 38 for discharge as illustrated in FIG. 3 to FIG. 5. Here, to obtain more motive power, working fluid (work- ing CO2), for example, at a temperature equal to or higher than a heat proof temperature of the nozzle 16 needs to be injected into the CO2 turbine 5 in some case. For this reason, the coolant transport flow path 36 needs to cool the nozzle 16. [0040] On the other hand, the coolant recovery flaw path 37 recovers the coolant passing through the inside of the nozzle 16 at a predetermined turbine stage along the coolant transport flow path 36. The coolant recovery flaw path 37 merges the recovered coolant with the work- ing fluid transport flow path 35 at a turbine stage on the upstream side of the predetermined turbine stage. Spe- cifically, the coolant recovery flaw path 37 is composed of seal plates 40 as seal members and the nozzle seg- ments 38 in combination as illustrated in FIG. 5 to FIG. 8. The seal plates 40 seal the gap between the segments 38 from predetermined directions. The coolant recovery flaw path 37 goes through a space (cavity/clearance) sur- rounded by the nozzle segments 38 and the seal plates 40. [0041] In more detail, a set of seal plates 40 are ar- ranged opposite each other with a gap intervening ther- ebetween in a gap between end faces opposite each other of a set of nozzle segments 38 to constitute the coolant transport flow path 36 and the coolant recovery flaw path 37 as illustrated in FIG. 5 to FIG. 8. Further, a stopper part 37b and so on are arranged at a boundary 5 10 15 20 25 30 35 40 45 50 55 3PDF Image | EP 2 687 703 A2

PDF Search Title:

EP 2 687 703 A2Original File Name Searched:

EP2687703A2.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |