PDF Publication Title:

Text from PDF Page: 002

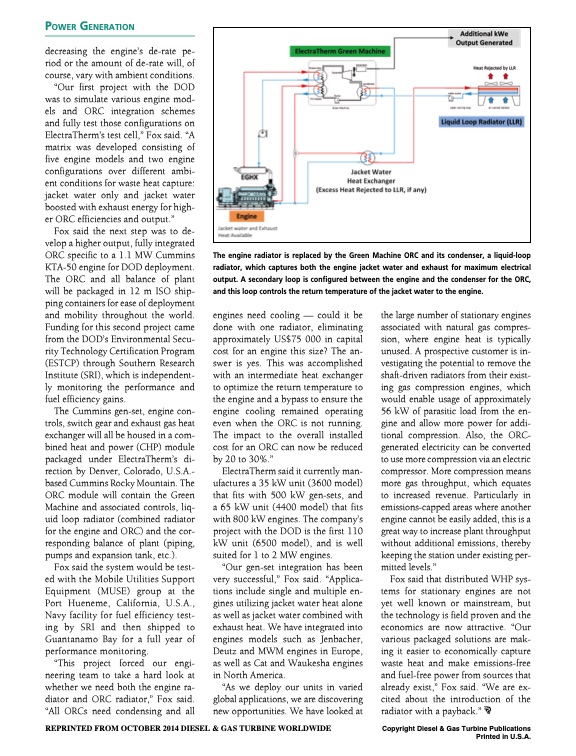

Power Generation decreasing the engine’s de-rate pe- riod or the amount of de-rate will, of course, vary with ambient conditions. “Our first project with the DOD was to simulate various engine mod- els and ORC integration schemes and fully test those configurations on ElectraTherm’s test cell,” Fox said. “A matrix was developed consisting of five engine models and two engine configurations over different ambi- ent conditions for waste heat capture: jacket water only and jacket water boosted with exhaust energy for high- er ORC efficiencies and output.” Fox said the next step was to de- velop a higher output, fully integrated ORC specific to a 1.1 MW Cummins KTA-50 engine for DOD deployment. The ORC and all balance of plant will be packaged in 12 m ISO ship- ping containers for ease of deployment and mobility throughout the world. Funding for this second project came from the DOD’s Environmental Secu- rity Technology Certification Program (ESTCP) through Southern Research Institute (SRI), which is independent- ly monitoring the performance and fuel efficiency gains. The Cummins gen-set, engine con- trols, switch gear and exhaust gas heat exchanger will all be housed in a com- bined heat and power (CHP) module packaged under ElectraTherm’s di- rection by Denver, Colorado, U.S.A.- based Cummins Rocky Mountain. The ORC module will contain the Green Machine and associated controls, liq- uid loop radiator (combined radiator for the engine and ORC) and the cor- responding balance of plant (piping, pumps and expansion tank, etc.). Fox said the system would be test- ed with the Mobile Utilities Support Equipment (MUSE) group at the Port Hueneme, California, U.S.A., Navy facility for fuel efficiency test- ing by SRI and then shipped to Guantanamo Bay for a full year of performance monitoring. “This project forced our engi- neering team to take a hard look at whether we need both the engine ra- diator and ORC radiator,” Fox said. “All ORCs need condensing and all The engine radiator is replaced by the Green Machine ORC and its condenser, a liquid-loop radiator, which captures both the engine jacket water and exhaust for maximum electrical output. A secondary loop is configured between the engine and the condenser for the ORC, and this loop controls the return temperature of the jacket water to the engine. REPRINTED FROM OCTOBER 2014 DIESEL & GAS TURBINE WORLDWIDE engines need cooling — could it be done with one radiator, eliminating approximately US$75 000 in capital cost for an engine this size? The an- swer is yes. This was accomplished with an intermediate heat exchanger to optimize the return temperature to the engine and a bypass to ensure the engine cooling remained operating even when the ORC is not running. The impact to the overall installed cost for an ORC can now be reduced by 20 to 30%.” ElectraTherm said it currently man- ufactures a 35 kW unit (3600 model) that fits with 500 kW gen-sets, and a 65 kW unit (4400 model) that fits with 800 kW engines. The company’s project with the DOD is the first 110 kW unit (6500 model), and is well suited for 1 to 2 MW engines. “Our gen-set integration has been very successful,” Fox said. “Applica- tions include single and multiple en- gines utilizing jacket water heat alone as well as jacket water combined with exhaust heat. We have integrated into engines models such as Jenbacher, Deutz and MWM engines in Europe, as well as Cat and Waukesha engines in North America. “As we deploy our units in varied global applications, we are discovering new opportunities. We have looked at the large number of stationary engines associated with natural gas compres- sion, where engine heat is typically unused. A prospective customer is in- vestigating the potential to remove the shaft-driven radiators from their exist- ing gas compression engines, which would enable usage of approximately 56 kW of parasitic load from the en- gine and allow more power for addi- tional compression. Also, the ORC- generated electricity can be converted to use more compression via an electric compressor. More compression means more gas throughput, which equates to increased revenue. Particularly in emissions-capped areas where another engine cannot be easily added, this is a great way to increase plant throughput without additional emissions, thereby keeping the station under existing per- mitted levels.” Fox said that distributed WHP sys- tems for stationary engines are not yet well known or mainstream, but the technology is field proven and the economics are now attractive. “Our various packaged solutions are mak- ing it easier to economically capture waste heat and make emissions-free and fuel-free power from sources that already exist,” Fox said. “We are ex- cited about the introduction of the radiator with a payback.” A Copyright Diesel & Gas Turbine Publications Printed in U.S.A.PDF Image | DOD-funded ORC integration and replacement project

PDF Search Title:

DOD-funded ORC integration and replacement projectOriginal File Name Searched:

DGTW_reprint___Electratherm.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |