PDF Publication Title:

Text from PDF Page: 001

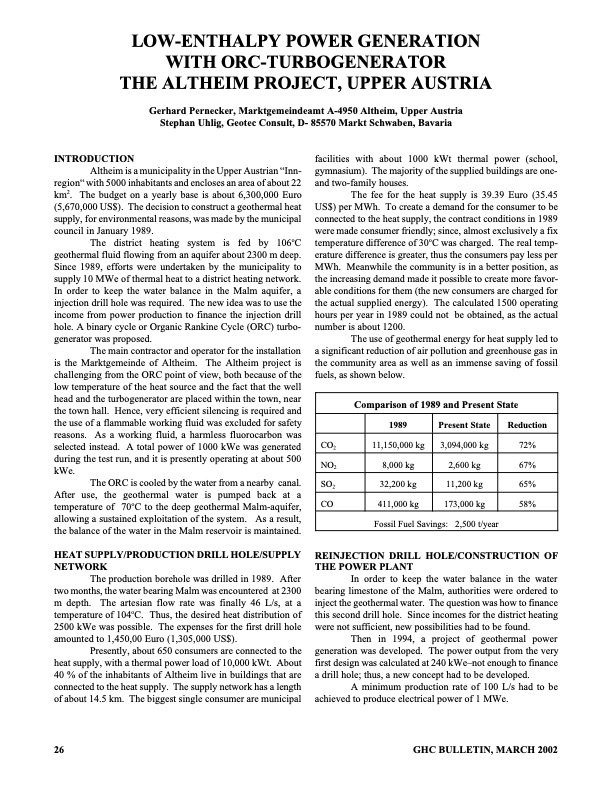

LOW-ENTHALPY POWER GENERATION WITH ORC-TURBOGENERATOR THE ALTHEIM PROJECT, UPPER AUSTRIA Gerhard Pernecker, Marktgemeindeamt A-4950 Altheim, Upper Austria Stephan Uhlig, Geotec Consult, D- 85570 Markt Schwaben, Bavaria INTRODUCTION Altheim is a municipality in the Upper Austrian “Inn- region“ with 5000 inhabitants and encloses an area of about 22 km2. The budget on a yearly base is about 6,300,000 Euro (5,670,000 US$). The decision to construct a geothermal heat supply, for environmental reasons, was made by the municipal council in January 1989. The district heating system is fed by 106oC geothermal fluid flowing from an aquifer about 2300 m deep. Since 1989, efforts were undertaken by the municipality to supply 10 MWe of thermal heat to a district heating network. In order to keep the water balance in the Malm aquifer, a injection drill hole was required. The new idea was to use the income from power production to finance the injection drill hole. A binary cycle or Organic Rankine Cycle (ORC) turbo- generator was proposed. The main contractor and operator for the installation is the Marktgemeinde of Altheim. The Altheim project is challenging from the ORC point of view, both because of the low temperature of the heat source and the fact that the well head and the turbogenerator are placed within the town, near the town hall. Hence, very efficient silencing is required and the use of a flammable working fluid was excluded for safety reasons. As a working fluid, a harmless fluorocarbon was selected instead. A total power of 1000 kWe was generated during the test run, and it is presently operating at about 500 kWe. The ORC is cooled by the water from a nearby canal. After use, the geothermal water is pumped back at a temperature of 70oC to the deep geothermal Malm-aquifer, allowing a sustained exploitation of the system. As a result, the balance of the water in the Malm reservoir is maintained. HEAT SUPPLY/PRODUCTION DRILL HOLE/SUPPLY NETWORK The production borehole was drilled in 1989. After two months, the water bearing Malm was encountered at 2300 m depth. The artesian flow rate was finally 46 L/s, at a temperature of 104oC. Thus, the desired heat distribution of 2500 kWe was possible. The expenses for the first drill hole amounted to 1,450,00 Euro (1,305,000 US$). Presently, about 650 consumers are connected to the heat supply, with a thermal power load of 10,000 kWt. About 40 % of the inhabitants of Altheim live in buildings that are connected to the heat supply. The supply network has a length of about 14.5 km. The biggest single consumer are municipal facilities with about 1000 kWt thermal power (school, gymnasium). The majority of the supplied buildings are one- and two-family houses. The fee for the heat supply is 39.39 Euro (35.45 US$) per MWh. To create a demand for the consumer to be connected to the heat supply, the contract conditions in 1989 were made consumer friendly; since, almost exclusively a fix temperature difference of 30oC was charged. The real temp- erature difference is greater, thus the consumers pay less per MWh. Meanwhile the community is in a better position, as the increasing demand made it possible to create more favor- able conditions for them (the new consumers are charged for the actual supplied energy). The calculated 1500 operating hours per year in 1989 could not be obtained, as the actual number is about 1200. The use of geothermal energy for heat supply led to a significant reduction of air pollution and greenhouse gas in the community area as well as an immense saving of fossil fuels, as shown below. Comparison of 1989 and Present State CO2 NO2 SO2 CO 3,094,000 kg 72% 2,600 kg 67% 11,200 kg 65% 173,000 kg 58% 1989 11,150,000 kg 8,000 kg 32,200 kg 411,000 kg Present State Reduction Fossil Fuel Savings: 2,500 t/year 26 GHC BULLETIN, MARCH 2002 REINJECTION DRILL HOLE/CONSTRUCTION OF THE POWER PLANT In order to keep the water balance in the water bearing limestone of the Malm, authorities were ordered to inject the geothermal water. The question was how to finance this second drill hole. Since incomes for the district heating were not sufficient, new possibilities had to be found. Then in 1994, a project of geothermal power generation was developed. The power output from the very first design was calculated at 240 kWe–not enough to finance a drill hole; thus, a new concept had to be developed. A minimum production rate of 100 L/s had to be achieved to produce electrical power of 1 MWe.PDF Image | LOW-ENTHALPY POWER GENERATION WITH ORC-TURBOGENERATOR

PDF Search Title:

LOW-ENTHALPY POWER GENERATION WITH ORC-TURBOGENERATOROriginal File Name Searched:

art6.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |