PDF Publication Title:

Text from PDF Page: 003

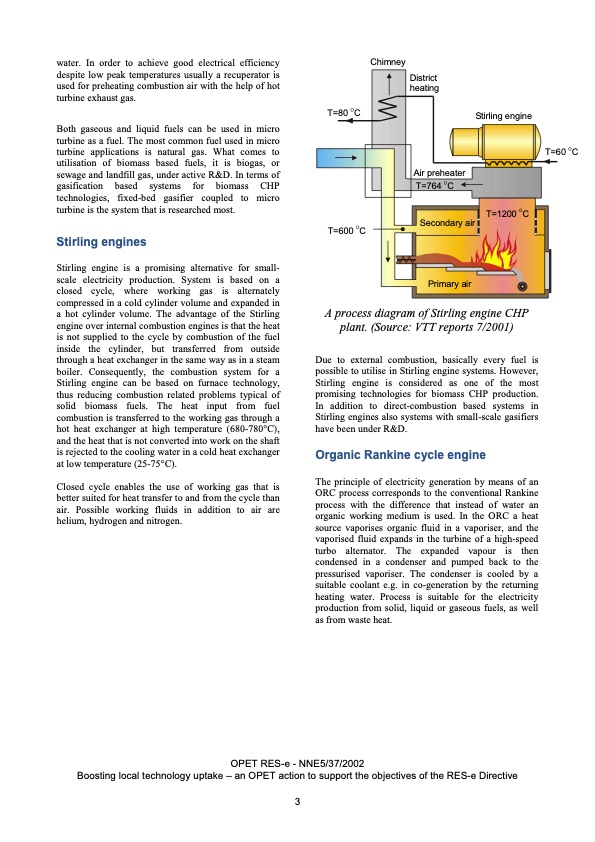

water. In order to achieve good electrical efficiency despite low peak temperatures usually a recuperator is used for preheating combustion air with the help of hot turbine exhaust gas. Both gaseous and liquid fuels can be used in micro turbine as a fuel. The most common fuel used in micro turbine applications is natural gas. What comes to utilisation of biomass based fuels, it is biogas, or sewage and landfill gas, under active R&D. In terms of gasification based systems for biomass CHP technologies, fixed-bed gasifier coupled to micro turbine is the system that is researched most. Stirling engines Stirling engine is a promising alternative for small- scale electricity production. System is based on a closed cycle, where working gas is alternately compressed in a cold cylinder volume and expanded in a hot cylinder volume. The advantage of the Stirling engine over internal combustion engines is that the heat is not supplied to the cycle by combustion of the fuel inside the cylinder, but transferred from outside through a heat exchanger in the same way as in a steam boiler. Consequently, the combustion system for a Stirling engine can be based on furnace technology, thus reducing combustion related problems typical of solid biomass fuels. The heat input from fuel combustion is transferred to the working gas through a hot heat exchanger at high temperature (680-780°C), and the heat that is not converted into work on the shaft is rejected to the cooling water in a cold heat exchanger at low temperature (25-75°C). Closed cycle enables the use of working gas that is better suited for heat transfer to and from the cycle than air. Possible working fluids in addition to air are helium, hydrogen and nitrogen. Chimney T=80 OC T=600 OC District heating Air preheater T=764 OC Stirling engine T=60 OC T=1200 OC Secondary air Primary air OPET RES-e - NNE5/37/2002 Boosting local technology uptake – an OPET action to support the objectives of the RES-e Directive 3 A process diagram of Stirling engine CHP plant. (Source: VTT reports 7/2001) Due to external combustion, basically every fuel is possible to utilise in Stirling engine systems. However, Stirling engine is considered as one of the most promising technologies for biomass CHP production. In addition to direct-combustion based systems in Stirling engines also systems with small-scale gasifiers have been under R&D. Organic Rankine cycle engine The principle of electricity generation by means of an ORC process corresponds to the conventional Rankine process with the difference that instead of water an organic working medium is used. In the ORC a heat source vaporises organic fluid in a vaporiser, and the vaporised fluid expands in the turbine of a high-speed turbo alternator. The expanded vapour is then condensed in a condenser and pumped back to the pressurised vaporiser. The condenser is cooled by a suitable coolant e.g. in co-generation by the returning heating water. Process is suitable for the electricity production from solid, liquid or gaseous fuels, as well as from waste heat.PDF Image | Micro and small-scale CHP from biomass less than 300 kWe

PDF Search Title:

Micro and small-scale CHP from biomass less than 300 kWeOriginal File Name Searched:

20041021033834.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |