PDF Publication Title:

Text from PDF Page: 003

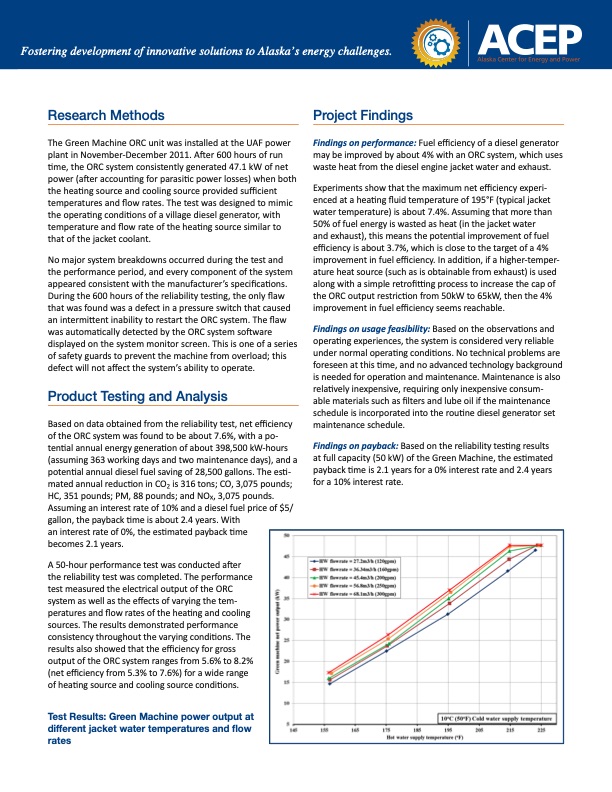

Fostering development of innovative solutions to Alaska’s energy challenges. Research Methods The Green Machine ORC unit was installed at the UAF power plant in November-December 2011. After 600 hours of run time, the ORC system consistently generated 47.1 kW of net power (after accounting for parasitic power losses) when both the heating source and cooling source provided sufficient temperatures and flow rates. The test was designed to mimic the operating conditions of a village diesel generator, with temperature and flow rate of the heating source similar to that of the jacket coolant. No major system breakdowns occurred during the test and the performance period, and every component of the system appeared consistent with the manufacturer’s specifications. During the 600 hours of the reliability testing, the only flaw that was found was a defect in a pressure switch that caused an intermittent inability to restart the ORC system. The flaw was automatically detected by the ORC system software displayed on the system monitor screen. This is one of a series of safety guards to prevent the machine from overload; this defect will not affect the system’s ability to operate. Product Testing and Analysis Based on data obtained from the reliability test, net efficiency of the ORC system was found to be about 7.6%, with a po- tential annual energy generation of about 398,500 kW-hours (assuming 363 working days and two maintenance days), and a potential annual diesel fuel saving of 28,500 gallons. The esti- mated annual reduction in CO2 is 316 tons; CO, 3,075 pounds; HC, 351 pounds; PM, 88 pounds; and NOx, 3,075 pounds. Assuming an interest rate of 10% and a diesel fuel price of $5/ gallon, the payback time is about 2.4 years. With an interest rate of 0%, the estimated payback time becomes 2.1 years. A 50-hour performance test was conducted after the reliability test was completed. The performance test measured the electrical output of the ORC system as well as the effects of varying the tem- peratures and flow rates of the heating and cooling sources. The results demonstrated performance consistency throughout the varying conditions. The results also showed that the efficiency for gross output of the ORC system ranges from 5.6% to 8.2% (net efficiency from 5.3% to 7.6%) for a wide range of heating source and cooling source conditions. Test Results: Green Machine power output at different jacket water temperatures and flow rates Project Findings Findings on performance: Fuel efficiency of a diesel generator may be improved by about 4% with an ORC system, which uses waste heat from the diesel engine jacket water and exhaust. Experiments show that the maximum net efficiency experi- enced at a heating fluid temperature of 195°F (typical jacket water temperature) is about 7.4%. Assuming that more than 50% of fuel energy is wasted as heat (in the jacket water and exhaust), this means the potential improvement of fuel efficiency is about 3.7%, which is close to the target of a 4% improvement in fuel efficiency. In addition, if a higher-temper- ature heat source (such as is obtainable from exhaust) is used along with a simple retrofitting process to increase the cap of the ORC output restriction from 50kW to 65kW, then the 4% improvement in fuel efficiency seems reachable. Findings on usage feasibility: Based on the observations and operating experiences, the system is considered very reliable under normal operating conditions. No technical problems are foreseen at this time, and no advanced technology background is needed for operation and maintenance. Maintenance is also relatively inexpensive, requiring only inexpensive consum- able materials such as filters and lube oil if the maintenance schedule is incorporated into the routine diesel generator set maintenance schedule. Findings on payback: Based on the reliability testing results at full capacity (50 kW) of the Green Machine, the estimated payback time is 2.1 years for a 0% interest rate and 2.4 years for a 10% interest rate.PDF Image | Means for Increasing Diesel Engine Efficiency in Alaska

PDF Search Title:

Means for Increasing Diesel Engine Efficiency in AlaskaOriginal File Name Searched:

ACEP_ORC_Research_Briefing_4_23_13.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |