PDF Publication Title:

Text from PDF Page: 008

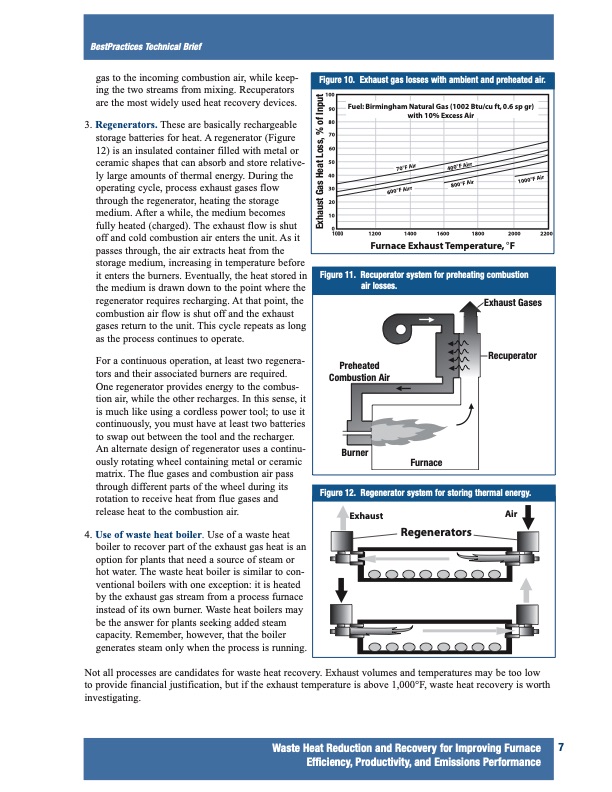

BestPractices Technical Brief Figure 10. Exhaust gas losses with ambient and preheated air. 100 90 80 70 60 50 40 30 20 10 0 1000 1200 1400 1600 1800 2000 2200 Fuel: Birmingham Natural Gas (1002 Btu/cu ft, 0.6 with 10% Excess Air Furnace Exhaust Temperature, °F sp gr) gas to the incoming combustion air, while keep- ing the two streams from mixing. Recuperators are the most widely used heat recovery devices. 3. Regenerators. These are basically rechargeable storage batteries for heat. A regenerator (Figure 12) is an insulated container filled with metal or ceramic shapes that can absorb and store relative- ly large amounts of thermal energy. During the operating cycle, process exhaust gases flow through the regenerator, heating the storage medium. After a while, the medium becomes fully heated (charged). The exhaust flow is shut off and cold combustion air enters the unit. As it passes through, the air extracts heat from the storage medium, increasing in temperature before it enters the burners. Eventually, the heat stored in the medium is drawn down to the point where the regenerator requires recharging. At that point, the combustion air flow is shut off and the exhaust gases return to the unit. This cycle repeats as long as the process continues to operate. For a continuous operation, at least two regenera- tors and their associated burners are required. One regenerator provides energy to the combus- tion air, while the other recharges. In this sense, it is much like using a cordless power tool; to use it continuously, you must have at least two batteries to swap out between the tool and the recharger. An alternate design of regenerator uses a continu- ously rotating wheel containing metal or ceramic matrix. The flue gases and combustion air pass through different parts of the wheel during its rotation to receive heat from flue gases and release heat to the combustion air. 4. Use of waste heat boiler. Use of a waste heat boiler to recover part of the exhaust gas heat is an option for plants that need a source of steam or hot water. The waste heat boiler is similar to con- ventional boilers with one exception: it is heated by the exhaust gas stream from a process furnace instead of its own burner. Waste heat boilers may be the answer for plants seeking added steam capacity. Remember, however, that the boiler generates steam only when the process is running. Not all processes are candidates for waste heat recovery. Exhaust volumes and temperatures may be too low to provide financial justification, but if the exhaust temperature is above 1,000°F, waste heat recovery is worth investigating. Waste Heat Reduction and Recovery for Improving Furnace 7 Efficiency, Productivity, and Emissions Performance Figure 11. Recuperator system for preheating combustion air losses. Exhaust Gases Recuperator Preheated Combustion Air Burner Furnace Figure 12. Regenerator system for storing thermal energy. Exhaust Air Regenerators Exhaust Gas Heat Loss, % of Input 400°F Airr 70°F Air 800°F Air 1000°F Air 600°F AirrPDF Image | Waste Heat Reduction and Recovery for Improving Furnace Efficiency, Productivity and Emissions Performance

PDF Search Title:

Waste Heat Reduction and Recovery for Improving Furnace Efficiency, Productivity and Emissions PerformanceOriginal File Name Searched:

35876.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |