PDF Publication Title:

Text from PDF Page: 006

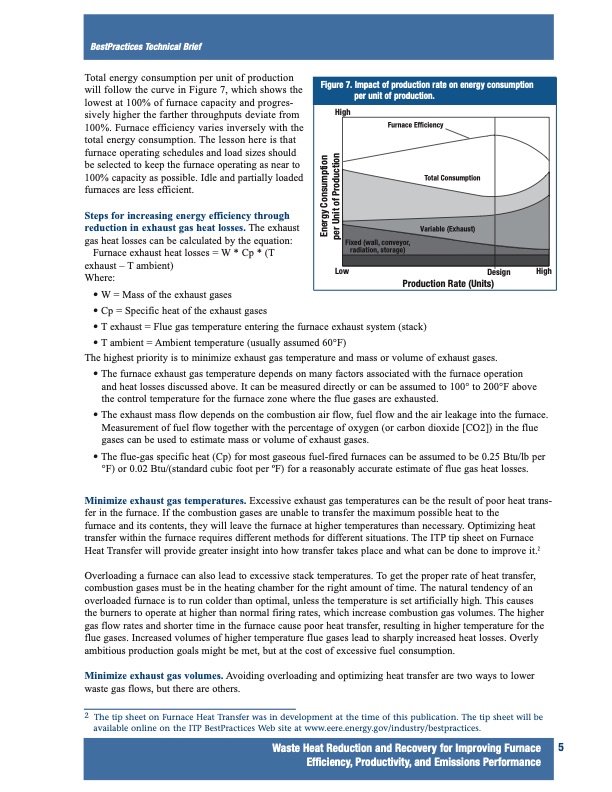

BestPractices Technical Brief Total energy consumption per unit of production will follow the curve in Figure 7, which shows the lowest at 100% of furnace capacity and progres- sively higher the farther throughputs deviate from 100%. Furnace efficiency varies inversely with the total energy consumption. The lesson here is that furnace operating schedules and load sizes should be selected to keep the furnace operating as near to 100% capacity as possible. Idle and partially loaded furnaces are less efficient. Steps for increasing energy efficiency through reduction in exhaust gas heat losses. The exhaust gas heat losses can be calculated by the equation: Furnace exhaust heat losses = W * Cp * (T exhaust – T ambient) Where: • W = Mass of the exhaust gases • Cp = Specific heat of the exhaust gases • T exhaust = Flue gas temperature entering the furnace exhaust system (stack) • T ambient = Ambient temperature (usually assumed 60°F) The highest priority is to minimize exhaust gas temperature and mass or volume of exhaust gases. • The furnace exhaust gas temperature depends on many factors associated with the furnace operation and heat losses discussed above. It can be measured directly or can be assumed to 100° to 200°F above the control temperature for the furnace zone where the flue gases are exhausted. • The exhaust mass flow depends on the combustion air flow, fuel flow and the air leakage into the furnace. Measurement of fuel flow together with the percentage of oxygen (or carbon dioxide [CO2]) in the flue gases can be used to estimate mass or volume of exhaust gases. • The flue-gas specific heat (Cp) for most gaseous fuel-fired furnaces can be assumed to be 0.25 Btu/lb per °F) or 0.02 Btu/(standard cubic foot per oF) for a reasonably accurate estimate of flue gas heat losses. Minimize exhaust gas temperatures. Excessive exhaust gas temperatures can be the result of poor heat trans- fer in the furnace. If the combustion gases are unable to transfer the maximum possible heat to the furnace and its contents, they will leave the furnace at higher temperatures than necessary. Optimizing heat transfer within the furnace requires different methods for different situations. The ITP tip sheet on Furnace Heat Transfer will provide greater insight into how transfer takes place and what can be done to improve it.2 Overloading a furnace can also lead to excessive stack temperatures. To get the proper rate of heat transfer, combustion gases must be in the heating chamber for the right amount of time. The natural tendency of an overloaded furnace is to run colder than optimal, unless the temperature is set artificially high. This causes the burners to operate at higher than normal firing rates, which increase combustion gas volumes. The higher gas flow rates and shorter time in the furnace cause poor heat transfer, resulting in higher temperature for the flue gases. Increased volumes of higher temperature flue gases lead to sharply increased heat losses. Overly ambitious production goals might be met, but at the cost of excessive fuel consumption. Minimize exhaust gas volumes. Avoiding overloading and optimizing heat transfer are two ways to lower waste gas flows, but there are others. Figure 7. Impact of production rate on energy consumption per unit of production. High Fixed (wall, conveyor, radiation, storage) Furnace Efficiency Total Consumption Variable (Exhaust) Low Design High Production Rate (Units) 2 The tip sheet on Furnace Heat Transfer was in development at the time of this publication. The tip sheet will be available online on the ITP BestPractices Web site at www.eere.energy.gov/industry/bestpractices. Waste Heat Reduction and Recovery for Improving Furnace Efficiency, Productivity, and Emissions Performance 5 Energy Consumption per Unit of ProductionPDF Image | Waste Heat Reduction and Recovery for Improving Furnace Efficiency, Productivity and Emissions Performance

PDF Search Title:

Waste Heat Reduction and Recovery for Improving Furnace Efficiency, Productivity and Emissions PerformanceOriginal File Name Searched:

35876.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |