PDF Publication Title:

Text from PDF Page: 003

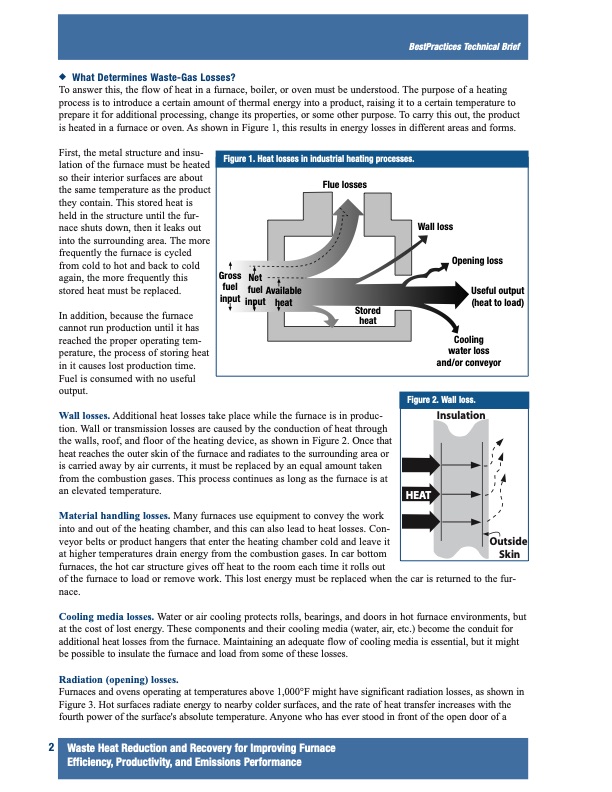

N What Determines Waste-Gas Losses? To answer this, the flow of heat in a furnace, boiler, or oven must be understood. The purpose of a heating process is to introduce a certain amount of thermal energy into a product, raising it to a certain temperature to prepare it for additional processing, change its properties, or some other purpose. To carry this out, the product is heated in a furnace or oven. As shown in Figure 1, this results in energy losses in different areas and forms. First, the metal structure and insu- lation of the furnace must be heated so their interior surfaces are about the same temperature as the product they contain. This stored heat is held in the structure until the fur- nace shuts down, then it leaks out into the surrounding area. The more frequently the furnace is cycled from cold to hot and back to cold again, the more frequently this stored heat must be replaced. In addition, because the furnace cannot run production until it has reached the proper operating tem- perature, the process of storing heat in it causes lost production time. Fuel is consumed with no useful output. Wall losses. Additional heat losses take place while the furnace is in produc- tion. Wall or transmission losses are caused by the conduction of heat through the walls, roof, and floor of the heating device, as shown in Figure 2. Once that heat reaches the outer skin of the furnace and radiates to the surrounding area or is carried away by air currents, it must be replaced by an equal amount taken from the combustion gases. This process continues as long as the furnace is at an elevated temperature. Material handling losses. Many furnaces use equipment to convey the work into and out of the heating chamber, and this can also lead to heat losses. Con- veyor belts or product hangers that enter the heating chamber cold and leave it at higher temperatures drain energy from the combustion gases. In car bottom furnaces, the hot car structure gives off heat to the room each time it rolls out of the furnace to load or remove work. This lost energy must be replaced when the car is returned to the fur- nace. Cooling media losses. Water or air cooling protects rolls, bearings, and doors in hot furnace environments, but at the cost of lost energy. These components and their cooling media (water, air, etc.) become the conduit for additional heat losses from the furnace. Maintaining an adequate flow of cooling media is essential, but it might be possible to insulate the furnace and load from some of these losses. Radiation (opening) losses. Furnaces and ovens operating at temperatures above 1,000°F might have significant radiation losses, as shown in Figure 3. Hot surfaces radiate energy to nearby colder surfaces, and the rate of heat transfer increases with the fourth power of the surface's absolute temperature. Anyone who has ever stood in front of the open door of a Figure 1. Heat losses in industrial heating processes. Gross Net Flue losses Stored heat Wall loss Opening loss Useful output (heat to load) Cooling water loss and/or conveyor fuel input input fuel Available heat Figure 2. Wall loss. HEAT Insulation Outside Skin 2 BestPractices Technical Brief Waste Heat Reduction and Recovery for Improving Furnace Efficiency, Productivity, and Emissions PerformancePDF Image | Waste Heat Reduction and Recovery for Improving Furnace Efficiency, Productivity and Emissions Performance

PDF Search Title:

Waste Heat Reduction and Recovery for Improving Furnace Efficiency, Productivity and Emissions PerformanceOriginal File Name Searched:

35876.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |