PDF Publication Title:

Text from PDF Page: 011

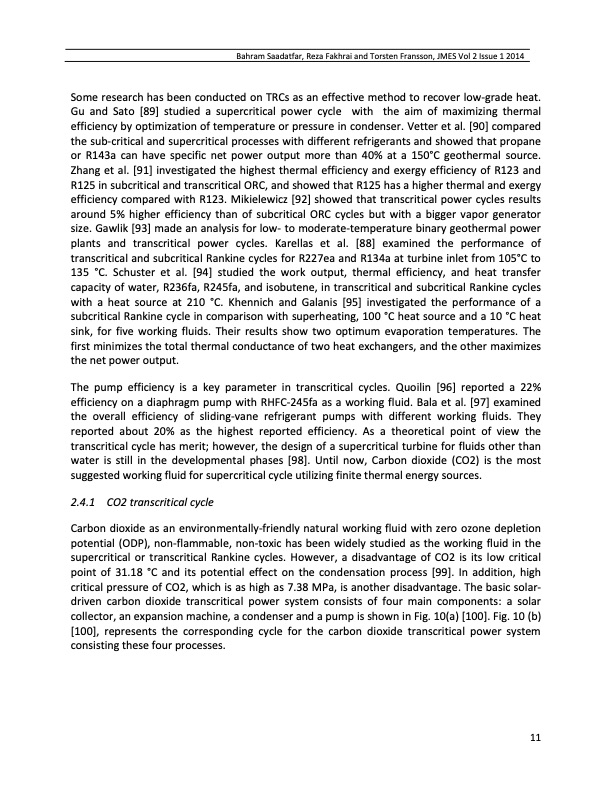

Bahram Saadatfar, Reza Fakhrai and Torsten Fransson, JMES Vol 2 Issue 1 2014 Some research has been conducted on TRCs as an effective method to recover low-grade heat. Gu and Sato [89] studied a supercritical power cycle with the aim of maximizing thermal efficiency by optimization of temperature or pressure in condenser. Vetter et al. [90] compared the sub-critical and supercritical processes with different refrigerants and showed that propane or R143a can have specific net power output more than 40% at a 150°C geothermal source. Zhang et al. [91] investigated the highest thermal efficiency and exergy efficiency of R123 and R125 in subcritical and transcritical ORC, and showed that R125 has a higher thermal and exergy efficiency compared with R123. Mikielewicz [92] showed that transcritical power cycles results around 5% higher efficiency than of subcritical ORC cycles but with a bigger vapor generator size. Gawlik [93] made an analysis for low- to moderate-temperature binary geothermal power plants and transcritical power cycles. Karellas et al. [88] examined the performance of transcritical and subcritical Rankine cycles for R227ea and R134a at turbine inlet from 105°C to 135 °C. Schuster et al. [94] studied the work output, thermal efficiency, and heat transfer capacity of water, R236fa, R245fa, and isobutene, in transcritical and subcritical Rankine cycles with a heat source at 210 °C. Khennich and Galanis [95] investigated the performance of a subcritical Rankine cycle in comparison with superheating, 100 °C heat source and a 10 °C heat sink, for five working fluids. Their results show two optimum evaporation temperatures. The first minimizes the total thermal conductance of two heat exchangers, and the other maximizes the net power output. The pump efficiency is a key parameter in transcritical cycles. Quoilin [96] reported a 22% efficiency on a diaphragm pump with RHFC-245fa as a working fluid. Bala et al. [97] examined the overall efficiency of sliding-vane refrigerant pumps with different working fluids. They reported about 20% as the highest reported efficiency. As a theoretical point of view the transcritical cycle has merit; however, the design of a supercritical turbine for fluids other than water is still in the developmental phases [98]. Until now, Carbon dioxide (CO2) is the most suggested working fluid for supercritical cycle utilizing finite thermal energy sources. 2.4.1 CO2 transcritical cycle Carbon dioxide as an environmentally-friendly natural working fluid with zero ozone depletion potential (ODP), non-flammable, non-toxic has been widely studied as the working fluid in the supercritical or transcritical Rankine cycles. However, a disadvantage of CO2 is its low critical point of 31.18 °C and its potential effect on the condensation process [99]. In addition, high critical pressure of CO2, which is as high as 7.38 MPa, is another disadvantage. The basic solar- driven carbon dioxide transcritical power system consists of four main components: a solar collector, an expansion machine, a condenser and a pump is shown in Fig. 10(a) [100]. Fig. 10 (b) [100], represents the corresponding cycle for the carbon dioxide transcritical power system consisting these four processes. 11PDF Image | Thermodynamic Vapor Cycles for Converting Low- to Medium-grade Heat to Power: A State-of-the- art Review and Future Research Pathways

PDF Search Title:

Thermodynamic Vapor Cycles for Converting Low- to Medium-grade Heat to Power: A State-of-the- art Review and Future Research PathwaysOriginal File Name Searched:

1ES21Ba.89125232.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |