PDF Publication Title:

Text from PDF Page: 003

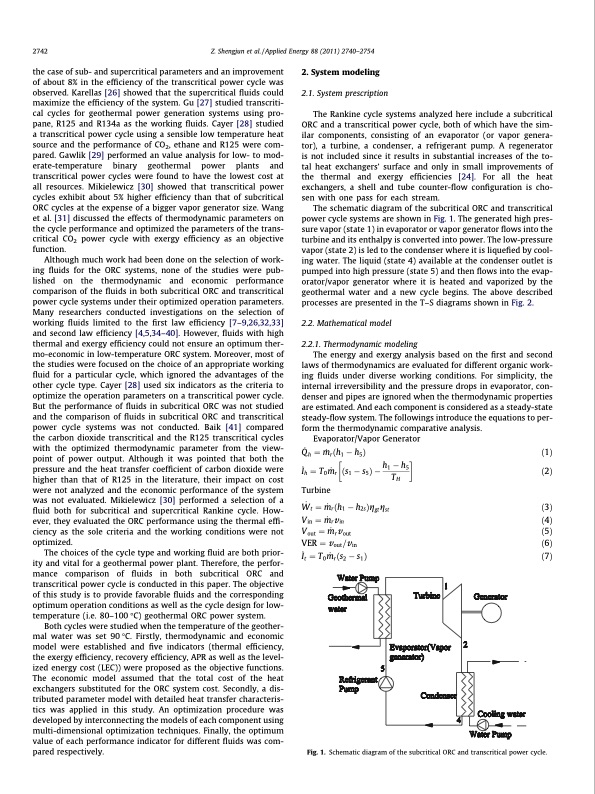

2742 Z. Shengjun et al. / Applied Energy 88 (2011) 2740–2754 the case of sub- and supercritical parameters and an improvement of about 8% in the efficiency of the transcritical power cycle was observed. Karellas [26] showed that the supercritical fluids could maximize the efficiency of the system. Gu [27] studied transcriti- cal cycles for geothermal power generation systems using pro- pane, R125 and R134a as the working fluids. Cayer [28] studied a transcritical power cycle using a sensible low temperature heat source and the performance of CO2, ethane and R125 were com- pared. Gawlik [29] performed an value analysis for low- to mod- erate-temperature binary geothermal power plants and transcritical power cycles were found to have the lowest cost at all resources. Mikielewicz [30] showed that transcritical power cycles exhibit about 5% higher efficiency than that of subcritical ORC cycles at the expense of a bigger vapor generator size. Wang et al. [31] discussed the effects of thermodynamic parameters on the cycle performance and optimized the parameters of the trans- critical CO2 power cycle with exergy efficiency as an objective function. Although much work had been done on the selection of work- ing fluids for the ORC systems, none of the studies were pub- lished on the thermodynamic and economic performance comparison of the fluids in both subcritical ORC and transcritical power cycle systems under their optimized operation parameters. Many researchers conducted investigations on the selection of working fluids limited to the first law efficiency [7–9,26,32,33] and second law efficiency [4,5,34–40]. However, fluids with high thermal and exergy efficiency could not ensure an optimum ther- mo-economic in low-temperature ORC system. Moreover, most of the studies were focused on the choice of an appropriate working fluid for a particular cycle, which ignored the advantages of the other cycle type. Cayer [28] used six indicators as the criteria to optimize the operation parameters on a transcritical power cycle. But the performance of fluids in subcritical ORC was not studied and the comparison of fluids in subcritical ORC and transcritical power cycle systems was not conducted. Baik [41] compared the carbon dioxide transcritical and the R125 transcritical cycles with the optimized thermodynamic parameter from the view- point of power output. Although it was pointed that both the pressure and the heat transfer coefficient of carbon dioxide were higher than that of R125 in the literature, their impact on cost were not analyzed and the economic performance of the system was not evaluated. Mikielewicz [30] performed a selection of a fluid both for subcritical and supercritical Rankine cycle. How- ever, they evaluated the ORC performance using the thermal effi- ciency as the sole criteria and the working conditions were not optimized. The choices of the cycle type and working fluid are both prior- ity and vital for a geothermal power plant. Therefore, the perfor- mance comparison of fluids in both subcritical ORC and transcritical power cycle is conducted in this paper. The objective of this study is to provide favorable fluids and the corresponding optimum operation conditions as well as the cycle design for low- temperature (i.e. 80–100 °C) geothermal ORC power system. Both cycles were studied when the temperature of the geother- mal water was set 90 °C. Firstly, thermodynamic and economic model were established and five indicators (thermal efficiency, the exergy efficiency, recovery efficiency, APR as well as the level- ized energy cost (LEC)) were proposed as the objective functions. The economic model assumed that the total cost of the heat exchangers substituted for the ORC system cost. Secondly, a dis- tributed parameter model with detailed heat transfer characteris- tics was applied in this study. An optimization procedure was developed by interconnecting the models of each component using multi-dimensional optimization techniques. Finally, the optimum value of each performance indicator for different fluids was com- pared respectively. 2. System modeling 2.1. System prescription The Rankine cycle systems analyzed here include a subcritical ORC and a transcritical power cycle, both of which have the sim- ilar components, consisting of an evaporator (or vapor genera- tor), a turbine, a condenser, a refrigerant pump. A regenerator is not included since it results in substantial increases of the to- tal heat exchangers’ surface and only in small improvements of the thermal and exergy efficiencies [24]. For all the heat exchangers, a shell and tube counter-flow configuration is cho- sen with one pass for each stream. The schematic diagram of the subcritical ORC and transcritical power cycle systems are shown in Fig. 1. The generated high pres- sure vapor (state 1) in evaporator or vapor generator flows into the turbine and its enthalpy is converted into power. The low-pressure vapor (state 2) is led to the condenser where it is liquefied by cool- ing water. The liquid (state 4) available at the condenser outlet is pumped into high pressure (state 5) and then flows into the evap- orator/vapor generator where it is heated and vaporized by the geothermal water and a new cycle begins. The above described processes are presented in the T–S diagrams shown in Fig. 2. 2.2. Mathematical model 2.2.1. Thermodynamic modeling The energy and exergy analysis based on the first and second laws of thermodynamics are evaluated for different organic work- ing fluids under diverse working conditions. For simplicity, the internal irreversibility and the pressure drops in evaporator, con- denser and pipes are ignored when the thermodynamic properties are estimated. And each component is considered as a steady-state steady-flow system. The followings introduce the equations to per- form the thermodynamic comparative analysis. Evaporator/Vapor Generator Q_h1⁄4m_rðh1h5Þ ð1Þ ð2Þ ð3Þ ð4Þ ð5Þ ð6Þ ð7Þ h1 h5 I_h1⁄4T0m_rðs1s5ÞT Turbine H W_t1⁄4m_rðh1h2sÞggtgst Vin1⁄4m_rvin Vout1⁄4m_rvout VER 1⁄4 vout=vin I_t1⁄4T0m_rðs2s1Þ Fig. 1. Schematic diagram of the subcritical ORC and transcritical power cycle.PDF Image | Performance comparison and parametric optimization of subcritical Organic Rankine Cycle (ORC) and transcritical power cycle system for low-temperature geothermal power generation

PDF Search Title:

Performance comparison and parametric optimization of subcritical Organic Rankine Cycle (ORC) and transcritical power cycle system for low-temperature geothermal power generationOriginal File Name Searched:

2011___S._Zang___Performance_comparison_and_parametric_optimization_of_subcritical_and_transcritical.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |