PDF Publication Title:

Text from PDF Page: 003

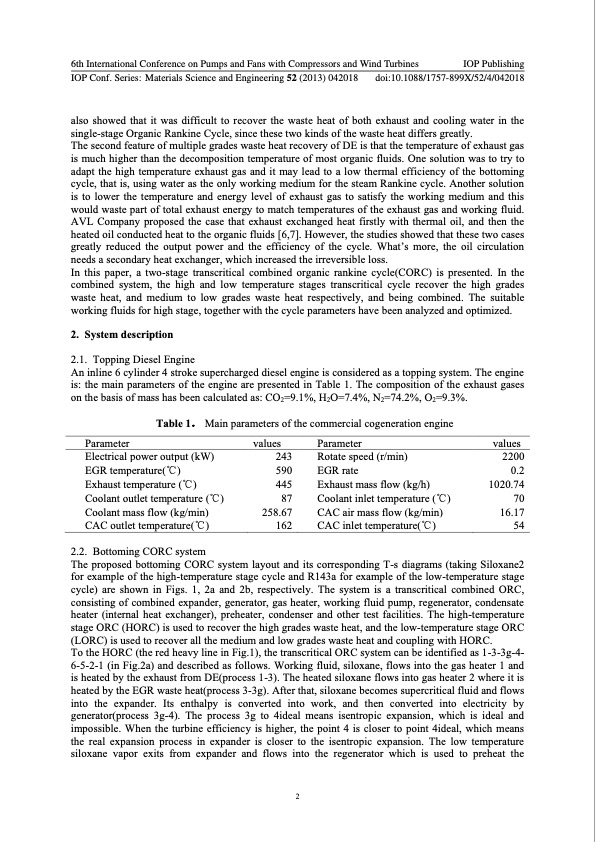

6th International Conference on Pumps and Fans with Compressors and Wind Turbines IOP Publishing IOP Conf. Series: Materials Science and Engineering 52 (2013) 042018 doi:10.1088/1757-899X/52/4/042018 also showed that it was difficult to recover the waste heat of both exhaust and cooling water in the single-stage Organic Rankine Cycle, since these two kinds of the waste heat differs greatly. The second feature of multiple grades waste heat recovery of DE is that the temperature of exhaust gas is much higher than the decomposition temperature of most organic fluids. One solution was to try to adapt the high temperature exhaust gas and it may lead to a low thermal efficiency of the bottoming cycle, that is, using water as the only working medium for the steam Rankine cycle. Another solution is to lower the temperature and energy level of exhaust gas to satisfy the working medium and this would waste part of total exhaust energy to match temperatures of the exhaust gas and working fluid. AVL Company proposed the case that exhaust exchanged heat firstly with thermal oil, and then the heated oil conducted heat to the organic fluids [6,7]. However, the studies showed that these two cases greatly reduced the output power and the efficiency of the cycle. What’s more, the oil circulation needs a secondary heat exchanger, which increased the irreversible loss. In this paper, a two-stage transcritical combined organic rankine cycle(CORC) is presented. In the combined system, the high and low temperature stages transcritical cycle recover the high grades waste heat, and medium to low grades waste heat respectively, and being combined. The suitable working fluids for high stage, together with the cycle parameters have been analyzed and optimized. 2. System description 2.1. Topping Diesel Engine An inline 6 cylinder 4 stroke supercharged diesel engine is considered as a topping system. The engine is: the main parameters of the engine are presented in Table 1. The composition of the exhaust gases on the basis of mass has been calculated as: CO2=9.1%, H2O=7.4%, N2=74.2%, O2=9.3%. Table 1. Main parameters of the commercial cogeneration engine Parameter Electrical power output (kW) EGR temperature(°C) Exhaust temperature (°C) Coolant outlet temperature (°C) Coolant mass flow (kg/min) CAC outlet temperature(°C) 2.2. Bottoming CORC system values Parameter values 243 Rotate speed (r/min) 2200 590 EGR rate 0.2 445 Exhaust mass flow (kg/h) 1020.74 87 Coolant inlet temperature (°C) 70 258.67 CAC air mass flow (kg/min) 16.17 162 CAC inlet temperature(°C) 54 The proposed bottoming CORC system layout and its corresponding T-s diagrams (taking Siloxane2 for example of the high-temperature stage cycle and R143a for example of the low-temperature stage cycle) are shown in Figs. 1, 2a and 2b, respectively. The system is a transcritical combined ORC, consisting of combined expander, generator, gas heater, working fluid pump, regenerator, condensate heater (internal heat exchanger), preheater, condenser and other test facilities. The high-temperature stage ORC (HORC) is used to recover the high grades waste heat, and the low-temperature stage ORC (LORC) is used to recover all the medium and low grades waste heat and coupling with HORC. To the HORC (the red heavy line in Fig.1), the transcritical ORC system can be identified as 1-3-3g-4- 6-5-2-1 (in Fig.2a) and described as follows. Working fluid, siloxane, flows into the gas heater 1 and is heated by the exhaust from DE(process 1-3). The heated siloxane flows into gas heater 2 where it is heated by the EGR waste heat(process 3-3g). After that, siloxane becomes supercritical fluid and flows into the expander. Its enthalpy is converted into work, and then converted into electricity by generator(process 3g-4). The process 3g to 4ideal means isentropic expansion, which is ideal and impossible. When the turbine efficiency is higher, the point 4 is closer to point 4ideal, which means the real expansion process in expander is closer to the isentropic expansion. The low temperature siloxane vapor exits from expander and flows into the regenerator which is used to preheat the 2PDF Image | Parametric and exergetic analysis of a two-stage transcritical combined organic Rankine cycle used for multiple grades waste heat recovery of diesel engine

PDF Search Title:

Parametric and exergetic analysis of a two-stage transcritical combined organic Rankine cycle used for multiple grades waste heat recovery of diesel engineOriginal File Name Searched:

1757_899X_52_4_042018.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |