PDF Publication Title:

Text from PDF Page: 002

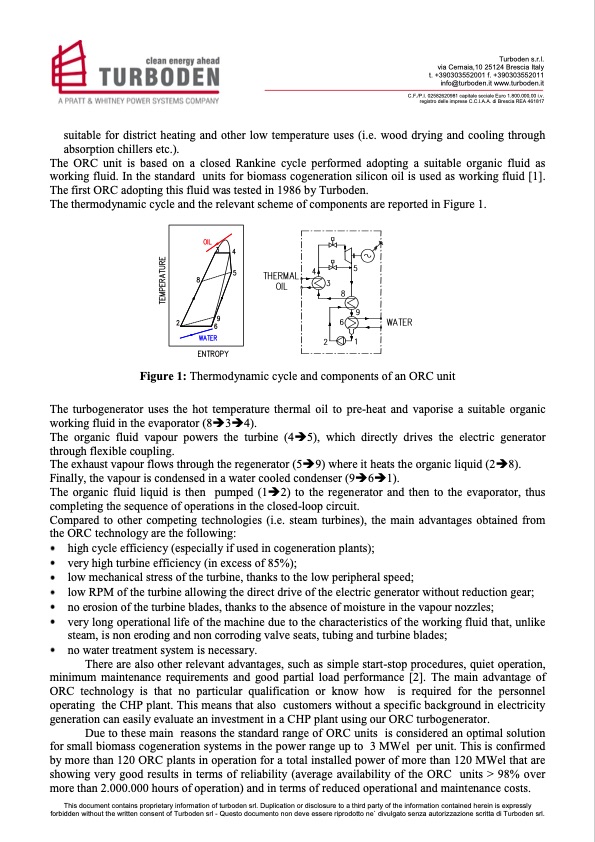

Turboden s.r.l. via Cernaia,10 25124 Brescia Italy t. +390303552001 f. +390303552011 info@turboden.it www.turboden.it C.F./P.I. 02582620981 capitale sociale Euro 1.800.000,00 i.v. registro delle imprese C.C.I.A.A. di Brescia REA 461817 suitable for district heating and other low temperature uses (i.e. wood drying and cooling through absorption chillers etc.). The ORC unit is based on a closed Rankine cycle performed adopting a suitable organic fluid as working fluid. In the standard units for biomass cogeneration silicon oil is used as working fluid [1]. The first ORC adopting this fluid was tested in 1986 by Turboden. The thermodynamic cycle and the relevant scheme of components are reported in Figure 1. Figure 1: Thermodynamic cycle and components of an ORC unit The turbogenerator uses the hot temperature thermal oil to pre-heat and vaporise a suitable organic working fluid in the evaporator (834). The organic fluid vapour powers the turbine (45), which directly drives the electric generator through flexible coupling. The exhaust vapour flows through the regenerator (59) where it heats the organic liquid (28). Finally, the vapour is condensed in a water cooled condenser (961). The organic fluid liquid is then pumped (12) to the regenerator and then to the evaporator, thus completing the sequence of operations in the closed-loop circuit. Compared to other competing technologies (i.e. steam turbines), the main advantages obtained from the ORC technology are the following: high cycle efficiency (especially if used in cogeneration plants); very high turbine efficiency (in excess of 85%); low mechanical stress of the turbine, thanks to the low peripheral speed; low RPM of the turbine allowing the direct drive of the electric generator without reduction gear; no erosion of the turbine blades, thanks to the absence of moisture in the vapour nozzles; very long operational life of the machine due to the characteristics of the working fluid that, unlike steam, is non eroding and non corroding valve seats, tubing and turbine blades; no water treatment system is necessary. There are also other relevant advantages, such as simple start-stop procedures, quiet operation, minimum maintenance requirements and good partial load performance [2]. The main advantage of ORC technology is that no particular qualification or know how is required for the personnel operating the CHP plant. This means that also customers without a specific background in electricity generation can easily evaluate an investment in a CHP plant using our ORC turbogenerator. Due to these main reasons the standard range of ORC units is considered an optimal solution for small biomass cogeneration systems in the power range up to 3 MWel per unit. This is confirmed by more than 120 ORC plants in operation for a total installed power of more than 120 MWel that are showing very good results in terms of reliability (average availability of the ORC units > 98% over more than 2.000.000 hours of operation) and in terms of reduced operational and maintenance costs. This document contains proprietary information of turboden srl. Duplication or disclosure to a third party of the information contained herein is expressly forbidden without the written consent of Turboden srl - Questo documento non deve essere riprodotto ne` divulgato senza autorizzazione scritta di Turboden srl.PDF Image | ORGANIC RANKINE CYCLE (ORC) IN BIOMASS PLANTS: AN OVERVIEW ON DIFFERENT APPLICATIONS

PDF Search Title:

ORGANIC RANKINE CYCLE (ORC) IN BIOMASS PLANTS: AN OVERVIEW ON DIFFERENT APPLICATIONSOriginal File Name Searched:

10A02943_paper_marco.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |