PDF Publication Title:

Text from PDF Page: 003

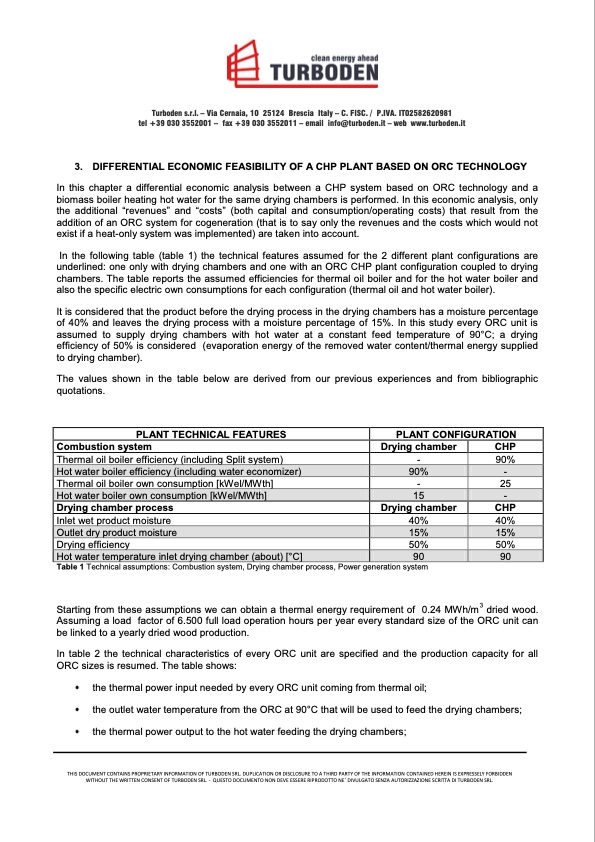

Turboden s.r.l. – Via Cernaia, 10 25124 Brescia Italy – C. FISC. / P.IVA. IT02582620981 tel +39 030 3552001 – fax +39 030 3552011 – email info@turboden.it – web www.turboden.it 3. DIFFERENTIAL ECONOMIC FEASIBILITY OF A CHP PLANT BASED ON ORC TECHNOLOGY In this chapter a differential economic analysis between a CHP system based on ORC technology and a biomass boiler heating hot water for the same drying chambers is performed. In this economic analysis, only the additional “revenues” and “costs” (both capital and consumption/operating costs) that result from the addition of an ORC system for cogeneration (that is to say only the revenues and the costs which would not exist if a heat-only system was implemented) are taken into account. In the following table (table 1) the technical features assumed for the 2 different plant configurations are underlined: one only with drying chambers and one with an ORC CHP plant configuration coupled to drying chambers. The table reports the assumed efficiencies for thermal oil boiler and for the hot water boiler and also the specific electric own consumptions for each configuration (thermal oil and hot water boiler). It is considered that the product before the drying process in the drying chambers has a moisture percentage of 40% and leaves the drying process with a moisture percentage of 15%. In this study every ORC unit is assumed to supply drying chambers with hot water at a constant feed temperature of 90°C; a drying efficiency of 50% is considered (evaporation energy of the removed water content/thermal energy supplied to drying chamber). The values shown in the table below are derived from our previous experiences and from bibliographic quotations. PLANT TECHNICAL FEATURES Combustion system Thermal oil boiler efficiency (including Split system) Thermal oil boiler own consumption [kWel/MWth] Drying chamber process Inlet wet product moisture Drying efficiency PLANT CONFIGURATION Drying chamber CHP - 90% - 25 Drying chamber CHP 40% 40% 50% 50% Hot water boiler efficiency (including water economizer) 90% - Hot water boiler own consumption [kWel/MWth] 15 - Outlet dry product moisture 15% 15% Hot water temperature inlet drying chamber (about) [°C] 90 90 Table 1 Technical assumptions: Combustion system, Drying chamber process, Power generation system Starting from these assumptions we can obtain a thermal energy requirement of 0.24 MWh/m3 dried wood. Assuming a load factor of 6.500 full load operation hours per year every standard size of the ORC unit can be linked to a yearly dried wood production. In table 2 the technical characteristics of every ORC unit are specified and the production capacity for all ORC sizes is resumed. The table shows: the thermal power input needed by every ORC unit coming from thermal oil; the outlet water temperature from the ORC at 90°C that will be used to feed the drying chambers; the thermal power output to the hot water feeding the drying chambers; THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF TURBODEN SRL. DUPLICATION OR DISCLOSURE TO A THIRD PARTY OF THE INFORMATION CONTAINED HEREIN IS EXPRESSELY FORBIDDEN WITHOUT THE WRITTEN CONSENT OF TURBODEN SRL. - QUESTO DOCUMENTO NON DEVE ESSERE RIPRODOTTO NE` DIVULGATO SENZA AUTORIZZAZIONE SCRITTA DI TURBODEN SRL.PDF Image | APPLICATION OF ORC UNITS IN SAWMILLS. TECHNICAL-ECONOMIC CONSIDERATIONS

PDF Search Title:

APPLICATION OF ORC UNITS IN SAWMILLS. TECHNICAL-ECONOMIC CONSIDERATIONSOriginal File Name Searched:

08A03722_paper_turboden_segherie.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |