PDF Publication Title:

Text from PDF Page: 003

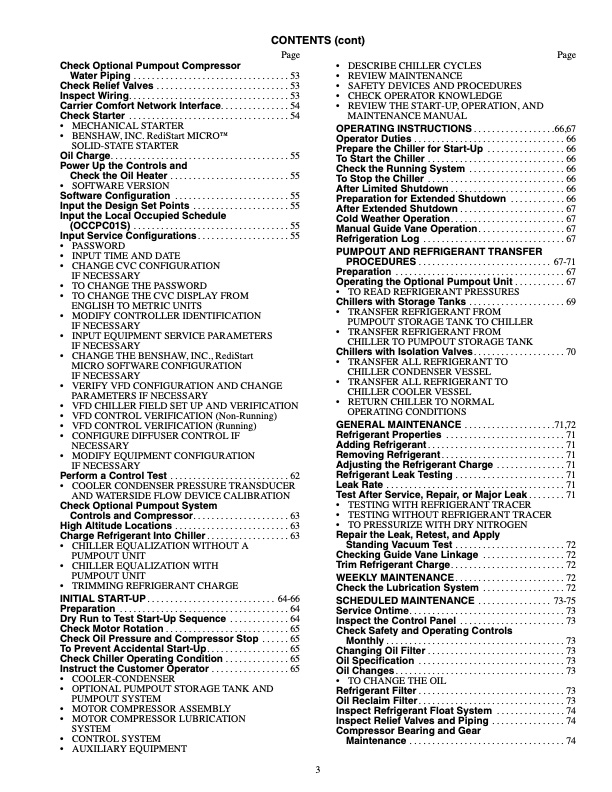

Page Check Optional Pumpout Compressor WaterPiping..................................53 CheckReliefValves.............................53 InspectWiring...................................53 CarrierComfortNetworkInterface...............54 CheckStarter ...................................54 • MECHANICAL STARTER • BENSHAW, INC. RediStart MICROTM SOLID-STATE STARTER Oil Charge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 Power Up the Controls and Check the Oil Heater . . . . . . . . . . . . . . . . . . . . . . . . . . 55 • SOFTWARE VERSION SoftwareConfiguration .........................55 Input the Design Set Points . . . . . . . . . . . . . . . . . . . . . 55 Input the Local Occupied Schedule (OCCPC01S) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 Input Service Configurations. . . . . . . . . . . . . . . . . . . . 55 • PASSWORD • INPUT TIME AND DATE • CHANGE CVC CONFIGURATION IF NECESSARY • TO CHANGE THE PASSWORD • TO CHANGE THE CVC DISPLAY FROM ENGLISH TO METRIC UNITS • MODIFY CONTROLLER IDENTIFICATION IF NECESSARY • INPUT EQUIPMENT SERVICE PARAMETERS IF NECESSARY • CHANGE THE BENSHAW, INC., RediStart MICRO SOFTWARE CONFIGURATION IF NECESSARY • VERIFY VFD CONFIGURATION AND CHANGE PARAMETERS IF NECESSARY • VFD CHILLER FIELD SET UP AND VERIFICATION • VFD CONTROL VERIFICATION (Non-Running) • VFD CONTROL VERIFICATION (Running) • CONFIGURE DIFFUSER CONTROL IF NECESSARY • MODIFY EQUIPMENT CONFIGURATION IF NECESSARY PerformaControlTest..........................62 • COOLER CONDENSER PRESSURE TRANSDUCER AND WATERSIDE FLOW DEVICE CALIBRATION Check Optional Pumpout System ControlsandCompressor.....................63 HighAltitudeLocations.........................63 ChargeRefrigerantIntoChiller..................63 • CHILLER EQUALIZATION WITHOUT A PUMPOUT UNIT • CHILLER EQUALIZATION WITH PUMPOUT UNIT • TRIMMING REFRIGERANT CHARGE INITIALSTART-UP............................ 64-66 Preparation ..................................... 64 Page Dry Run to Test Start-Up Sequence . . . . . . . . . . Check Motor Rotation . . . . . . . . . . . . . . . . . . . . . . . . Check Oil Pressure and Compressor Stop . . . To Prevent Accidental Start-Up. . . . . . . . . . . . . . . Check Chiller Operating Condition . . . . . . . . . . . Instruct the Customer Operator . . . . . . . . . . . . . . • COOLER-CONDENSER • OPTIONAL PUMPOUT STORAGE TANK AND PUMPOUT SYSTEM • MOTOR COMPRESSOR ASSEMBLY • MOTOR COMPRESSOR LUBRICATION SYSTEM • CONTROL SYSTEM • AUXILIARY EQUIPMENT . . . 64 . . . 65 . . . 65 . . . 65 . . . 65 . . . 65 • DESCRIBE CHILLER CYCLES • REVIEW MAINTENANCE • SAFETY DEVICES AND PROCEDURES • CHECK OPERATOR KNOWLEDGE • REVIEW THE START-UP, OPERATION, AND MAINTENANCE MANUAL OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . .66,67 Operator Duties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 PreparetheChillerforStart-Up .................66 To Start the Chiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 ChecktheRunningSystem ..................... 66 ToStoptheChiller .............................. 66 AfterLimitedShutdown......................... 66 PreparationforExtendedShutdown ............66 AfterExtendedShutdown....................... 67 Cold Weather Operation. . . . . . . . . . . . . . . . . . . . . . . . . 67 Manual Guide Vane Operation. . . . . . . . . . . . . . . . . . . 67 RefrigerationLog ...............................67 PUMPOUT AND REFRIGERANT TRANSFER PROCEDURES............................. 67-71 Preparation ..................................... 67 OperatingtheOptionalPumpoutUnit........... 67 • TO READ REFRIGERANT PRESSURES Chillers with Storage Tanks . . . . . . . . . . . . . . . . . . . . . 69 • TRANSFER REFRIGERANT FROM PUMPOUT STORAGE TANK TO CHILLER • TRANSFER REFRIGERANT FROM CHILLER TO PUMPOUT STORAGE TANK Chillers with Isolation Valves. . . . . . . . . . . . . . . . . . . . 70 • TRANSFER ALL REFRIGERANT TO CHILLER CONDENSER VESSEL • TRANSFER ALL REFRIGERANT TO CHILLER COOLER VESSEL • RETURN CHILLER TO NORMAL OPERATING CONDITIONS GENERALMAINTENANCE....................71,72 RefrigerantProperties .......................... 71 AddingRefrigerant.............................. 71 RemovingRefrigerant........................... 71 AdjustingtheRefrigerantCharge...............71 RefrigerantLeakTesting........................ 71 LeakRate.......................................71 Test After Service, Repair, or Major Leak. . . . . . . . 71 • TESTING WITH REFRIGERANT TRACER • TESTING WITHOUT REFRIGERANT TRACER • TO PRESSURIZE WITH DRY NITROGEN Repair the Leak, Retest, and Apply Standing Vacuum Test . . . . . . . . . . . . . . . . . . . . . . . . 72 CheckingGuideVaneLinkage ..................72 TrimRefrigerantCharge......................... 72 WEEKLYMAINTENANCE........................ 72 ChecktheLubricationSystem .................. 72 SCHEDULEDMAINTENANCE ................ 73-75 ServiceOntime.................................. 73 Inspect the Control Panel . . . . . . . . . . . . . . . . . . . . . . . 73 Check Safety and Operating Controls Monthly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73 ChangingOilFilter.............................. 73 OilSpecification ................................ 73 Oil Changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73 • TO CHANGE THE OIL RefrigerantFilter................................ 73 OilReclaimFilter................................ 73 InspectRefrigerantFloatSystem ...............74 Inspect Relief Valves and Piping . . . . . . . . . . . . . . . . 74 Compressor Bearing and Gear Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74 CONTENTS (cont) 3PDF Image | 19XR,XRV Hermetic Centrifugal Liquid Chillers 50/60 Hz With PIC II Controls and HFC-134a

PDF Search Title:

19XR,XRV Hermetic Centrifugal Liquid Chillers 50/60 Hz With PIC II Controls and HFC-134aOriginal File Name Searched:

19xr_4ss_Startup_PICII.pdfDIY PDF Search: Google It | Yahoo | Bing

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

IT XR Project Redstone NFT Available for Sale: NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Be part of the future with this NFT. Can be bought and sold but only one design NFT exists. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Turbine IT XR Project Redstone Design: NFT for sale... NFT for high tech turbine design with one part 3D printed counter-rotating energy turbine. Includes all rights to this turbine design, including license for Fluid Handling Block I and II for the turbine assembly and housing. The NFT includes the blueprints (cad/cam), revenue streams, and all future development of the IT XR Project Redstone... More Info

Infinity Turbine ROT Radial Outflow Turbine 24 Design and Worldwide Rights: NFT for sale... NFT for the ROT 24 energy turbine. Be part of the future with this NFT. This design can be bought and sold but only one design NFT exists. You may manufacture the unit, or get the revenues from its sale from Infinity Turbine. Royalties go to the developer (Infinity) to keep enhancing design and applications... More Info

Infinity Supercritical CO2 10 Liter Extractor Design and Worldwide Rights: The Infinity Supercritical 10L CO2 extractor is for botanical oil extraction, which is rich in terpenes and can produce shelf ready full spectrum oil. With over 5 years of development, this industry leader mature extractor machine has been sold since 2015 and is part of many profitable businesses. The process can also be used for electrowinning, e-waste recycling, and lithium battery recycling, gold mining electronic wastes, precious metals. CO2 can also be used in a reverse fuel cell with nafion to make a gas-to-liquids fuel, such as methanol, ethanol and butanol or ethylene. Supercritical CO2 has also been used for treating nafion to make it more effective catalyst. This NFT is for the purchase of worldwide rights which includes the design. More Info

NFT (Non Fungible Token): Buy our tech, design, development or system NFT and become part of our tech NFT network... More Info

Infinity Turbine Products: Special for this month, any plans are $10,000 for complete Cad/Cam blueprints. License is for one build. Try before you buy a production license. May pay by Bitcoin or other Crypto. Products Page... More Info

| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |