PDF Publication Title:

Text from PDF Page: 002

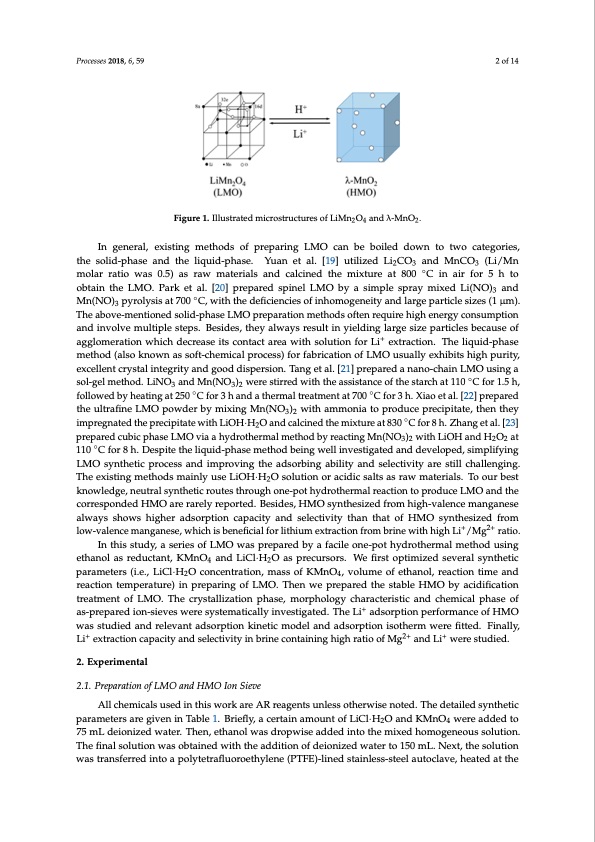

Processes 2018, 6, 59 2 of 14 Processes 2018, 6, x FOR PEER REVIEW 2 of 14 Figure 1. Illustrated microstructures of LiMn2O4 and λ-MnO2. Figure 1. Illustrated microstructures of LiMn2O4 and λ-MnO2. In general, existing methods of preparing LMO can be boiled down to two categories, the solid-phase and the liquid-phase. Yuan et al. [19] utilized Li2CO3 and MnCO3 (Li/Mn molar ratio was In general, existing methods of preparing LMO can be boiled down to two categories, 0.5) as raw materials and calcined the mixture at 800 °C in air for 5 h to obtain the LMO. Park et al. the solid-phase and the liquid-phase. Yuan et al. [19] utilized Li CO and MnCO (Li/Mn [20] prepared spinel LMO by a simple spray mixed Li(NO)3 and Mn(NO)3 p2yroly3sis at 700 C, with3 ◦ molar ratitohe wdeafiscie0n.c5ie)s oafsinrhaowmogmenaetietyriaanlds larngedpacratilccleinsiezdes (t1hμemm). Tixhteuarbeovae-tm8en0t0ioneCd soinlid-apihrasfeor 5 h to LMO preparation methods often require high energy consumption and involve multiple steps. obtain the LMO. Park et al. [20] prepared spinel LMO by a simple spray mixed Li(NO)3 and Besides, they always result in yielding large size particles because of agglomeration which decrease Mn(NO) pyrolysisat700◦C,withthedeficienciesofinhomogeneityandlargeparticlesizes(1μm). 3 its contact area with solution for Li+ extraction. The liquid-phase method (also known as The above-mentioned solid-phase LMO preparation methods often require high energy consumption soft-chemical process) for fabrication of LMO usually exhibits high purity, excellent crystal integrity and involvanedmgouoldtidpislepesrstieopns. T. aBngeseitdale.s[2,1t]hpereyparlewdaynsanroe-schualitniLnMyOieulsdinignagsloal-rggeel mseiztheodp.aLriNtiOcl3easndbecause of Mn(NO3)2 were stirred with the assistance of the starch at 110 °C for 1.5 h,+followed by heating at 250 agglomeration which decrease its contact area with solution for Li extraction. The liquid-phase °C for 3 h and a thermal treatment at 700 °C for 3 h. Xiao et al. [22] prepared the ultrafine LMO method (also known as soft-chemical process) for fabrication of LMO usually exhibits high purity, powder by mixing Mn(NO3)2 with ammonia to produce precipitate, then they impregnated the excellent crystal integrity and good dispersion. Tang et al. [21] prepared a nano-chain LMO using a precipitate with LiOH·H2O and calcined the mixture at 830 °C for 8 h. Zhang et al. [23] prepared 3)t for 8 h. Despite the ◦liquid-phase method being well investigated and◦developed, simplifying LMO followed by heating at 250 C for 3 h and a thermal treatment at 700 C for 3 h. Xiao et al. [22] prepared sol-gel metchuobidc.pLhaiNseOLMOanvdiaMa hny(dNroOthe)rmwalemretshtoirdrbeydrweaicthingthMena(NssOis 332 hO2 aatt110°CC for 1.5 h, synthetic process and improving the adsorbing ability and selectivity are still challenging. The the ultrafine LMO powder by mixing Mn(NO3)2 with ammonia to produce precipitate, then they existing methods mainly use LiOH·H2O solution or acidic salts as raw materials. To our best impregnated the precipitate with LiOH·H O and calcined the mixture at 830 ◦C for 8 h. Zhang et al. [23] knowledge, neutral synthetic routes t2hrough one-pot hydrothermal reaction to produce LMO and prepared ctuhbeicoprhreasspeonLdMedOHvMiaOa ahryedraortehlyerrmepaolrtmede.thBoesdidbeys, rHeaMcOtinsgynMthne(sNizeOd )frowmithigLhi-OvaHlenacned H O at 32 22 ◦ manganese always shows higher adsorption capacity and selectivity than that of HMO synthesized C for 8 h. Despite the liquid-phase method being well investigated and developed, simplifying 110 LMO synthetic process and improving the adsorbing ability and selectivity are still challenging. from low-valence manganese, which is beneficial for lithium extraction from brine with high Li+/Mg2+ ratio. The existing methods mainly use LiOH·H O solution or acidic salts as raw materials. To our best In this study, a series of LMO was 2prepared by a facile one-pot hydrothermal method using knowledge,thnaenuoltraasl rseydnucthtaenti,cKrMounOte4satnhdroLuiCglh·Ho2Onea-spportechuyrsdoros.thWeermfiraslt roepaticmtiiozendtosepverroadl usycnethLeMticO and the parameters (i.e., LiCl·H2O concentration, mass of KMnO4, volume of ethanol, reaction time and corresponded HMO are rarely reported. Besides, HMO synthesized from high-valence manganese reaction temperature) in preparing of LMO. Then we prepared the stable HMO by acidification always shows higher adsorption capacity and selectivity than that of HMO synthesized from treatment of LMO. The crystallization phase, morphology characteristic and chemical phase of low-valence manganese, which is beneficial for lithium extractio as-prepared ion-sieves were systematically investigated. The Li adsorption performance of HMO + In thiwsastsutuddyi,edaasnedrirelsevoafntLaMdsoOrpwtioanskpinreetipcamroedelbayndaadfasocripletioonniseo-tphoertmhwyedrreofitthteedr.mFinaalllmy,eLtihod using extraction capacity and selectivity in brine containing high ratio of Mg2+ and Li+ were studied. ethanol as reductant, KMnO4 and LiCl·H2O as precursors. We first optimized several synthetic parameters (i.e., LiCl·H2O concentration, mass of KMnO4, volume of ethanol, reaction time and 2. Experimental reaction temperature) in preparing of LMO. Then we prepared the stable HMO by acidification 2.1. Preparation of LMO and HMO Ion Sieve treatment of LMO. The crystallization phase, morphology characteristic and chemical phase of as-prepared ion-sieves were systematically investigated. The Li+ adsorption performance of HMO All chemicals used in this work are AR reagents unless otherwise noted. The detailed synthetic parameters are given in Table 1. Briefly, a certain amount of LiCl·H2O and KMnO4 were added to 75 was studied and relevant adsorption kinetic model and adsorption isotherm were fitted. Finally, mL deionized water. Then, ethanol was dropwise added into the mixed homogeneous solution. The Li+ extraction capacity and selectivity in brine containing high ratio of Mg2+ and Li+ were studied. final solution was obtained with the addition of deionized water to 150 mL. Next, the solution was transferred into a polytetrafluoroethylene (PTFE)-lined stainless-steel autoclave, heated at the 2. Experimental 2.1. Preparation of LMO and HMO Ion Sieve All chemicals used in this work are AR reagents unless otherwise noted. The detailed synthetic parameters are given in Table 1. Briefly, a certain amount of LiCl·H2O and KMnO4 were added to 75 mL deionized water. Then, ethanol was dropwise added into the mixed homogeneous solution. The final solution was obtained with the addition of deionized water to 150 mL. Next, the solution was transferred into a polytetrafluoroethylene (PTFE)-lined stainless-steel autoclave, heated at the + 2 awnciteh oLifOtHheanstdaHrc ◦ 2 + 2+ n from brine with high Li /Mg ratio.PDF Image | Sieves for Highly Selective Li Adsorption

PDF Search Title:

Sieves for Highly Selective Li AdsorptionOriginal File Name Searched:

processes-06-00059-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |