PDF Publication Title:

Text from PDF Page: 205

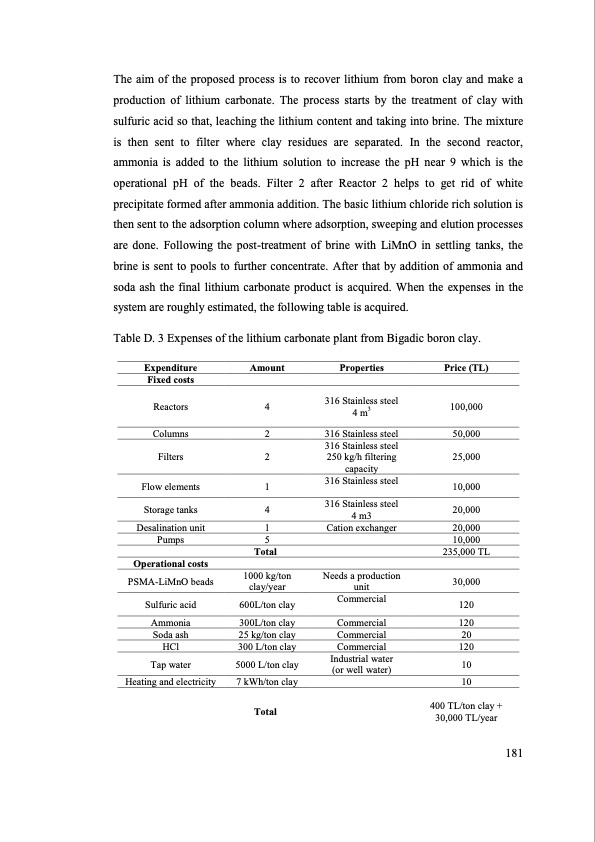

The aim of the proposed process is to recover lithium from boron clay and make a production of lithium carbonate. The process starts by the treatment of clay with sulfuric acid so that, leaching the lithium content and taking into brine. The mixture is then sent to filter where clay residues are separated. In the second reactor, ammonia is added to the lithium solution to increase the pH near 9 which is the operational pH of the beads. Filter 2 after Reactor 2 helps to get rid of white precipitate formed after ammonia addition. The basic lithium chloride rich solution is then sent to the adsorption column where adsorption, sweeping and elution processes are done. Following the post-treatment of brine with LiMnO in settling tanks, the brine is sent to pools to further concentrate. After that by addition of ammonia and soda ash the final lithium carbonate product is acquired. When the expenses in the system are roughly estimated, the following table is acquired. Table D. 3 Expenses of the lithium carbonate plant from Bigadic boron clay. Expenditure Fixed costs Reactors Columns Filters Flow elements Storage tanks Desalination unit Pumps Operational costs PSMA-LiMnO beads Sulfuric acid Ammonia Soda ash HCl Tap water Heating and electricity Amount 4 2 2 1 4 1 5 Total 1000 kg/ton clay/year 600L/ton clay 300L/ton clay 25 kg/ton clay 300 L/ton clay 5000 L/ton clay 7 kWh/ton clay Total Properties 316 Stainless steel 4 m3 316 Stainless steel 316 Stainless steel 250 kg/h filtering capacity 316 Stainless steel 316 Stainless steel 4 m3 Cation exchanger Needs a production unit Commercial Commercial Commercial Commercial Industrial water (or well water) Price (TL) 100,000 50,000 25,000 10,000 20,000 20,000 10,000 235,000 TL 30,000 120 120 20 120 10 10 400 TL/ton clay + 30,000 TL/year 181PDF Image | SEPARATION OF LITHIUM FROM BRINES

PDF Search Title:

SEPARATION OF LITHIUM FROM BRINESOriginal File Name Searched:

separation-lithium-from-brine.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |