PDF Publication Title:

Text from PDF Page: 146

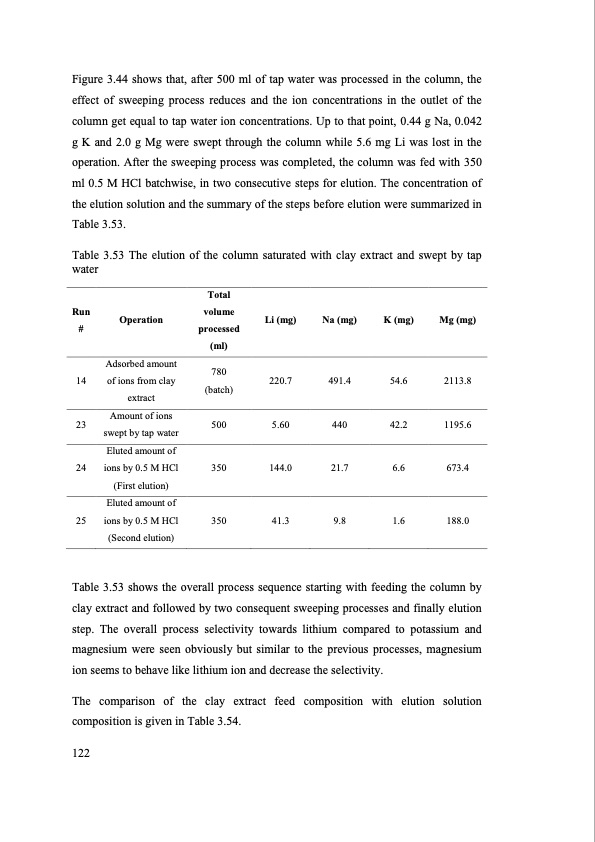

Figure 3.44 shows that, after 500 ml of tap water was processed in the column, the effect of sweeping process reduces and the ion concentrations in the outlet of the column get equal to tap water ion concentrations. Up to that point, 0.44 g Na, 0.042 g K and 2.0 g Mg were swept through the column while 5.6 mg Li was lost in the operation. After the sweeping process was completed, the column was fed with 350 ml 0.5 M HCl batchwise, in two consecutive steps for elution. The concentration of the elution solution and the summary of the steps before elution were summarized in Table 3.53. Table 3.53 The elution of the column saturated with clay extract and swept by tap water Run # 14 23 24 25 Operation Total volume Li (mg) processed (ml) Na (mg) 491.4 440 21.7 9.8 K (mg) 54.6 42.2 6.6 1.6 Mg (mg) 2113.8 1195.6 673.4 188.0 Adsorbed amount 780 of ions from clay extract Amount of ions swept by tap water Eluted amount of ions by 0.5 M HCl (First elution) Eluted amount of ions by 0.5 M HCl (Second elution) (batch) 220.7 500 5.60 350 144.0 350 41.3 Table 3.53 shows the overall process sequence starting with feeding the column by clay extract and followed by two consequent sweeping processes and finally elution step. The overall process selectivity towards lithium compared to potassium and magnesium were seen obviously but similar to the previous processes, magnesium ion seems to behave like lithium ion and decrease the selectivity. The comparison of the clay extract feed composition with elution solution composition is given in Table 3.54. 122PDF Image | SEPARATION OF LITHIUM FROM BRINES

PDF Search Title:

SEPARATION OF LITHIUM FROM BRINESOriginal File Name Searched:

separation-lithium-from-brine.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |