PDF Publication Title:

Text from PDF Page: 141

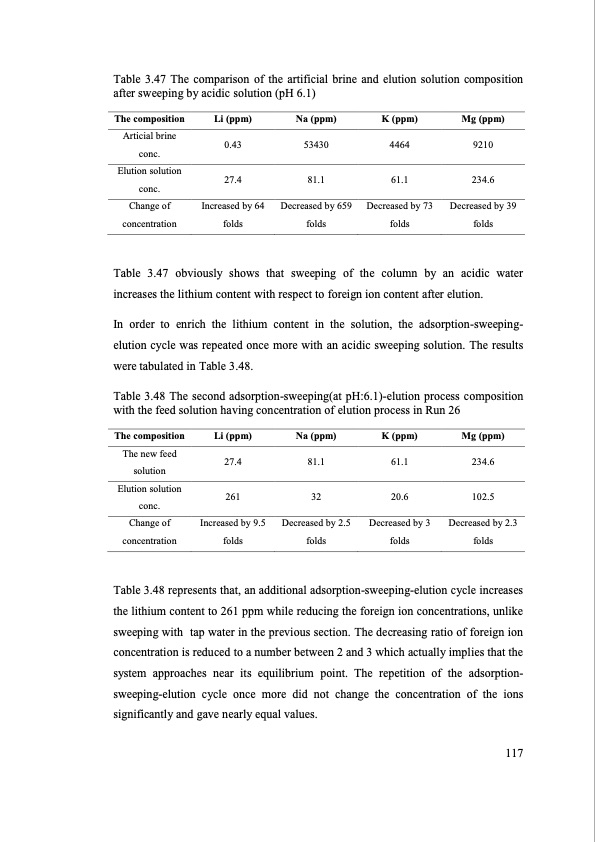

Table 3.47 The comparison of the artificial brine and elution solution composition after sweeping by acidic solution (pH 6.1) The composition Articial brine conc. Elution solution conc. Change of concentration Li (ppm) 0.43 27.4 Increased by 64 folds Na (ppm) 53430 81.1 Decreased by 659 folds K (ppm) 4464 61.1 Decreased by 73 folds Mg (ppm) 9210 234.6 Decreased by 39 folds Table 3.47 obviously shows that sweeping of the column by an acidic water increases the lithium content with respect to foreign ion content after elution. In order to enrich the lithium content in the solution, the adsorption-sweeping- elution cycle was repeated once more with an acidic sweeping solution. The results were tabulated in Table 3.48. Table 3.48 The second adsorption-sweeping(at pH:6.1)-elution process composition with the feed solution having concentration of elution process in Run 26 The composition The new feed solution Elution solution conc. Change of concentration Li (ppm) 27.4 261 Increased by 9.5 folds Na (ppm) 81.1 32 Decreased by 2.5 folds K (ppm) 61.1 20.6 Decreased by 3 folds Mg (ppm) 234.6 102.5 Decreased by 2.3 folds Table 3.48 represents that, an additional adsorption-sweeping-elution cycle increases the lithium content to 261 ppm while reducing the foreign ion concentrations, unlike sweeping with tap water in the previous section. The decreasing ratio of foreign ion concentration is reduced to a number between 2 and 3 which actually implies that the system approaches near its equilibrium point. The repetition of the adsorption- sweeping-elution cycle once more did not change the concentration of the ions significantly and gave nearly equal values. 117PDF Image | SEPARATION OF LITHIUM FROM BRINES

PDF Search Title:

SEPARATION OF LITHIUM FROM BRINESOriginal File Name Searched:

separation-lithium-from-brine.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |