PDF Publication Title:

Text from PDF Page: 126

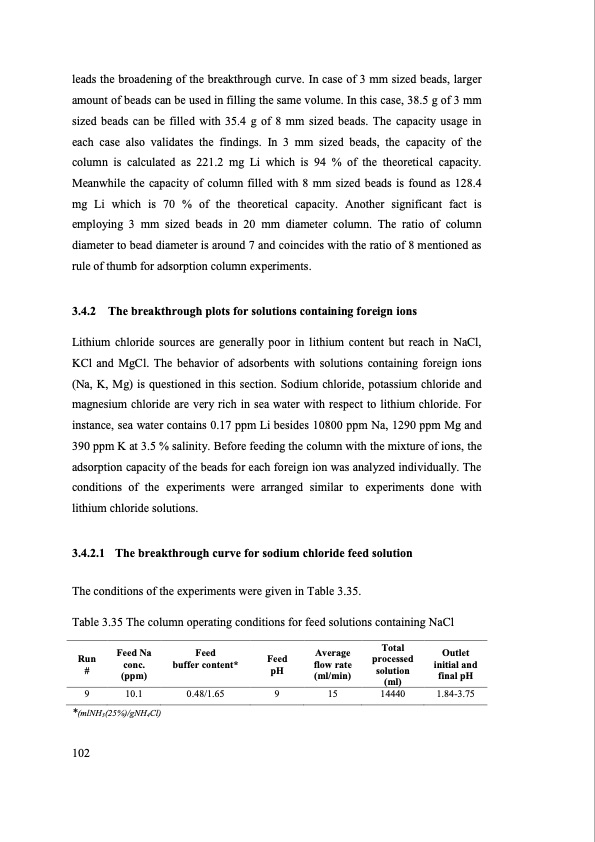

leads the broadening of the breakthrough curve. In case of 3 mm sized beads, larger amount of beads can be used in filling the same volume. In this case, 38.5 g of 3 mm sized beads can be filled with 35.4 g of 8 mm sized beads. The capacity usage in each case also validates the findings. In 3 mm sized beads, the capacity of the column is calculated as 221.2 mg Li which is 94 % of the theoretical capacity. Meanwhile the capacity of column filled with 8 mm sized beads is found as 128.4 mg Li which is 70 % of the theoretical capacity. Another significant fact is employing 3 mm sized beads in 20 mm diameter column. The ratio of column diameter to bead diameter is around 7 and coincides with the ratio of 8 mentioned as rule of thumb for adsorption column experiments. 3.4.2 The breakthrough plots for solutions containing foreign ions Lithium chloride sources are generally poor in lithium content but reach in NaCl, KCl and MgCl. The behavior of adsorbents with solutions containing foreign ions (Na, K, Mg) is questioned in this section. Sodium chloride, potassium chloride and magnesium chloride are very rich in sea water with respect to lithium chloride. For instance, sea water contains 0.17 ppm Li besides 10800 ppm Na, 1290 ppm Mg and 390 ppm K at 3.5 % salinity. Before feeding the column with the mixture of ions, the adsorption capacity of the beads for each foreign ion was analyzed individually. The conditions of the experiments were arranged similar to experiments done with lithium chloride solutions. 3.4.2.1 The breakthrough curve for sodium chloride feed solution The conditions of the experiments were given in Table 3.35. Table 3.35 The column operating conditions for feed solutions containing NaCl Run # 9 Feed Na conc. (ppm) 10.1 Feed buffer content* 0.48/1.65 Average Feed flow rate pH (ml/min) 9 15 Total processed solution (ml) 14440 Outlet initial and final pH 1.84-3.75 *(mlNH3(25%)/gNH4Cl) 102PDF Image | SEPARATION OF LITHIUM FROM BRINES

PDF Search Title:

SEPARATION OF LITHIUM FROM BRINESOriginal File Name Searched:

separation-lithium-from-brine.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |