PDF Publication Title:

Text from PDF Page: 016

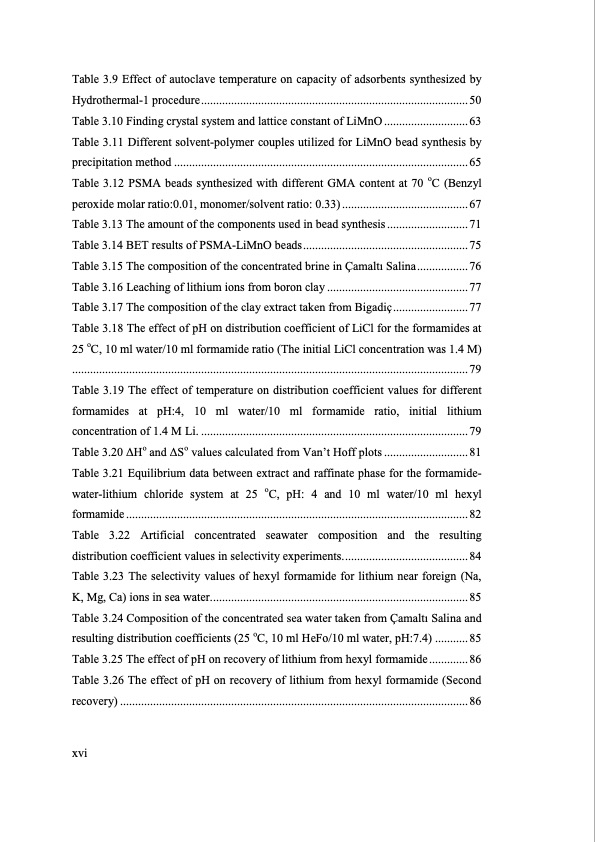

Table 3.9 Effect of autoclave temperature on capacity of adsorbents synthesized by Hydrothermal-1 procedure.........................................................................................50 Table 3.10 Finding crystal system and lattice constant of LiMnO ............................ 63 Table 3.11 Different solvent-polymer couples utilized for LiMnO bead synthesis by precipitation method .................................................................................................. 65 Table 3.12 PSMA beads synthesized with different GMA content at 70 oC (Benzyl peroxide molar ratio:0.01, monomer/solvent ratio: 0.33) .......................................... 67 Table 3.13 The amount of the components used in bead synthesis ........................... 71 Table 3.14 BET results of PSMA-LiMnO beads.......................................................75 Table 3.15 The composition of the concentrated brine in Çamaltı Salina.................76 Table 3.16 Leaching of lithium ions from boron clay ............................................... 77 Table 3.17 The composition of the clay extract taken from Bigadiç.........................77 Table 3.18 The effect of pH on distribution coefficient of LiCl for the formamides at 25 oC, 10 ml water/10 ml formamide ratio (The initial LiCl concentration was 1.4 M) .................................................................................................................................... 79 Table 3.19 The effect of temperature on distribution coefficient values for different formamides at pH:4, 10 ml water/10 ml formamide ratio, initial lithium concentration of 1.4 M Li. ......................................................................................... 79 Table 3.20 ΔHo and ΔSo values calculated from Van’t Hoff plots ............................ 81 Table 3.21 Equilibrium data between extract and raffinate phase for the formamide- water-lithium chloride system at 25 oC, pH: 4 and 10 ml water/10 ml hexyl formamide .................................................................................................................. 82 Table 3.22 Artificial concentrated seawater composition and the resulting distribution coefficient values in selectivity experiments.......................................... 84 Table 3.23 The selectivity values of hexyl formamide for lithium near foreign (Na, K, Mg, Ca) ions in sea water...................................................................................... 85 Table 3.24 Composition of the concentrated sea water taken from Çamaltı Salina and resulting distribution coefficients (25 oC, 10 ml HeFo/10 ml water, pH:7.4) ........... 85 Table 3.25 The effect of pH on recovery of lithium from hexyl formamide.............86 Table 3.26 The effect of pH on recovery of lithium from hexyl formamide (Second recovery) .................................................................................................................... 86 xviPDF Image | SEPARATION OF LITHIUM FROM BRINES

PDF Search Title:

SEPARATION OF LITHIUM FROM BRINESOriginal File Name Searched:

separation-lithium-from-brine.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |