PDF Publication Title:

Text from PDF Page: 024

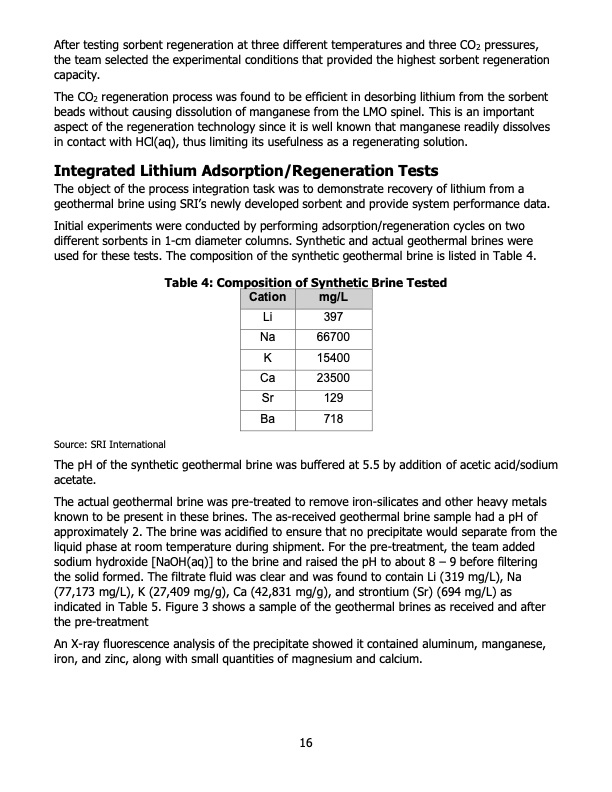

After testing sorbent regeneration at three different temperatures and three CO2 pressures, the team selected the experimental conditions that provided the highest sorbent regeneration capacity. The CO2 regeneration process was found to be efficient in desorbing lithium from the sorbent beads without causing dissolution of manganese from the LMO spinel. This is an important aspect of the regeneration technology since it is well known that manganese readily dissolves in contact with HCl(aq), thus limiting its usefulness as a regenerating solution. Integrated Lithium Adsorption/Regeneration Tests The object of the process integration task was to demonstrate recovery of lithium from a geothermal brine using SRI’s newly developed sorbent and provide system performance data. Initial experiments were conducted by performing adsorption/regeneration cycles on two different sorbents in 1-cm diameter columns. Synthetic and actual geothermal brines were used for these tests. The composition of the synthetic geothermal brine is listed in Table 4. Table 4: Composition of Synthetic Brine Tested Cation mg/L Li 397 Na K Ca 66700 15400 23500 Sr 129 Ba 718 Source: SRI International The pH of the synthetic geothermal brine was buffered at 5.5 by addition of acetic acid/sodium acetate. The actual geothermal brine was pre-treated to remove iron-silicates and other heavy metals known to be present in these brines. The as-received geothermal brine sample had a pH of approximately 2. The brine was acidified to ensure that no precipitate would separate from the liquid phase at room temperature during shipment. For the pre-treatment, the team added sodium hydroxide [NaOH(aq)] to the brine and raised the pH to about 8 – 9 before filtering the solid formed. The filtrate fluid was clear and was found to contain Li (319 mg/L), Na (77,173 mg/L), K (27,409 mg/g), Ca (42,831 mg/g), and strontium (Sr) (694 mg/L) as indicated in Table 5. Figure 3 shows a sample of the geothermal brines as received and after the pre-treatment An X-ray fluorescence analysis of the precipitate showed it contained aluminum, manganese, iron, and zinc, along with small quantities of magnesium and calcium. 16PDF Image | Selective Recovery of Lithium from Geothermal Brines

PDF Search Title:

Selective Recovery of Lithium from Geothermal BrinesOriginal File Name Searched:

CEC-500-2020-020.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |