PDF Publication Title:

Text from PDF Page: 002

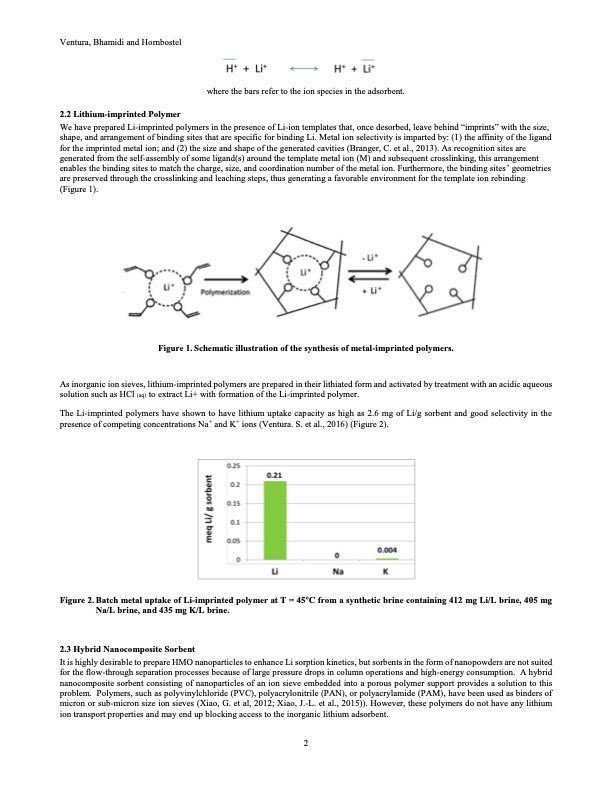

Ventura, Bhamidi and Hornbostel 2.2 Lithium-imprinted Polymer where the bars refer to the ion species in the adsorbent. We have prepared Li-imprinted polymers in the presence of Li-ion templates that, once desorbed, leave behind “imprints” with the size, shape, and arrangement of binding sites that are specific for binding Li. Metal ion selectivity is imparted by: (1) the affinity of the ligand for the imprinted metal ion; and (2) the size and shape of the generated cavities (Branger, C. et al., 2013). As recognition sites are generated from the self-assembly of some ligand(s) around the template metal ion (M) and subsequent crosslinking, this arrangement enables the binding sites to match the charge, size, and coordination number of the metal ion. Furthermore, the binding sites’ geometries are preserved through the crosslinking and leaching steps, thus generating a favorable environment for the template ion rebinding (Figure 1). Figure 1. Schematic illustration of the synthesis of metal-imprinted polymers. As inorganic ion sieves, lithium-imprinted polymers are prepared in their lithiated form and activated by treatment with an acidic aqueous solution such as HCl (aq) to extract Li+ with formation of the Li-imprinted polymer. The Li-imprinted polymers have shown to have lithium uptake capacity as high as 2.6 mg of Li/g sorbent and good selectivity in the presence of competing concentrations Na+ and K+ ions (Ventura. S. et al., 2016) (Figure 2). Figure 2. Batch metal uptake of Li-imprinted polymer at T = 45oC from a synthetic brine containing 412 mg Li/L brine, 405 mg Na/L brine, and 435 mg K/L brine. 2.3 Hybrid Nanocomposite Sorbent It is highly desirable to prepare HMO nanoparticles to enhance Li sorption kinetics, but sorbents in the form of nanopowders are not suited for the flow-through separation processes because of large pressure drops in column operations and high-energy consumption. A hybrid nanocomposite sorbent consisting of nanoparticles of an ion sieve embedded into a porous polymer support provides a solution to this problem. Polymers, such as polyvinylchloride (PVC), polyacrylonitrile (PAN), or polyacrylamide (PAM), have been used as binders of micron or sub-micron size ion sieves (Xiao, G. et al, 2012; Xiao, J.-L. et al., 2015)). However, these polymers do not have any lithium ion transport properties and may end up blocking access to the inorganic lithium adsorbent. 2PDF Image | Selective Recovery of Lithium from Brines

PDF Search Title:

Selective Recovery of Lithium from BrinesOriginal File Name Searched:

Ventura.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |