PDF Publication Title:

Text from PDF Page: 046

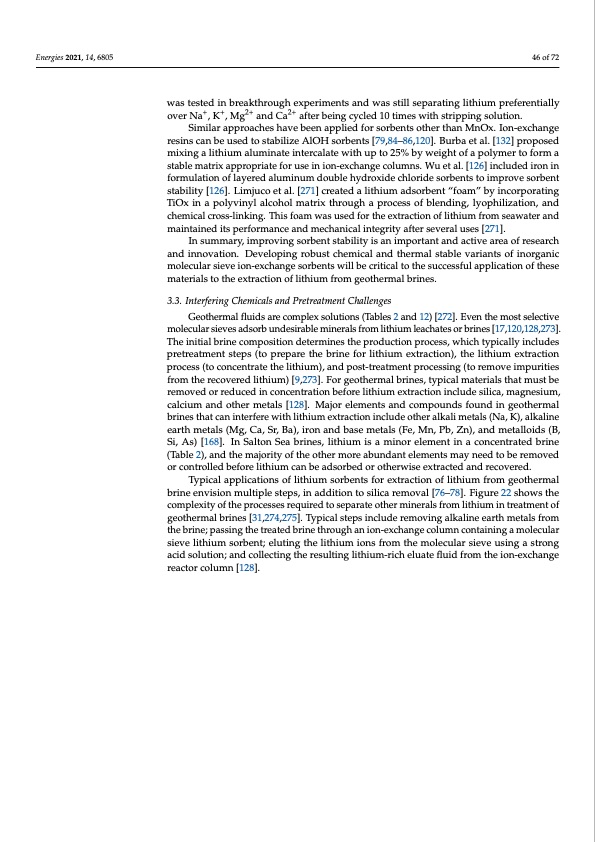

Energies 2021, 14, 6805 46 of 72 was tested in breakthrough experiments and was still separating lithium preferentially over Na+, K+, Mg2+ and Ca2+ after being cycled 10 times with stripping solution. Similar approaches have been applied for sorbents other than MnOx. Ion-exchange resins can be used to stabilize AlOH sorbents [79,84–86,120]. Burba et al. [132] proposed mixing a lithium aluminate intercalate with up to 25% by weight of a polymer to form a stable matrix appropriate for use in ion-exchange columns. Wu et al. [126] included iron in formulation of layered aluminum double hydroxide chloride sorbents to improve sorbent stability [126]. Limjuco et al. [271] created a lithium adsorbent “foam” by incorporating TiOx in a polyvinyl alcohol matrix through a process of blending, lyophilization, and chemical cross-linking. This foam was used for the extraction of lithium from seawater and maintained its performance and mechanical integrity after several uses [271]. In summary, improving sorbent stability is an important and active area of research and innovation. Developing robust chemical and thermal stable variants of inorganic molecular sieve ion-exchange sorbents will be critical to the successful application of these materials to the extraction of lithium from geothermal brines. 3.3. Interfering Chemicals and Pretreatment Challenges Geothermal fluids are complex solutions (Tables 2 and 12) [272]. Even the most selective molecular sieves adsorb undesirable minerals from lithium leachates or brines [17,120,128,273]. The initial brine composition determines the production process, which typically includes pretreatment steps (to prepare the brine for lithium extraction), the lithium extraction process (to concentrate the lithium), and post-treatment processing (to remove impurities from the recovered lithium) [9,273]. For geothermal brines, typical materials that must be removed or reduced in concentration before lithium extraction include silica, magnesium, calcium and other metals [128]. Major elements and compounds found in geothermal brines that can interfere with lithium extraction include other alkali metals (Na, K), alkaline earth metals (Mg, Ca, Sr, Ba), iron and base metals (Fe, Mn, Pb, Zn), and metalloids (B, Si, As) [168]. In Salton Sea brines, lithium is a minor element in a concentrated brine (Table 2), and the majority of the other more abundant elements may need to be removed or controlled before lithium can be adsorbed or otherwise extracted and recovered. Typical applications of lithium sorbents for extraction of lithium from geothermal brine envision multiple steps, in addition to silica removal [76–78]. Figure 22 shows the complexity of the processes required to separate other minerals from lithium in treatment of geothermal brines [31,274,275]. Typical steps include removing alkaline earth metals from the brine; passing the treated brine through an ion-exchange column containing a molecular sieve lithium sorbent; eluting the lithium ions from the molecular sieve using a strong acid solution; and collecting the resulting lithium-rich eluate fluid from the ion-exchange reactor column [128].PDF Image | Recovery of Lithium from Geothermal Brines

PDF Search Title:

Recovery of Lithium from Geothermal BrinesOriginal File Name Searched:

energies-14-06805-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |