PDF Publication Title:

Text from PDF Page: 002

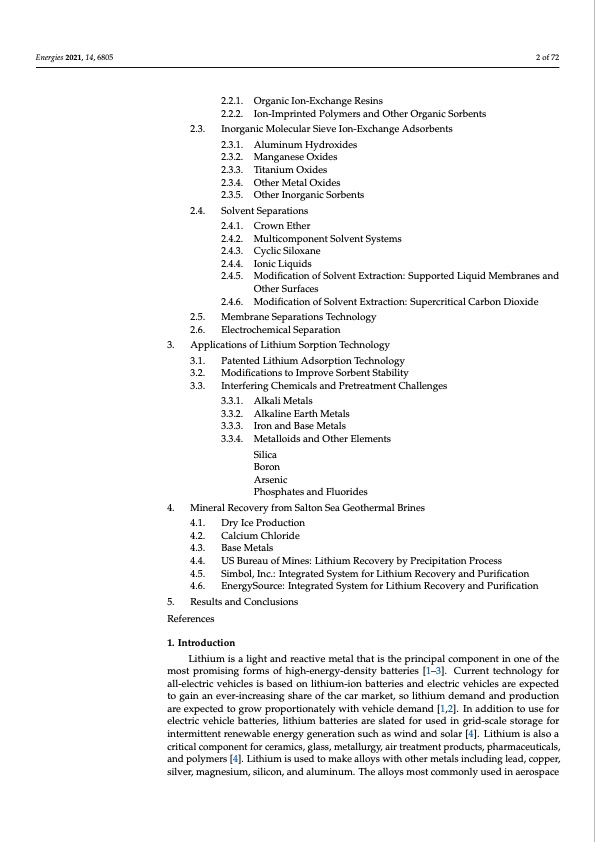

Energies 2021, 14, 6805 2 of 72 2.2.1. 2.2.2. Organic Ion-Exchange Resins Ion-Imprinted Polymers and Other Organic Sorbents 2.3. Inorganic Molecular Sieve Ion-Exchange Adsorbents 2.3.1. Aluminum Hydroxides 2.3.2. Manganese Oxides 2.3.3. Titanium Oxides 2.3.4. Other Metal Oxides 2.3.5. Other Inorganic Sorbents 2.4. Solvent Separations 2.4.1. Crown Ether 2.4.2. Multicomponent Solvent Systems 2.4.3. Cyclic Siloxane 2.4.4. Ionic Liquids 2.4.5. Modification of Solvent Extraction: Supported Liquid Membranes and Other Surfaces 2.4.6. Modification of Solvent Extraction: Supercritical Carbon Dioxide 2.5. Membrane Separations Technology 2.6. Electrochemical Separation 3. Applications of Lithium Sorption Technology 3.1. Patented Lithium Adsorption Technology 3.2. Modifications to Improve Sorbent Stability 3.3. Interfering Chemicals and Pretreatment Challenges 3.3.1. Alkali Metals 3.3.2. Alkaline Earth Metals 3.3.3. Iron and Base Metals 3.3.4. Metalloids and Other Elements Silica Boron Arsenic Phosphates and Fluorides 4. Mineral Recovery from Salton Sea Geothermal Brines 4.1. Dry Ice Production 4.2. Calcium Chloride 4.3. Base Metals 4.4. US Bureau of Mines: Lithium Recovery by Precipitation Process 4.5. Simbol, Inc.: Integrated System for Lithium Recovery and Purification 4.6. EnergySource: Integrated System for Lithium Recovery and Purification 5. Results and Conclusions References 1. Introduction Lithium is a light and reactive metal that is the principal component in one of the most promising forms of high-energy-density batteries [1–3]. Current technology for all-electric vehicles is based on lithium-ion batteries and electric vehicles are expected to gain an ever-increasing share of the car market, so lithium demand and production are expected to grow proportionately with vehicle demand [1,2]. In addition to use for electric vehicle batteries, lithium batteries are slated for used in grid-scale storage for intermittent renewable energy generation such as wind and solar [4]. Lithium is also a critical component for ceramics, glass, metallurgy, air treatment products, pharmaceuticals, and polymers [4]. Lithium is used to make alloys with other metals including lead, copper, silver, magnesium, silicon, and aluminum. The alloys most commonly used in aerospacePDF Image | Recovery of Lithium from Geothermal Brines

PDF Search Title:

Recovery of Lithium from Geothermal BrinesOriginal File Name Searched:

energies-14-06805-v2.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |