PDF Publication Title:

Text from PDF Page: 014

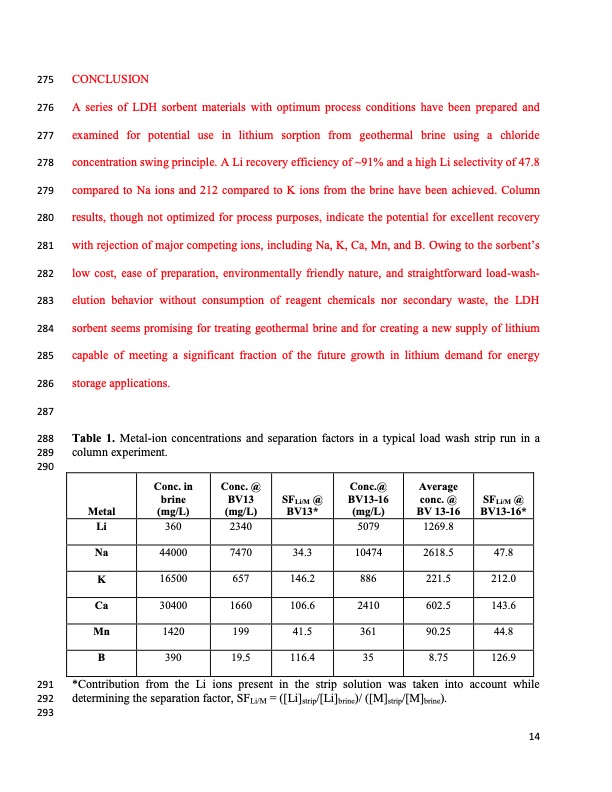

275 CONCLUSION 276 A series of LDH sorbent materials with optimum process conditions have been prepared and 277 examined for potential use in lithium sorption from geothermal brine using a chloride 278 concentration swing principle. A Li recovery efficiency of ~91% and a high Li selectivity of 47.8 279 compared to Na ions and 212 compared to K ions from the brine have been achieved. Column 280 results, though not optimized for process purposes, indicate the potential for excellent recovery 281 with rejection of major competing ions, including Na, K, Ca, Mn, and B. Owing to the sorbent’s 282 low cost, ease of preparation, environmentally friendly nature, and straightforward load-wash- 283 elution behavior without consumption of reagent chemicals nor secondary waste, the LDH 284 sorbent seems promising for treating geothermal brine and for creating a new supply of lithium 285 capable of meeting a significant fraction of the future growth in lithium demand for energy 286 storage applications. 287 288 Table 1. Metal-ion concentrations and separation factors in a typical load wash strip run in a 289 column experiment. 290 Metal Conc. in brine (mg/L) Conc. @ BV13 (mg/L) SFLi/M @ BV13* Conc.@ BV13-16 (mg/L) Average conc. @ BV 13-16 SFLi/M @ BV13-16* Li Na K Ca Mn B 360 2340 44000 7470 16500 657 30400 1660 1420 199 390 19.5 34.3 146.2 106.6 41.5 116.4 5079 1269.8 10474 2618.5 886 221.5 2410 602.5 361 90.25 35 8.75 47.8 212.0 143.6 44.8 126.9 291 *Contribution from the Li ions present in the strip solution was taken into account while 292 determining the separation factor, SFLi/M = ([Li]strip/[Li]brine)/ ([M]strip/[M]brine). 293 14PDF Image | Recovery of Lithium from Geothermal Brine Li AL

PDF Search Title:

Recovery of Lithium from Geothermal Brine Li ALOriginal File Name Searched:

1424451.pdfDIY PDF Search: Google It | Yahoo | Bing

Product and Development Focus for Infinity Turbine

ORC Waste Heat Turbine and ORC System Build Plans: All turbine plans are $10,000 each. This allows you to build a system and then consider licensing for production after you have completed and tested a unit.Redox Flow Battery Technology: With the advent of the new USA tax credits for producing and selling batteries ($35/kW) we are focussing on a simple flow battery using shipping containers as the modular electrolyte storage units with tax credits up to $140,000 per system. Our main focus is on the salt battery. This battery can be used for both thermal and electrical storage applications. We call it the Cogeneration Battery or Cogen Battery. One project is converting salt (brine) based water conditioners to simultaneously produce power. In addition, there are many opportunities to extract Lithium from brine (salt lakes, groundwater, and producer water).Salt water or brine are huge sources for lithium. Most of the worlds lithium is acquired from a brine source. It's even in seawater in a low concentration. Brine is also a byproduct of huge powerplants, which can now use that as an electrolyte and a huge flow battery (which allows storage at the source).We welcome any business and equipment inquiries, as well as licensing our turbines for manufacturing.| CONTACT TEL: 608-238-6001 Email: greg@infinityturbine.com | RSS | AMP |